Preparation method of wheat germ oil with high nutritional value

A wheat germ oil and wheat germ technology, which is applied in the direction of fat oil/fat refining, fat oil/fat production, fat production, etc., can solve the problems of destroying nutrients such as protein, low extraction efficiency, and revealing the retention rate, and achieve the protection of nutrients. , Overcome the effect of low oil extraction rate and high yield extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of high nutritional value wheat germ oil, comprising the steps of:

[0025] (1) Screening and cleaning treatment: put the wheat germ into the screening machine for screening, remove the damaged wheat germ, then put the screened wheat germ into clean water, and then use ultrasonic waves with a frequency of 600~700kHz , after ultrasonic cleaning for 20-30 minutes, take it out for later use; the drying oven used in the drying process is a hot air drying oven or a far-infrared drying oven, and the temperature in the drying oven is controlled not to exceed 70°C during the drying process;

[0026] (2), drying treatment: put the wheat germ treated in step (1) into a drying box for drying treatment, control the water content in the wheat germ to 18-20%, and then take it out for later use;

[0027] (3), low-temperature freezing treatment: put the wheat germ processed in step (2) into the freezer, control the accumulation thickness of the wheat germ in the fr...

Embodiment 1

[0034] A preparation method of high nutritional value wheat germ oil, comprising the steps of:

[0035] (1) Screening and cleaning treatment: Put the wheat germ into the screening machine for screening treatment, remove the damaged wheat germ, put the screened wheat germ into clean water, and then use ultrasound with a frequency of 600kHz, ultrasonic After cleaning for 20 minutes, take it out for use; the drying box used in the drying process is a hot air drying box, and the temperature in the drying box is controlled at 65~70°C during the drying process;

[0036] (2), drying treatment: put the wheat germ treated in step (1) into a drying box for drying treatment, control the water content in the wheat germ to 18-20%, and then take it out for later use;

[0037] (3), low-temperature freezing treatment: put the wheat germ processed in step (2) into the freezer, control the accumulation thickness of the wheat germ in the freezer to be no more than 10cm, and then carry out low-te...

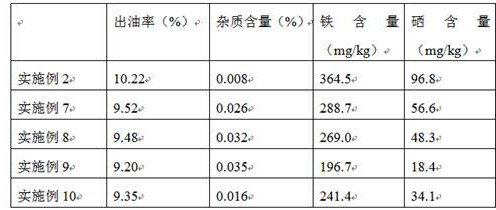

Embodiment 2

[0044] A preparation method of high nutritional value wheat germ oil, comprising the steps of:

[0045] (1) Screening and cleaning treatment: Put the wheat germ into the screening machine for screening treatment, remove the damaged wheat germ, put the screened wheat germ into clean water, and then use ultrasound with a frequency of 650kHz, ultrasonic After cleaning for 25 minutes, take it out for use; the drying box used in the drying process is a hot air drying box, and the temperature in the drying box is controlled at 60~65°C during the drying process;

[0046] (2), drying treatment: put the wheat germ treated in step (1) into a drying box for drying treatment, control the water content in the wheat germ to 18-20%, and then take it out for later use;

[0047] (3), low-temperature freezing treatment: put the wheat germ processed in step (2) into the freezer, control the accumulation thickness of the wheat germ in the freezer to be no more than 8cm, and then carry out the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com