Fabricated composite wall based on steel pipes and construction method thereof

A composite wall and prefabricated technology, which is applied in the processing of walls, building materials, building components, etc., can solve the problems of low vertical and horizontal bearing capacity of dense rib composite walls, unclear connection design of key nodes of composite walls, etc. The effect of saving the amount of steel used, improving the bearing capacity, seismic performance, and strong compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

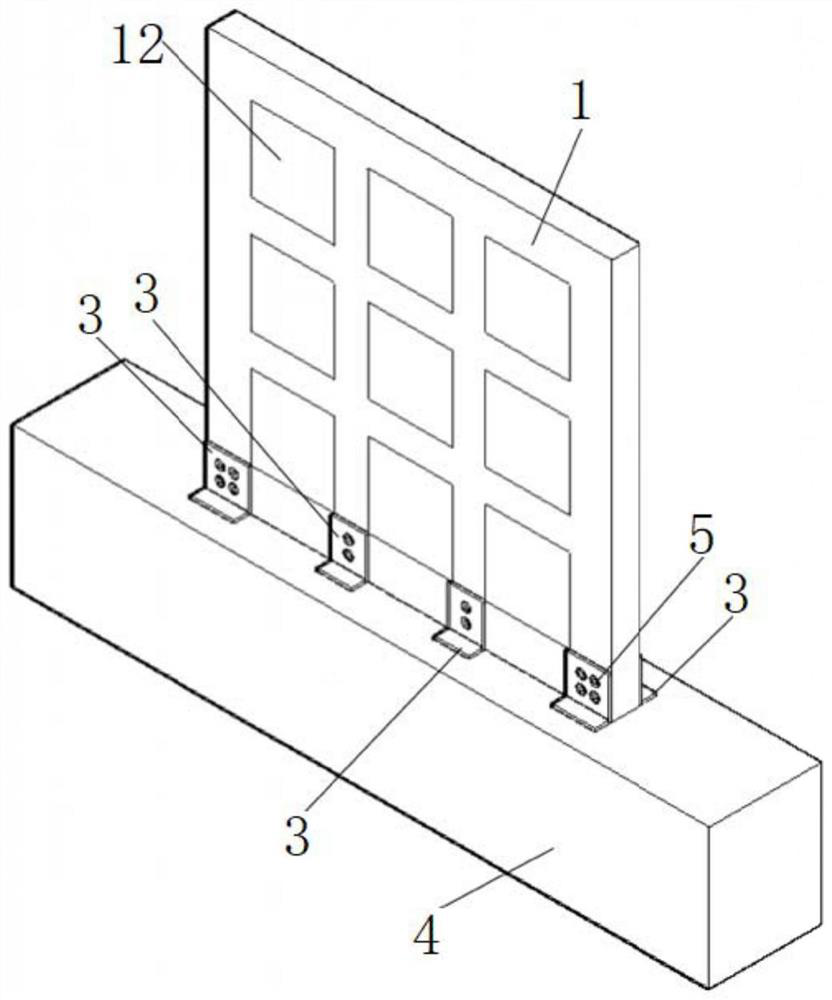

[0041] as attached Figure 1-5As shown, this embodiment provides a prefabricated composite wall based on steel pipes, including a prefabricated wall panel 1, a wall connector 2 and a foundation embedded part 3, the prefabricated wall panel 1 is arranged on the foundation beam 4; the prefabricated wall panel 1 Including steel pipe composite wall skeleton 11, blocks 12 and concrete outer cladding, the steel pipe composite wall skeleton 11 adopts a rib structure formed by assembling and welding multiple steel pipes, the rib lattice structure is filled with blocks 12, and the concrete outer cladding is wrapped in ribs On the outside of the lattice structure, the surroundings of the block 12 are bonded with the concrete outer cladding. Preferably, the blocks 12 are made of aerated concrete blocks, and the aerated concrete blocks are made of recycled aggregate concrete instead of traditional concrete materials, which can effectively alleviate the consumption of raw materials and the...

