Bright color composite reinforced board

A reinforced board, bright color technology, applied in chemical instruments and methods, synthetic resin layered products, building components and other directions, can solve the problems of small connection span, poor surface decoration effect, low rigidity of board surface, etc., to achieve aging resistance Performance, colorful, good stiffness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] The specifications of the bright color composite reinforced board described in this embodiment are: flat plate, length 8.4m*width 2.5m, board thickness 21mm, inner and outer strength layer 4 thick 3mm, support layer 6 thickness 15mm, outer surface red (Chinese red ), surface requirements: show pearlescent and crystalline effects during the day, reflective and fluorescent (spotlight irradiation) effects at night.

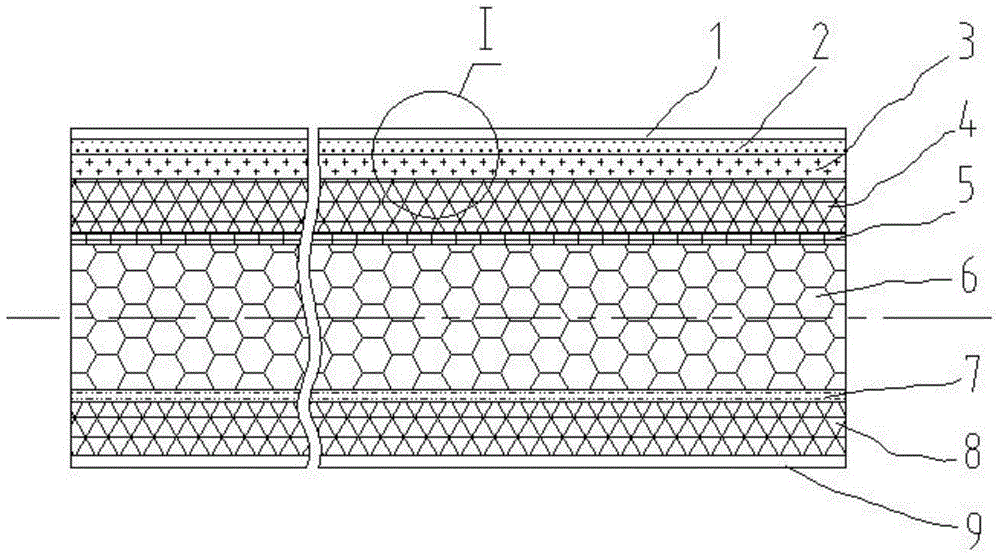

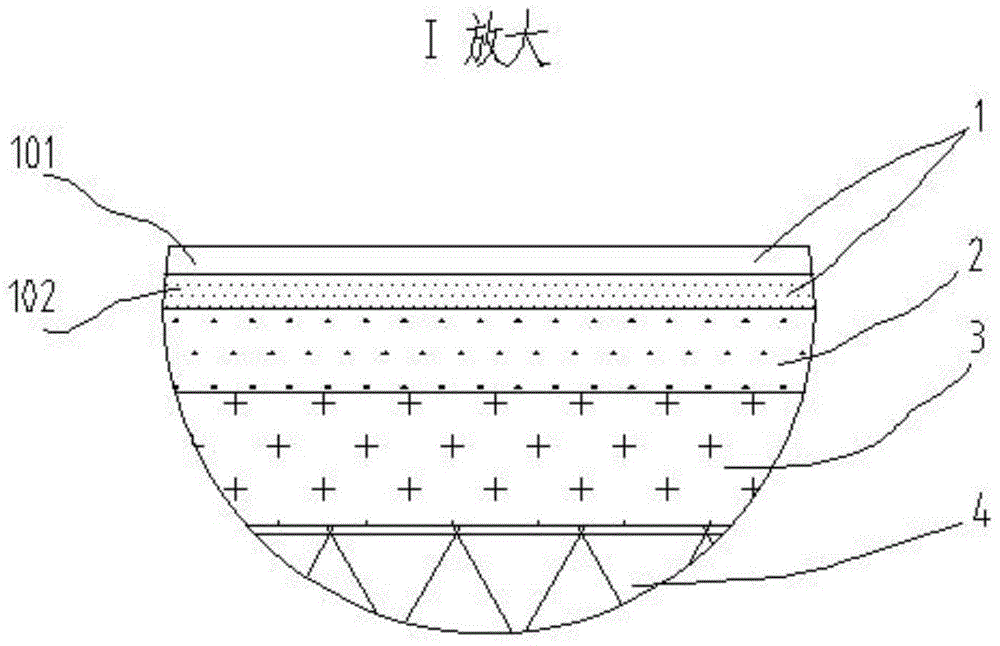

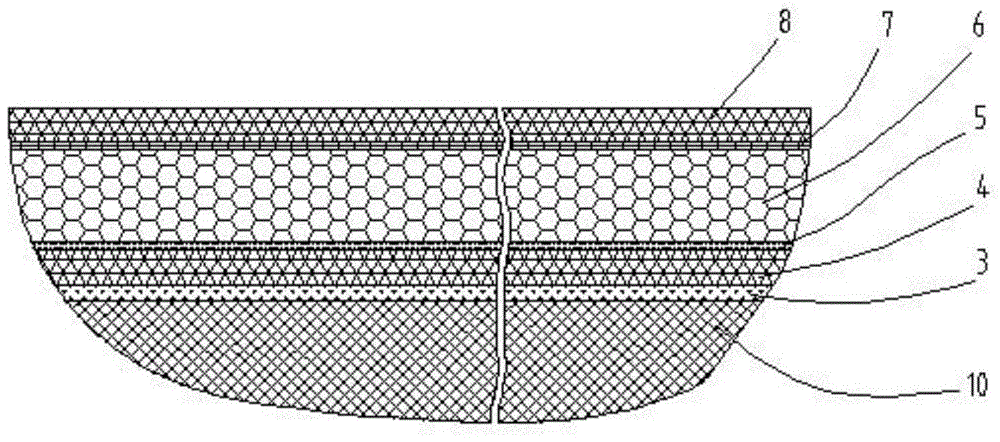

[0078] Such as Figure 1~3 As shown, the section of the Liangcai composite strengthened plate in this embodiment adopts a multi-layer composite structure, which sequentially includes a bright film layer 1, a crystal layer 2, a reflective layer 3, an outer strength layer 4, a transition layer 5, and a support layer from the outside to the inside. 6. Inner lining layer 7, inner strength layer 8 and interior trim layer 9.

[0079] In this embodiment, a contact mold is used for production, and the material of the mold is glass fiber reinforced plastic (FRP). The...

Embodiment 2

[0103] The specifications of the crystal-color composite reinforced plate described in this embodiment are: spherical crown, ball diameter Φ3m*height 0.75m, plate thickness 21mm, inner and outer strength layer 4 thick 3mm, support layer 6 thick 15mm, outer surface red (China Red), surface requirements: show pearlescent and crystalline effects during the day, and show reflective (spotlight irradiation) and translucent (internal lighting) effects at night.

