Transverse-structure IMPATT diode and preparation method thereof

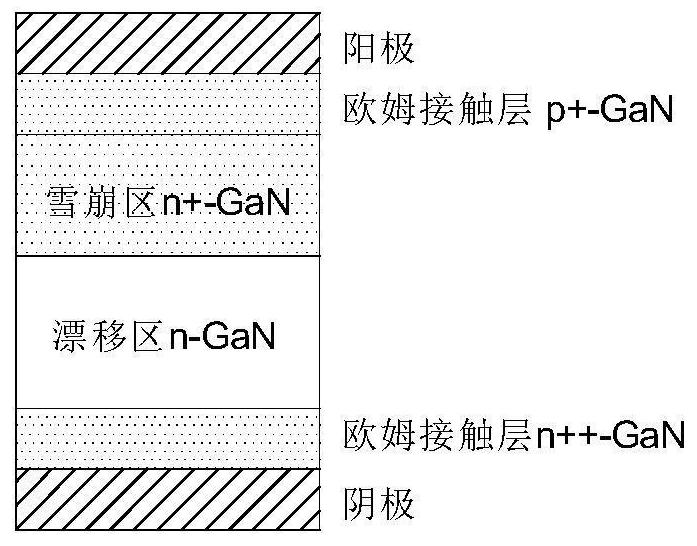

A technology of lateral structure and diode, which is applied in the direction of diode, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficult to obtain, immature process manufacturing technology, and limited charge packet concentration, so as to achieve high output power performance and work Frequency performance, significant negative differential mobility effect, effect of reduced ionized impurity scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

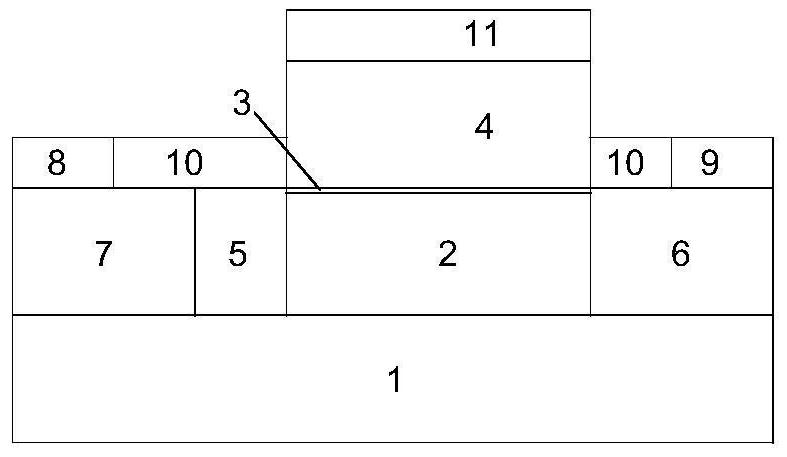

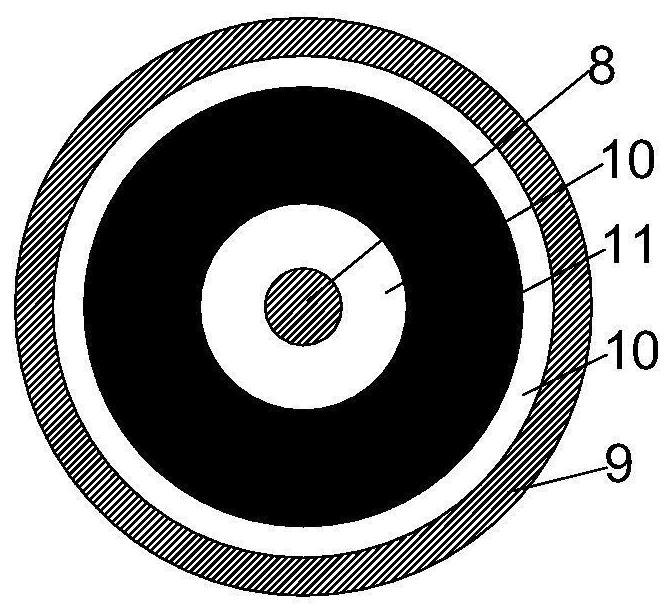

[0042] refer to figure 2 , the lateral structure IMPATT diode of the present invention comprises a substrate layer 1, an epitaxial layer 2, a drift layer 3, an n-AlGaN barrier layer 4, an n+-GaN barrier layer 5, a right ohmic contact layer 6, a left ohmic contact layer 7, a left Ohmic contact electrode 8 , right ohmic contact electrode 9 , passivation layer 10 , Schottky contact electrode 11 .

[0043] The epitaxial layer 2 is located on the upper layer of the substrate layer 1; the drift layer 3 is a two-dimensional electron gas thin layer formed on the top of the epitaxial layer 2 when electricity is applied; the n-AlGaN barrier layer 4 is located on the upper layer of the drift layer 3; n+-GaN The barrier layer 5 is located on the upper layer of the substrate layer 1 and on the left side of the epitaxial layer 2;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com