Novel L-shaped pressure sensor clamp

A sensor and pressure technology, applied in the direction of supporting machines, mechanical equipment, machines/supports, etc., can solve the problems of unsatisfactory sealing effect, reduced work efficiency, accelerated wear and scrap of sealing rings and gaskets, etc., to improve the test The effect of success rate, improving work efficiency and reducing installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

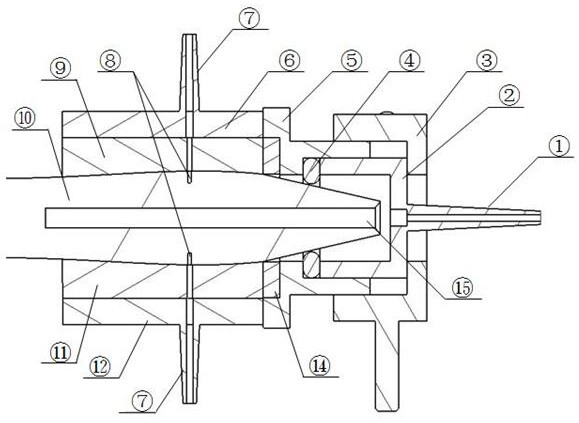

[0019] A novel L-shaped pressure receptor 10 fixture includes an upper casing 6 and a lower casing 12 for fixing the L-shaped pressure receptor 10, and one end of the upper casing 6 and the lower casing 12 is connected with the main body 5 at the same time. Connected, the main body 5 is provided with a sealing ring 4, the main body 5 is provided with a tightening handwheel 3 and a compression sleeve 2, and one end of the main body 5 is provided with a total pressure pipe joint 1. The static pressure part of the special fixture for the L-shaped pressure sensor 10 is clamped and installed up and down, so that the gasket is deformed to ensure a reliable seal; at the same time, the up and down clamping method also facilitates the connection between the air hole on the fixture and the upper part of the L-shaped pressure sensor 10. , The lower static pressure holes 8 are aligned and communicated to reduce the installation time. The clamping is more convenient and fast, and the seali...

Embodiment 2

[0021] A novel L-shaped pressure receptor 10 fixture includes an upper casing 6 and a lower casing 12 for fixing the L-shaped pressure receptor 10, and one end of the upper casing 6 and the lower casing 12 is connected with the main body 5 at the same time. Connected, the main body 5 is provided with a sealing ring 4, the main body 5 is provided with a tightening handwheel 3 and a compression sleeve 2, and one end of the main body 5 is provided with a total pressure pipe joint 1.

[0022] Both the upper shell 6 and the lower shell 12 are provided with a static pressure nozzle 7 , and the other end of the static pressure nozzle 7 communicates with the static pressure hole 8 . An upper gasket 9 is arranged between the upper casing 6 and the L-shaped pressure receptor 10 ; a lower gasket 11 is arranged between the lower casing 12 and the L-shaped pressure receptor 10 .

[0023] The static pressure holes 8 are located on the L-shaped pressure receptor 10 and are aligned with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com