[0104] Such as figure 1 , 2 , Shown in 4, the sectional structure of the crystal-color composite reinforced plate of the present embodiment is the same as that of the embodiment 1. This embodiment is produced by a concave contact mold, the mold material is FRP, and the production steps are as follows:

[0105] a) Same as the production steps a) to e) in Example 1, note: In this example, the resin in the material ratio MF4 is changed to 3559 light-transmitting resin.

[0106] b) Laying the support layer 6 First, prepare a ...

Embodiment 3

[0110] The specifications of the bright color composite reinforced board described in this embodiment are: curved board, curved surface radius Φ2m*board width 2m*curved surface arc length 1.2m, board thickness 28mm, inner and outer strength layer 4 thick 4mm, support layer 6 thickness 20mm, outer The surface is red (Chinese red), and the surface requirements: show pearlescent and crystal brilliance effects during the day, and show fluorescence and reflections at night (spotlight irradiation).

[0111] Such as figure 1 , 2 As shown in , 5, the difference between the section structure of the bright color composite reinforced plate of this embodiment and that of Embodiment 1 is that the positions of the transition layer 5 and the inner lining layer 7 are exchanged.

[0112] The difference between the manufacturing method of this embodiment and that of Embodiment 2 is that: production is carried out using a convex contact mold; in step b), the scored surface of the polypropylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com