Preparation method of PVC aerogel co-agent foam board

A PVC board and aerogel technology, applied in the field of architectural decoration, can solve the problems of poor thermal insulation performance and noise reduction performance of composite boards, poor flame retardant and fireproof performance, and failure to meet the fire protection level, etc., to achieve good heat preservation and heat insulation performance, Improved fire performance, bright and colorful decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

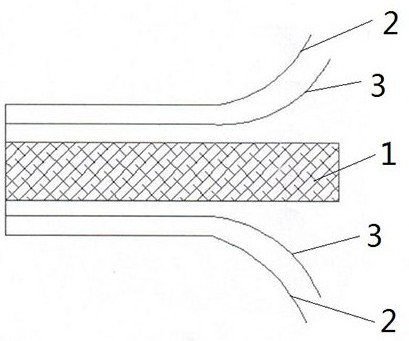

[0027] Refer to attached figure 1 , this embodiment provides a preparation method of a PVC airgel co-agent foamed board, specifically, the PVC airgel co-agent foamed board includes a core material layer 1, and the upper and lower surfaces of the core material layer 1 are both An adhesive layer 3 and a metal layer 2 are provided in sequence.

[0028] Wherein, the core material layer 1 is filled with aerogel in the PVC board, and through the action of grafting agent, it is fused with each other to form the core material layer 1, and the proportion of airgel in the main core material reaches 0.5%-30%. . The metal layer 2 is a thin metal plate, and the thickness of the thin metal plate is 0.1-1mm; in addition, the thin metal plate can be a coated metal coil made of aluminum alloy, but it is not limited thereto. The adhesive layer 3 is a polymer film, and the polymer film is an aluminothermic composite polymer film in the prior art. The composite temperature of the aluminothermic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com