Straight-joint type spindle running-in testbed

A direct-connection and test bench technology, which is applied in the testing of machines/structural components, mechanical components, machine gears/transmission mechanisms, etc., can solve the problem of affecting the production efficiency of equipment and the inability to detect the dynamic accuracy of direct-connected spindles, etc. problems, to achieve the effect of improving service life and reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

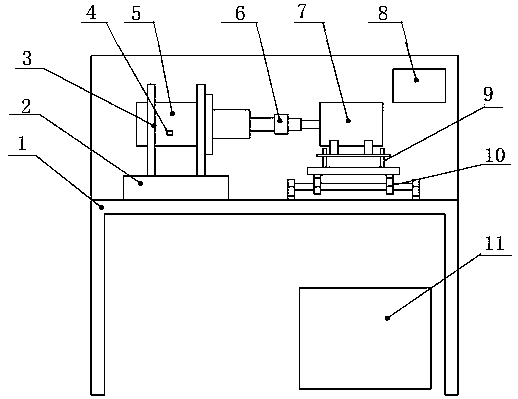

[0011] Referring to the accompanying drawings, a direct-connected spindle running-in test bench includes a platform 1, a support base 2, a clamping block 3, a vibration sensor 4, a direct-connected spindle 5, a coupling 6, a drive motor 7, a lubrication device 8, The drive motor lifting adjustment device 9, the drive motor front and rear adjustment device 10, and the control system 11 use bolts to fix the support base 2 on the platform 1. The knotted spindle 5 is precisely positioned, the fastening bolts are clamped and fixed, and the vibration sensor 4 is installed at the bearing position of the direct-coupled spindle 5 to monitor the vibration of the running bearing, and the front and rear adjustment devices 10 of the driving motor are fixed on the platform with bolts 1, ensure that the central axis of the driving motor front and rear adjustment device 10 is on the same straight line as the central axis of the support seat 2, install the driving motor lifting adjustment devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com