Preparation method of composite PZT piezoelectric film based on sol-gel method and electrojet deposition method

A technology of piezoelectric film and electric jet, which is applied in the coupling of optical waveguide, the process for producing decorative surface effects, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of poor combination with electrodes and surface Large roughness and other problems, to achieve the effect of promoting preferred orientation, reducing surface roughness, and good bonding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

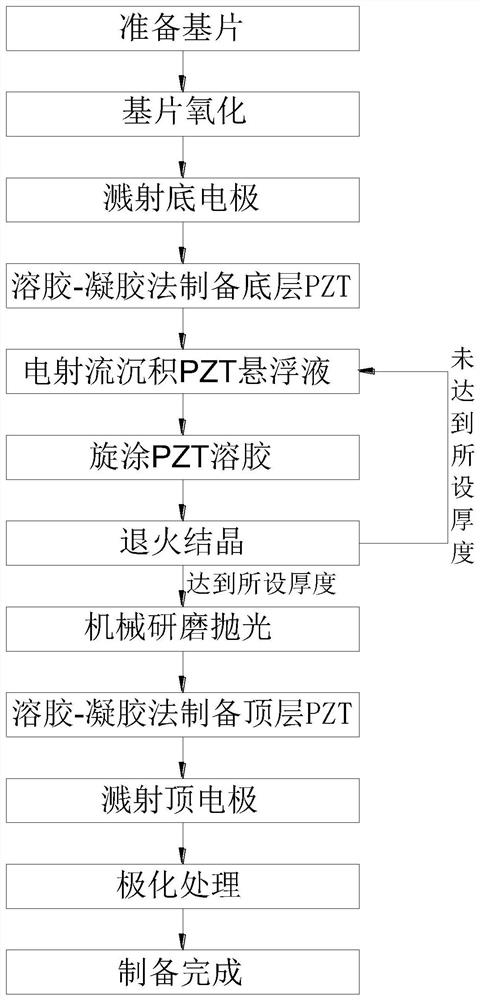

[0030] like figure 2 As shown, the composite PZT piezoelectric film based on the sol-gel method and the electrojet deposition method, the specific steps of its preparation are as follows:

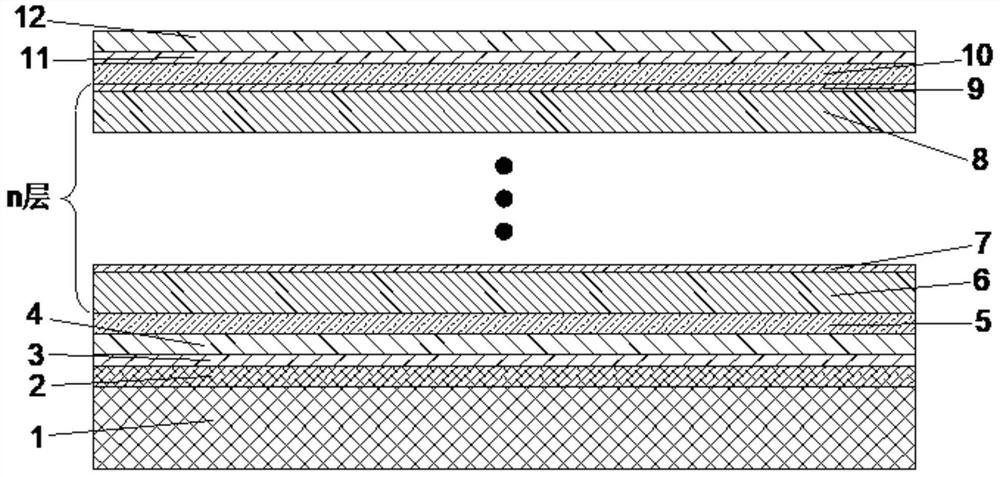

[0031] Step 1: Prepare a substrate, which is an n-type (100) single-sided polished single-crystal silicon wafer with a thickness of 250 μm, and is ready for use after cleaning. figure 1 Structure 1.

[0032] Step 2, substrate oxidation, dry oxygen oxidation of SiO with a thickness of 600nm 2 Insulation. figure 1 Structure 2.

[0033] Step 3, sputtering the bottom electrode, magnetron sputtering Ti (50nm) / Pt (200nm) metal electrode layer. figure 1 Structure 3 and Structure 4.

[0034] Step 4, prepare the bottom layer PZT by sol-gel method, configure PZT sol, spin coating (low speed 600r / min, coating time 9s, high speed 3000r / min, coating time 30s), dry pyrolysis (at 180°C Under the condition of heating for 5 minutes, then heating at 350°C for 5 minutes) and double-layer annealing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com