Embodiment 2

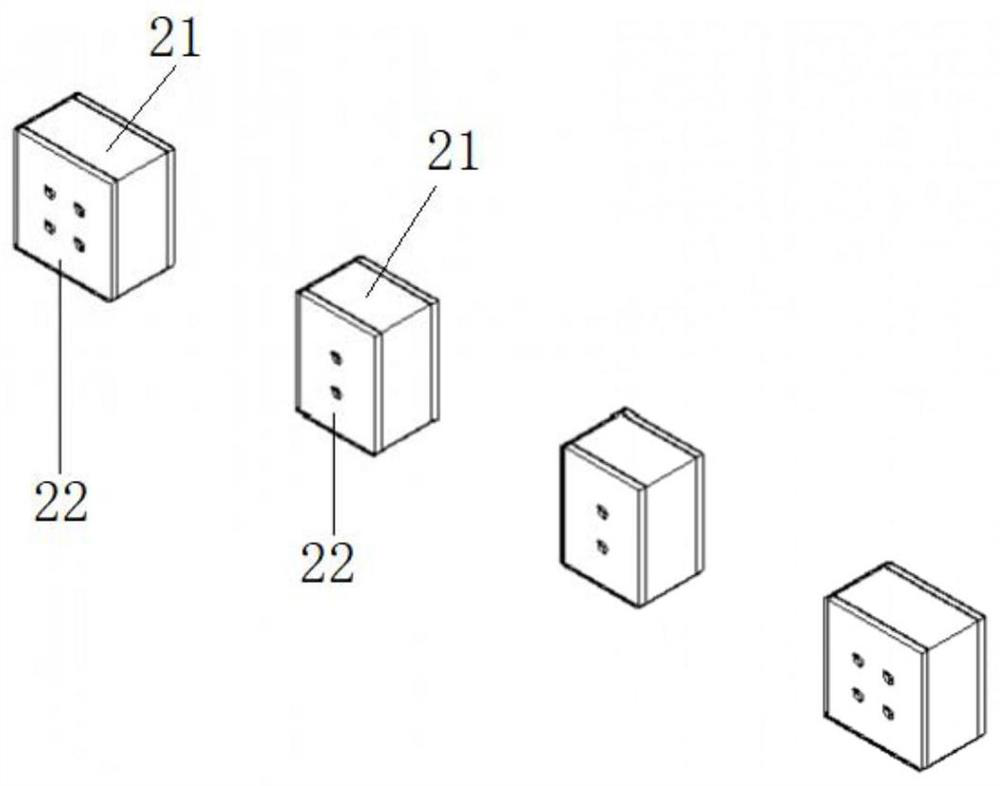

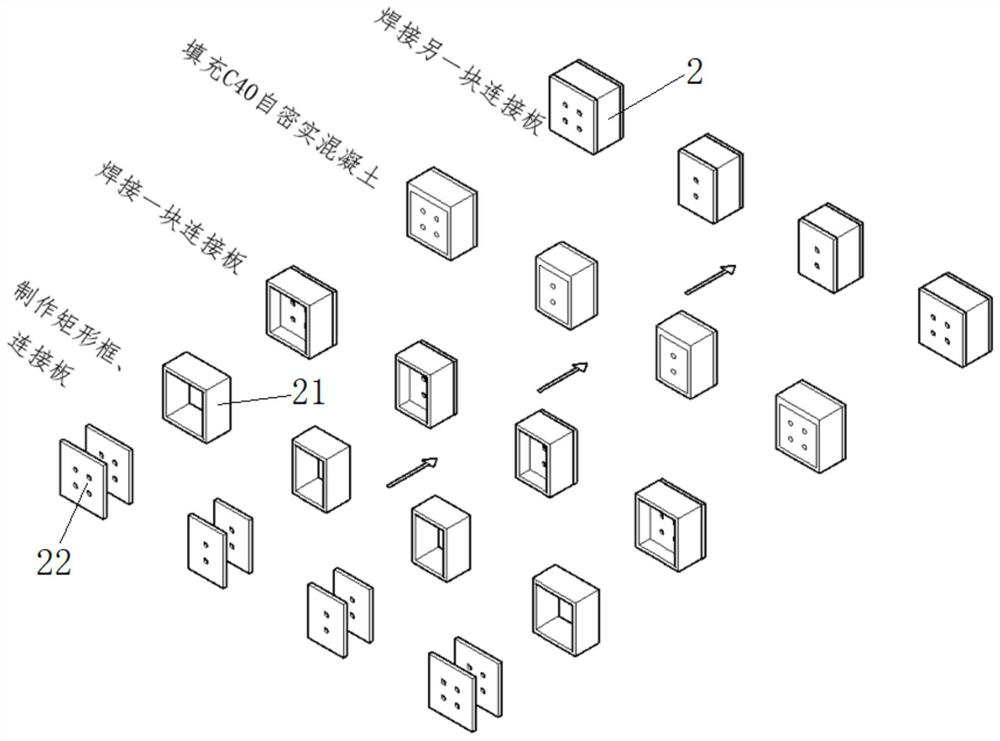

[0059] as attached Figure 1-4 , 6, the structural design principle and manufacturing process of embodiment 2 and embodiment 1 are basically the same, the difference is that the side rib column 111, the middle rib column 112, the upper rib beam 113, and the lower rib column in the steel pipe composite wall skeleton Both the rib beam 114 and the middle rib beam 115 are rectangular steel pipes.

[0060] In this embodiment 2, the frame of the steel pipe compound wall is welded by rectangular steel pipes in the factory. By setting rib column end plates at the ends of the rectangular steel pipes, the rectangular steel pipes in the steel pipe composite wall skeleton are all sealed structures. After the steel pipes are sealed, their The internal air cannot circulate, so the heat cannot be effectively transferred, which effectively improves the thermal insulation effect of the prefabricated composite wall; by sealing the ends of the rectangular steel pipes, it is ensured that there is...

Embodiment 3

[0063] as attached Figure 1-4 , 7, the structural design principle and manufacturing process of embodiment 3 and embodiment 2 are basically the same, the difference is that the side rib column 111, the middle rib column 112, the upper rib beam 113, the lower rib column in the steel pipe composite wall skeleton The rib beam 114 and the middle rib beam 115 are both made of rectangular steel pipes, the webs of which are parallel to the surface of the prefabricated wall panel 1, and the webs of the rectangular steel pipes are evenly provided with circular or elliptical through holes.

[0064] In this embodiment 3, circular or elliptical through holes should be opened according to the design requirements in the webs of rectangular steel pipe beams and rectangular steel pipe beam columns, so as to facilitate concrete pouring; both ensured the pouring quality of concrete when making wall panels, and To a certain extent, the bonding strength between steel and concrete is enhanced, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com