A weighing type liquid color masterbatch machine and its automatic calibration method and application

An automatic calibration and liquid technology, applied in the field of polymer material processing, can solve the problems of low single filling amount of liquid color masterbatch, large measuring range, and inability to realize the gradual aging of the metering pump tube, so as to ensure the accuracy and improve the The effect of accuracy and precision correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

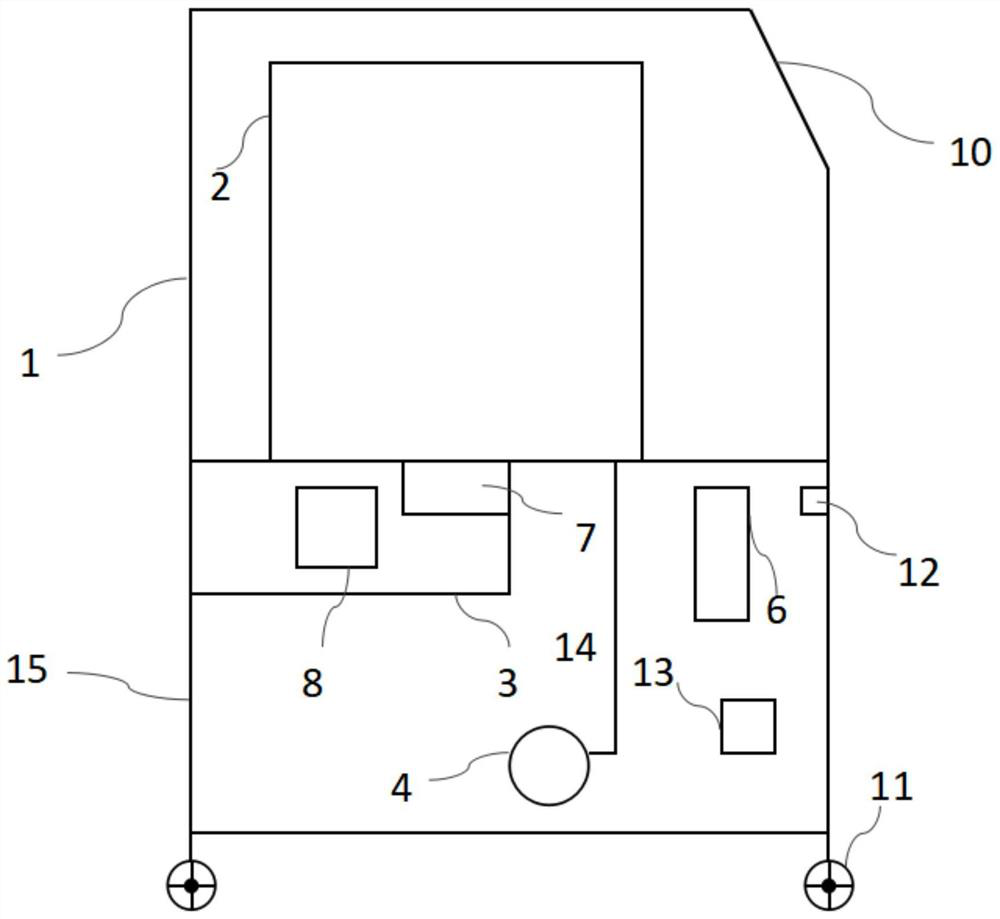

[0042] see figure 1 shown. A weighing type liquid masterbatch machine, comprising a liquid color masterbucket 2, a weighing system 3, a delivery pump 4, a support box 15, a limit alarm device 12, a control system 6 and a calibration module 13; the liquid color masterbatch 2 The hose 14 is used to connect with the delivery pump 4; the weighing system 3, the delivery pump 4, the limit alarm device 12 and the correction module 13 are connected with the control system 6 through signal lines.

