Preparation method of beta-alanine

A technology of alanine and aspartic acid, applied in the biological field, can solve the problems of poor enzyme stability and low enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention provides a method for preparing beta-alanine, comprising: preparing a beta-alanine product from a reactant containing fumaric acid and ammonia water in the presence of a catalyst, wherein the catalyst comprises aspartic acid A catalytic composition of enzyme and L-aspartate-alpha-decarboxylase, and fumaric acid is added during the reaction, and the total amount of moles of fumaric acid added is equal to the initial molar amount of ammonia water in the reactant Subtract the initial molar amount of fumaric acid in the reactants.

[0020] The "initial molar amount" of fumaric acid or ammonia water refers to the initial molar amount of fumaric acid or ammonia water before the catalytic reaction begins. The "initial fumaric acid" weight in the reactants refers to the initial weight of fumaric acid added to the reactants prior to the start of the catalytic reaction. In certain embodiments, in the reactant, the initial molar ratio of the ammonia water to...

Embodiment 1

[0062] Fermentation culture of Escherichia coli engineering bacteria, inorganic salt fermentation medium formula: NaCl 1g / L; MgSO 4 -7H 2 O 1g / L; FeSO 4 -7H 2 O 0.02g / L; ZnSO 4 -7H 2 O 0.03g / L; CuSO 4 -5H 2 O 0.005g / L; (NH 4 ) 2 SO 4 4g / L; KH 2 PO 4 4g / L, sterilized at 121°C for 15 minutes, cooled to 37°C after sterilization, inoculated with 2% inoculum, fermented at 37°C, dissolved oxygen maintained at 30%-50%, ventilation volume 1VVM, Add ammonia water to adjust pH and provide nitrogen source, ammonia water to control pH at 7.5, feed glucose to provide carbon source, control residual sugar to 0.1-0.5g / L, and cultivate to OD 600 When = 30, the temperature was lowered to 30 °C and IPTG was added for induction, and the fermentation was terminated after 30 hours of induction and culture. 600 It reached about 110, and the wet weight of the cells after centrifugation reached about 120 g / L.

