Control method of cold heading steel flocculent flow

A technology of cold heading steel flocculation and control method, which is applied in the field of cold heading steel, can solve problems such as cold heading steel cracking, and achieve the effects of improving quality, reducing cost, and speeding up development progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the specific implementation process, the control method of cold heading steel ML08AL flocculation of the present invention, its production process route is:

[0034] Mixed iron furnace→Molten iron pretreatment (desulfurization, slag removal)→120-ton top-bottom combined blowing converter→Molten steel pre-deoxidation→120-ton LF furnace refining→150mm×150mm billet continuous casting.

[0035] The control method of cold heading steel ML08AL flocculation of the present invention is as follows:

[0036] 1. Calcium treatment of cold heading steel and denaturation theory of inclusions

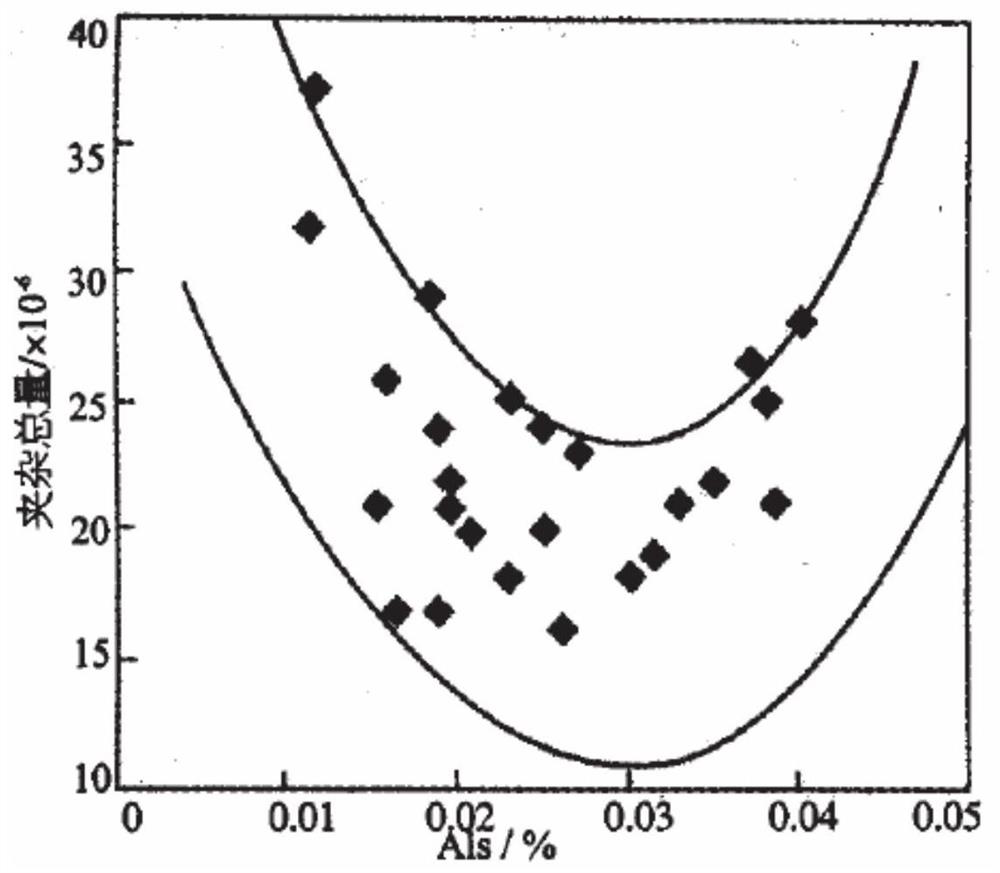

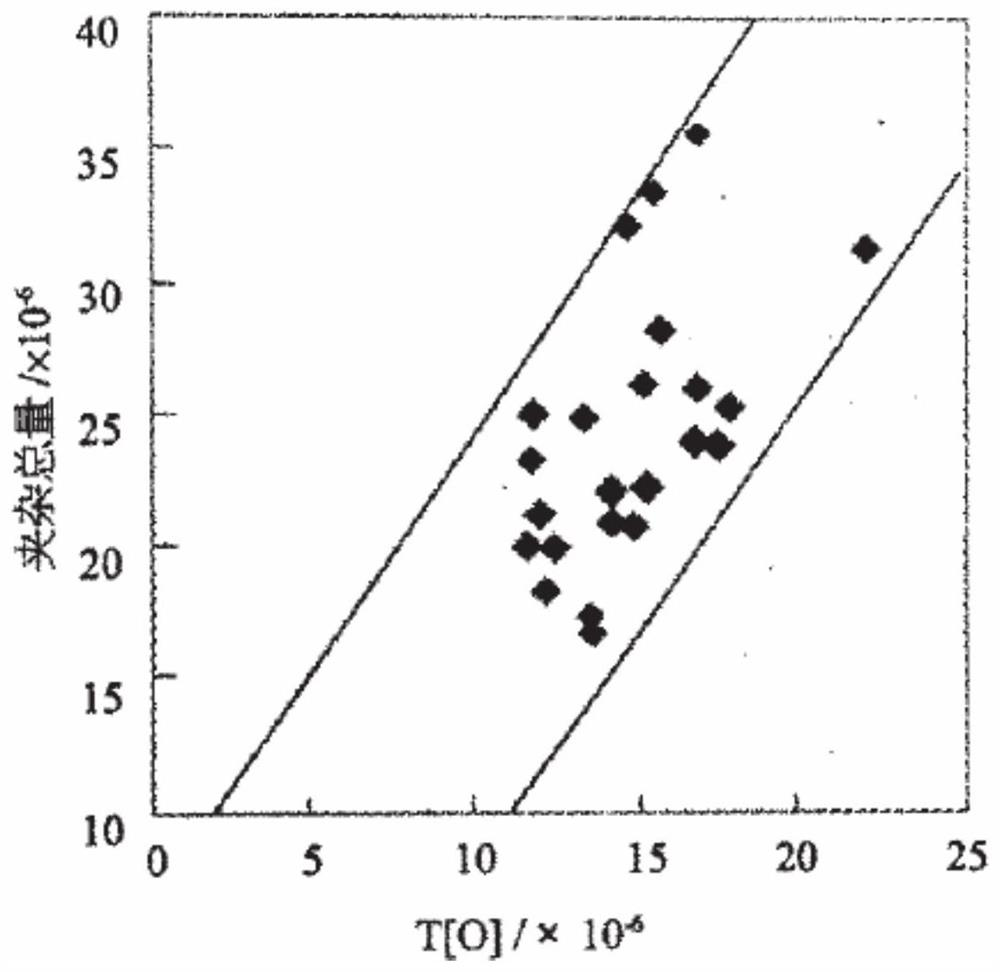

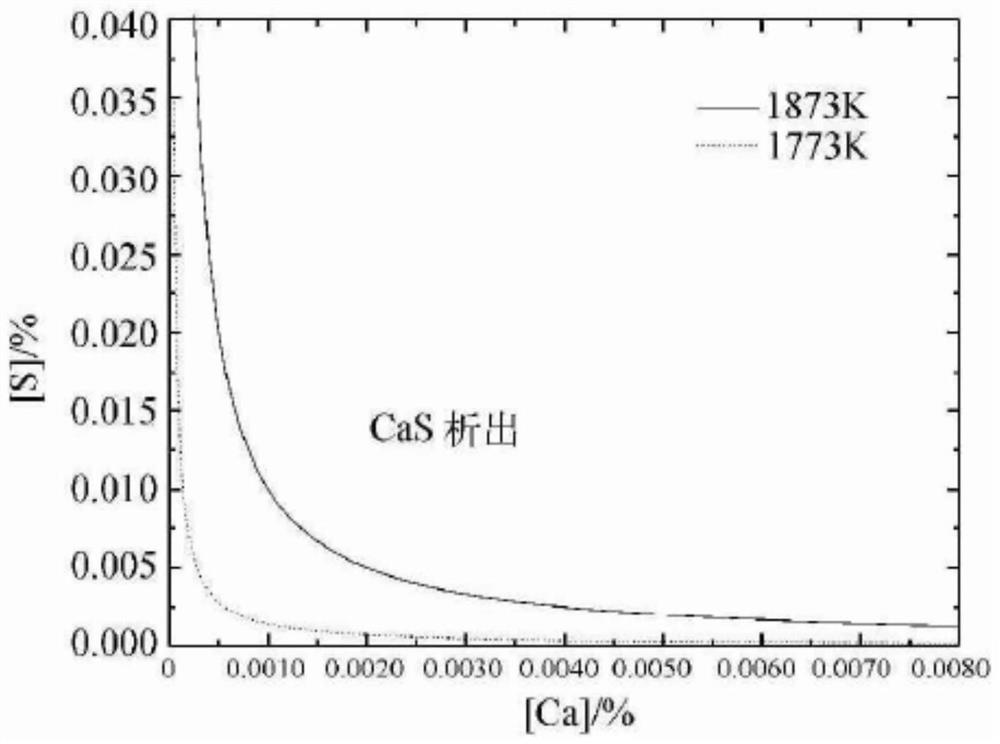

[0037] Regarding the control of the morphology and composition of inclusions in cold heading steel, experts at home and abroad have shown that: when the aluminum deoxidation product is transformed into 12CaO·7Al by calcium treatment 2 o 3 At the same time, because its melting point is only 1455°C, it is easy to float up and be absorbed into the slag. When performing calcium treatment, theore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com