[0043] The material of the liquid masterbatch bucket 2 is a plastic bucket. The volume of the liquid masterbatch bucket 2 is 10L. The weighing system 3 includes a weighing sensor 7 and a weighing transmission module 8 . The control system 6 is realized by a single-chip microcomputer. The delivery pump 4 is a peristaltic pump. A windproof box 1 is arranged on the outside of the liquid masterbatch barrel 2 . Rollers 11 are installed at the four corners of the bottom of the liquid color m...

Embodiment 2

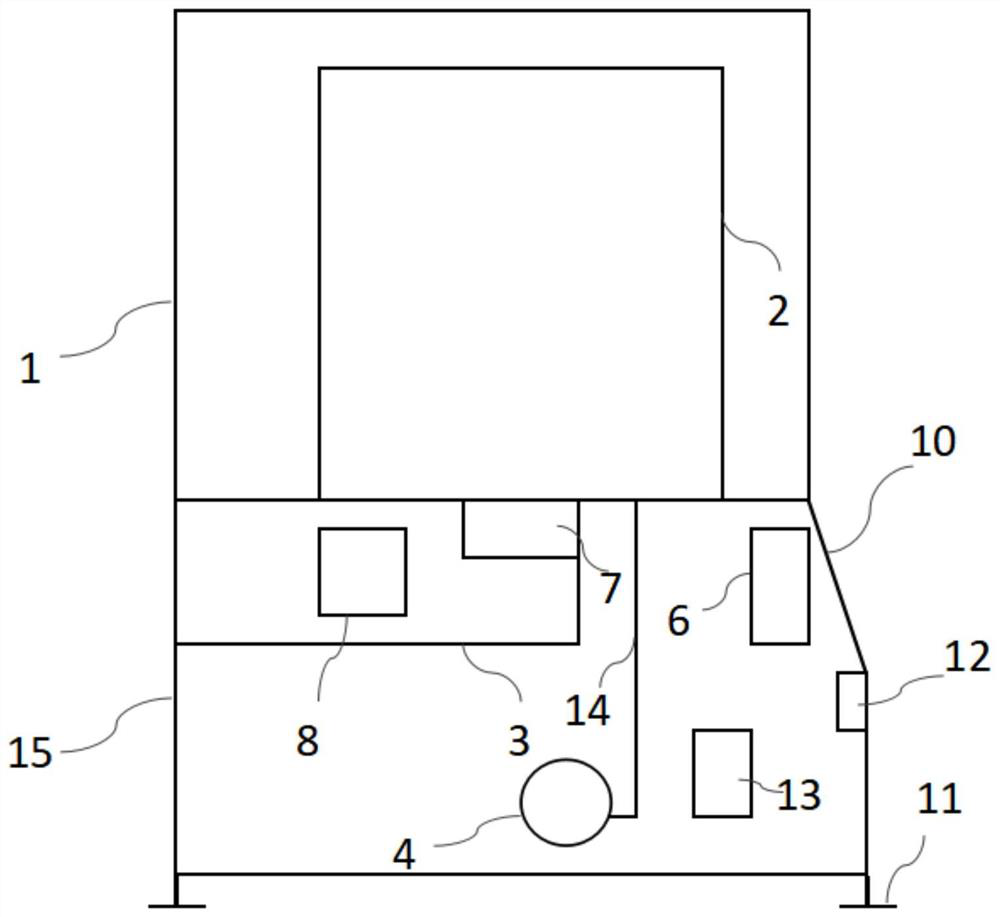

[0046] The invention relates to a weighing type liquid color masterbatch machine, which comprises a liquid color masterbatch bucket 2, a weighing system 3, a delivery pump 4, a support box 15, a limit alarm device 12, a control system 6 and a correction module 13. A hose 14 is used to connect the liquid color masterbatch 2 and the delivery pump 4 . The weighing system 3 , delivery pump 4 , limit alarm device 12 and calibration module 13 are connected to the control system 6 through signal lines.