Embodiment 2

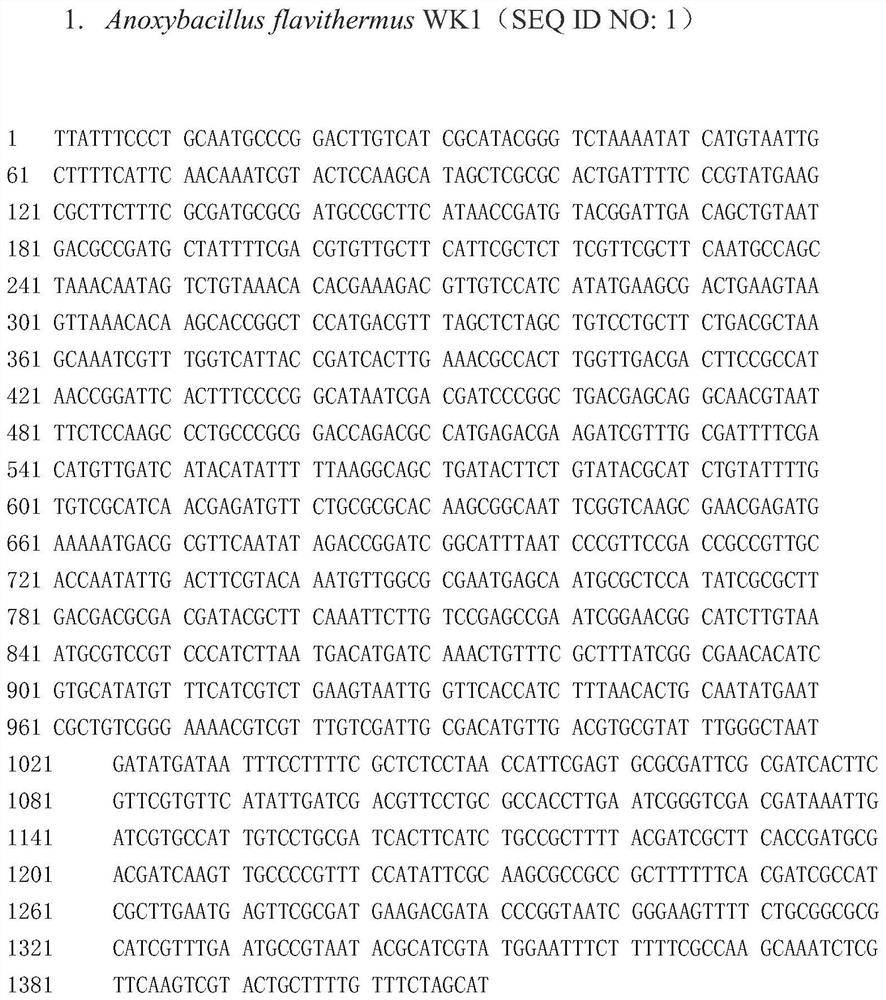

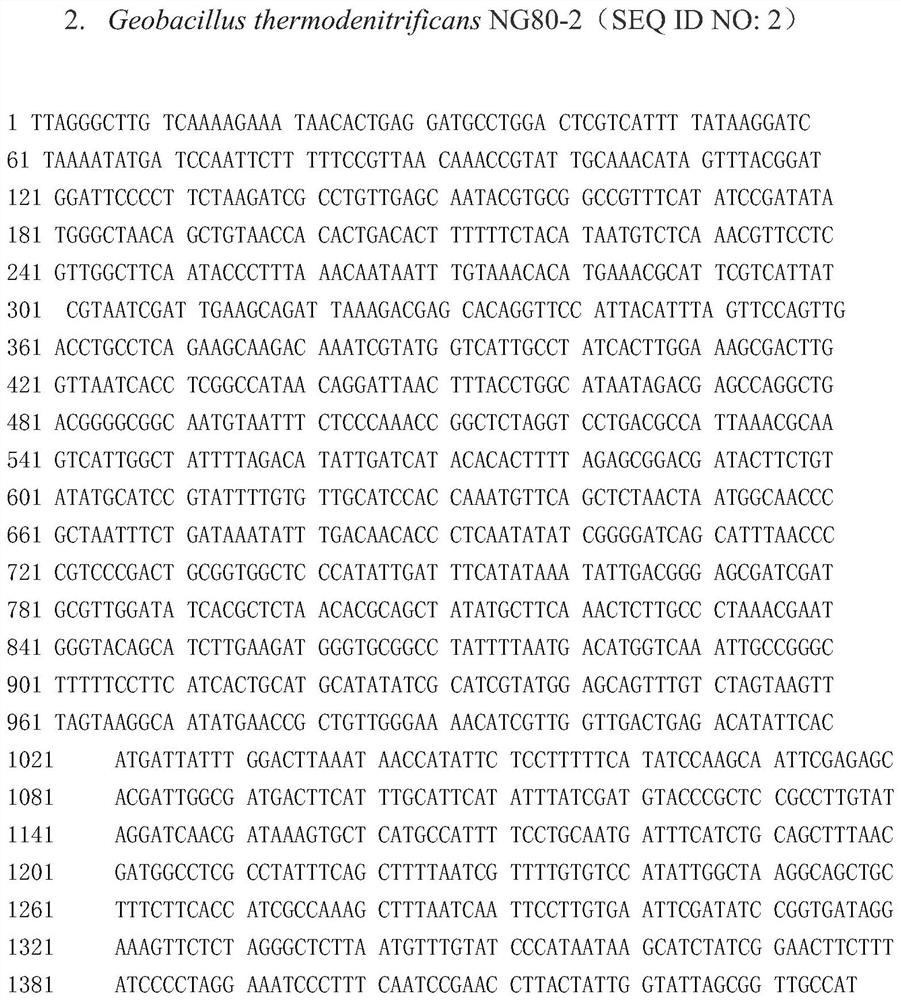

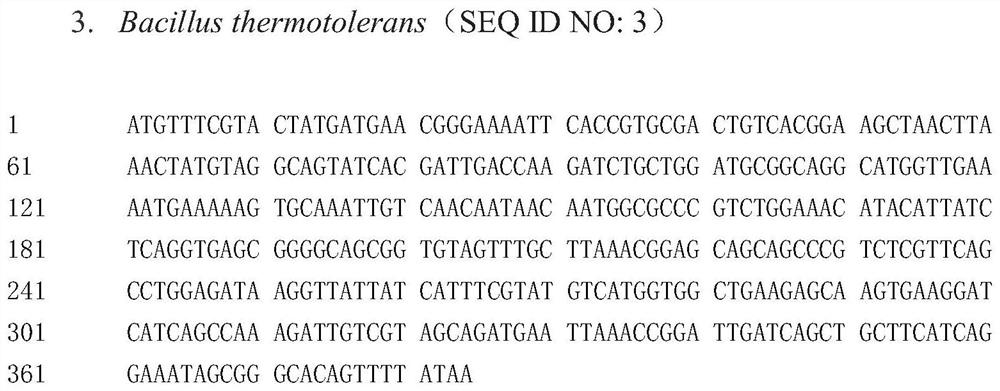

[0064] With reference to "Molecular Cloning Experiment Guide (3rd Edition)" (Science Press) and Li Y.et.al.Appl.Microbiol.Biotechnol.2017, 101, 6015-6021, the aspartic acid containing aspartic acid derived from Anoxybacillus flavithermus WK1 was prepared Escherichia coli engineering bacteria with acid enzyme (hereinafter referred to as "enzyme 1") and Escherichia coli engineering bacteria strains containing L-aspartate-α-decarboxylase (hereinafter referred to as "enzyme 2") derived from Bacillus thermotolerans, conventional LB The culture medium is fermented by the method of Example 1 and then centrifuged (rotating speed 5000 rpm, centrifugation time 5 min) to obtain wet Escherichia coli engineering bacteria for use.

[0065]Prepare 3L ammonium fumarate solution (100g fumaric acid / L), the initial molar amount of fumaric acid is 2.586mol, the initial molar amount of ammonia water is 5.172mol, add 3g E. coli engineering containing enzyme 1 derived from Anoxybacillus flavithermus ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com