Refined manufacturing of photo-control-hybridized cross-linked degradable support and bone tissue engineering application of photo-control-hybridized cross-linked degradable support

A photocrosslinking and osteogenesis technology, applied in tissue regeneration, inorganic chemistry, additive processing, etc., can solve the problems of poor mechanical properties, high toxicity of chemical crosslinking agents, and fast degradation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

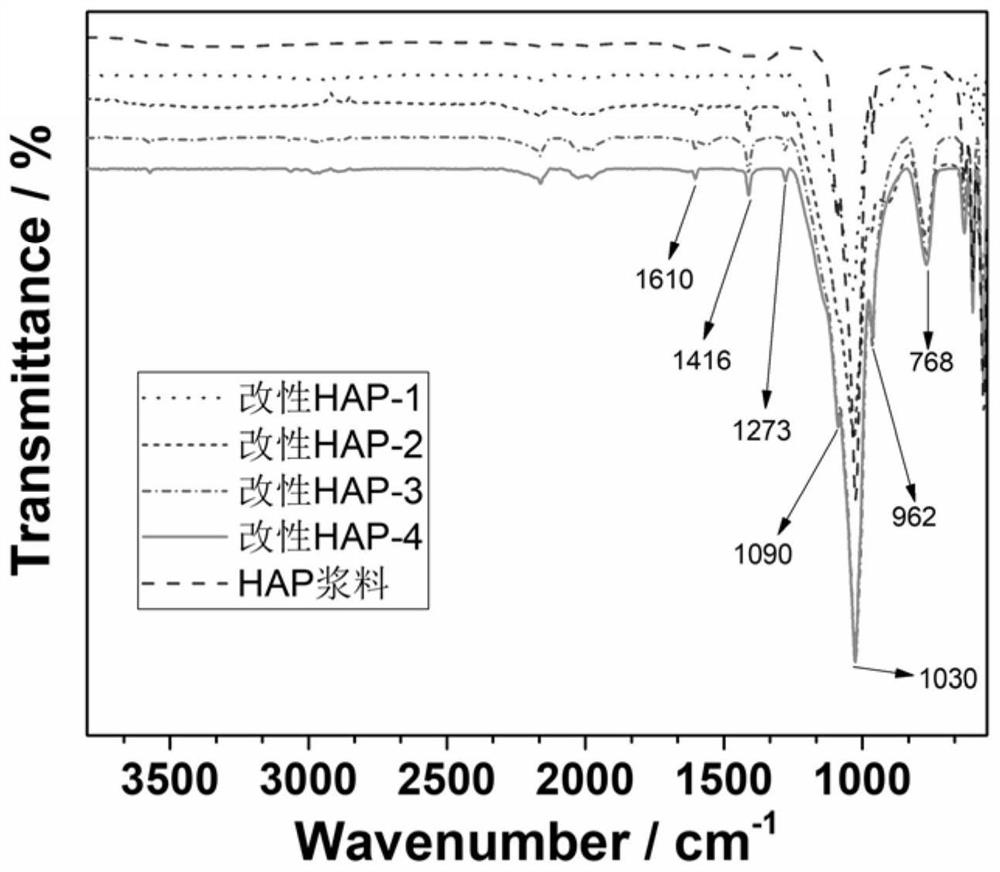

[0088] This embodiment discloses a method for preparing a double bond modified hydroxyapatite slurry, and the specific steps are as follows:

[0089] (1) Dosing: the volume ratio of ethanol and water is 6:1, 7:1, 8:1, and 9:1 respectively to obtain a solution, and the pH value is adjusted to 4.0 with glacial acetic acid;

[0090] In this step, the ethanol:water volume ratios are 6:1, 7:1, 8:1, and 9:1, which are recorded as experimental groups ①, ②, ③, and ④ respectively.

[0091] (2) Hydrolysis reaction: Take the ethanol-water solution prepared in step (1), stir it with a magnetic stirrer, and slowly add 5ml of ethyl orthosilicate and vinyltriethoxysilane in a volume ratio of 1:1. solution, stirred at room temperature for 1 h;

[0092] (3) Condensation reaction: slowly drop 20ml of hydroxyapatite slurry into the mixed solution prepared in step (2), stir and react at room temperature for 1.5h to obtain a mixed solution;

[0093] (4) Add dropwise 10wt% NaOH solution to the mi...

Embodiment 2

[0104] This embodiment discloses the preparation method of methacrylic anhydride gelatin, and concrete steps are as follows:

[0105] (1) Dosing: Dissolve gelatin in PBS buffer at a concentration of 10% (w / v), and stir well at 50°C until the gelatin is completely dissolved;

[0106] (2) Add methacrylic anhydride MA (0.8ml~1.2mLMA per gram of gelatin) dropwise to the gelatin solution prepared in step (1) at a rate of 0.5ml per minute, and fully stir the reaction while maintaining 50°C 3h;

[0107] In this step, the ratio (v / w) of methacrylic anhydride to gelatin is: 0.6:1, 0.8:1, 1:1, 1.2:1. Record them as experimental groups A, B, C, and D respectively;

[0108] (3) After the reaction is completed, the product obtained in step 2 is transferred to a centrifuge tube, centrifuged at 1500rpm for 5min, and the supernatant is taken and packed into a dialysis bag;

[0109] (4) Dialysis: dialyze the product obtained in step 3 in pure water at 50° C. for at least 3 days, and change ...

Embodiment 3

[0117] The GELMA of experimental group C was configured as a hydrogel with a concentration of 15% (w / v) and placed on a dynamic mechanical analyzer (TAInstruments Q800, USA), and the hydrogel was measured in the multi-frequency mode (0.1-100rad / s). The change curves of elastic modulus (G′) and viscous modulus (G″), the results are shown in the attached Figure 6 shown. Under the test condition that the amplitude is fixed at 0.5%, the frequency is in the range of 0.1-100rad / s, the elastic modulus G' is greater than the viscous modulus G", the material shows obvious hydrogel characteristics, and the elastic modulus G ′ and viscosity modulus G″ both show a strong frequency dependence, which increases with the increase of frequency, and the values are 0.01Pa~139Pa and 0.01Pa~72Pa, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com