[0047] The material of the liquid color mother barrel 2 is a stainless steel barrel. The volume of the liquid color masterbatch 2 is 20L. The weighing system 3 includes an electronic scale 7 and a weight output module 8 . The control system 6 is realized through PLC control. The delivery pump 4 is a gear pump. A windproof box 1 is arranged on the outside of the liquid masterbatch barrel 2 . Feet 11 are installed at the four corners of the bottom of the liquid color masterbatch m...

Embodiment 3

[0050] In combination with the weighing type liquid color masterbatch machine described in Embodiment 1 and 2, the position distribution and function of each component are described as follows:

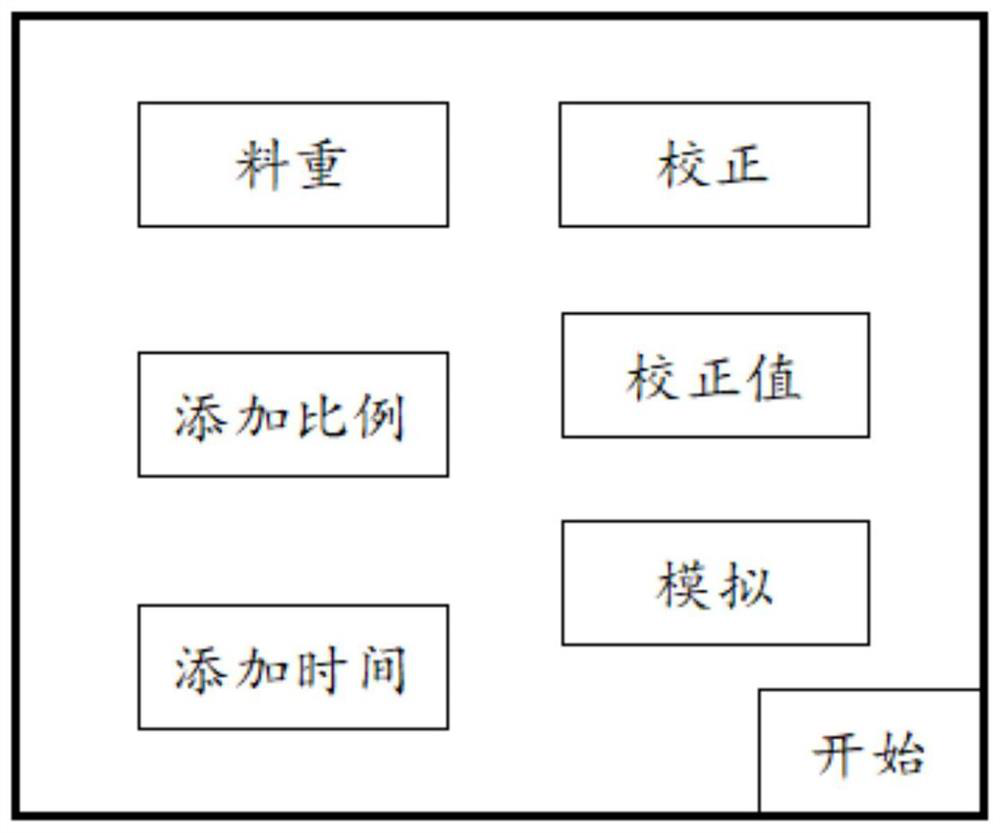

[0051] The weighing type liquid color masterbatch machine is mainly used to realize precise and quantitative delivery of liquid color masterbatch to processing equipment. Embodiment 1 The touch display screen 10 is placed on the side of the windproof box 1, and the touch display screen 10 described in Embodiment 2 is placed on the side of the support box 15. Manually input the material weight of the plastic used each time, the addition ratio of the liquid masterbatch, the addition time, and the correction cycle; the correction cycle described in Example 1 is related to the addition time, and has a multiple relationship with the addition time, and the manual input correction cycle is 5 times, the addition time is 10s, then the correction period is 50s; the correction period described i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com