Amino acid water-soluble solid fertilizer special for phalaenopsis amabilis and preparation method thereof

A solid fertilizer, amino acid technology, applied in the field of Phalaenopsis planting, can solve the problem of no Phalaenopsis and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

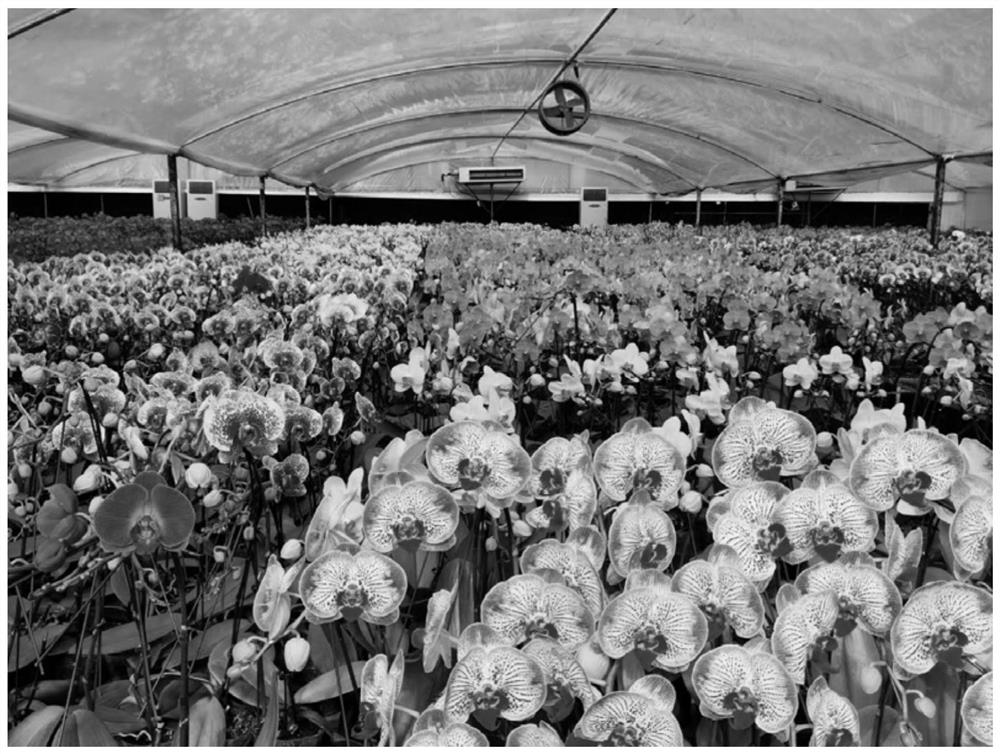

Image

Examples

Embodiment 1

[0021] Ingredients for Phalaenopsis Amino Acid Water Amino Acid Water-Soluble Solid Fertilizer: To produce 1 ton of this fertilizer, 260kg of compound amino acid powder, 70kg of urea, 210kg of potassium dihydrogen phosphate, 200kg of magnesium sulfate heptahydrate, 100kg of zinc sulfate heptahydrate, 154kg of borax, molybdenum Ammonium acid 6kg, a total of 1000kg. The compound amino acid powder adopts the compound amino acid produced by Xinxiang Chemical Industry Research Institute of Henan Province. It is a product made of natural keratin protein and plant protein as raw materials, hydrolyzed with hydrochloric acid, and then processed by a series of processes such as decolorization, deacidification, desalination, and spray drying. Contains aspartic acid, glutamic acid, serine, glycine, histidine, arginine, threonine, alanine, proline, tyrosine, valine, methionine, cystine , isoleucine, leucine, phenylalanine, tryptophan, lysine and other 18 kinds of free amino acids. The mas...

Embodiment 2

[0031] Ingredients of Phalaenopsis Amino Acid Water Amino Acid Water-Soluble Solid Fertilizer: To produce 1 ton of this fertilizer, 300kg of compound amino acid powder, 80kg of urea, 220kg of potassium dihydrogen phosphate, 180kg of magnesium sulfate heptahydrate, 50kg of zinc sulfate heptahydrate, 164kg of borax, molybdenum Ammonium acid 6kg, a total of 1000kg. The compound amino acid powder adopts the compound amino acid produced by Xinxiang Research Institute of Chemical Industry, Henan Province, the same as in Example 1.

[0032] Preparation steps:

[0033] Specifically, its preparation method comprises the following steps:

[0034] 1) Take all the components according to the ratio, pulverize them, and pass through an 80-mesh sieve;

[0035] 2) Fully mix the crushed and sieved components until the color is uniform;

[0036] 3) Press the fully mixed components into a spherical granular fertilizer with a diameter of 1.0mm to 4.75mm;

[0037] 4) drying the spherical granu...

Embodiment 3

[0041] Ingredients of Phalaenopsis Special Amino Acid Water Amino Acid Water-Soluble Solid Fertilizer: To produce 1 ton of this fertilizer, 280kg of compound amino acid powder, 100kg of urea, 210kg of potassium dihydrogen phosphate, 180kg of magnesium sulfate heptahydrate, 70kg of zinc sulfate heptahydrate, 154kg of borax, molybdenum Ammonium acid 6kg, a total of 1000kg. The compound amino acid powder adopts the compound amino acid produced by Xinxiang Research Institute of Chemical Industry, Henan Province, the same as in Example 1.

[0042] Preparation steps:

[0043] Specifically, its preparation method comprises the following steps:

[0044] 1) Take all the components according to the ratio, pulverize them, and pass through an 80-mesh sieve;

[0045] 2) Fully mix the crushed and sieved components until the color is uniform;

[0046] 3) Press the fully mixed components into a spherical granular fertilizer with a diameter of 1.0mm to 4.75mm;

[0047] 4) drying the spheri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com