Yttrium-based oil-soluble high-temperature vanadium inhibitor and preparation method thereof

A vanadium inhibitor and base oil technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of moisture-absorbing skinning, uneven mixing, inconvenient use, etc., to avoid side effects, uniform dispersion, The effect of improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a preparation method of an yttrium-based oil-soluble high-temperature vanadium inhibitor, comprising the following steps:

[0025] 1) Mix 50-90 parts of sulfonic acid, 10-30 parts of base oil, 200-1000 parts of solvent, 5-20 parts of methanol and 30-50 parts of yttrium oxide, and carry out acid-base reaction for more than 15 minutes;

[0026] 2) Add 5-20 parts of water and 5-20 parts of ammonia water to the product obtained in step 1) and pass CO 2 The reaction is carried out, and CO 2 After 20-60 minutes, add 5-20 parts of water and 5-20 parts of ammonia water again, continue the reaction for 30-60 minutes, and filter to obtain the yttrium-based oil-soluble high-temperature vanadium inhibitor.

[0027] During specific implementation, in step 1), the sulfonic acid can be selected from at least one of petroleum sulfonic acid, synthetic sulfonic acid, alkylbenzenesulfonic acid and alkylnaphthalenesulfonic acid, and is preferably petroleum sulfonic...

Embodiment 1

[0032] Accurately weigh 50g of C18 benzenesulfonic acid, base oil (its kinematic viscosity at 40°C is 50mm 2 / s) 15g, 300g of diesel oil, 35g of yttrium oxide, and 8g of methanol were placed in a four-neck flask, preheated to 40°C and stirred evenly at a stirring speed of 450r / min, and acid-base reaction was carried out at 40°C for 20min. Put 8g of water and 5g of ammonia water into the flask and feed CO2 at a rate of 6L / min. 2 Carry out carbonation reaction, while passing CO 2 After 50 minutes, add 5g of water and 5g of ammonia water again, continue to react for 60min, and filter to obtain the product of yttrium-based oil-soluble high-temperature vanadium inhibitor.

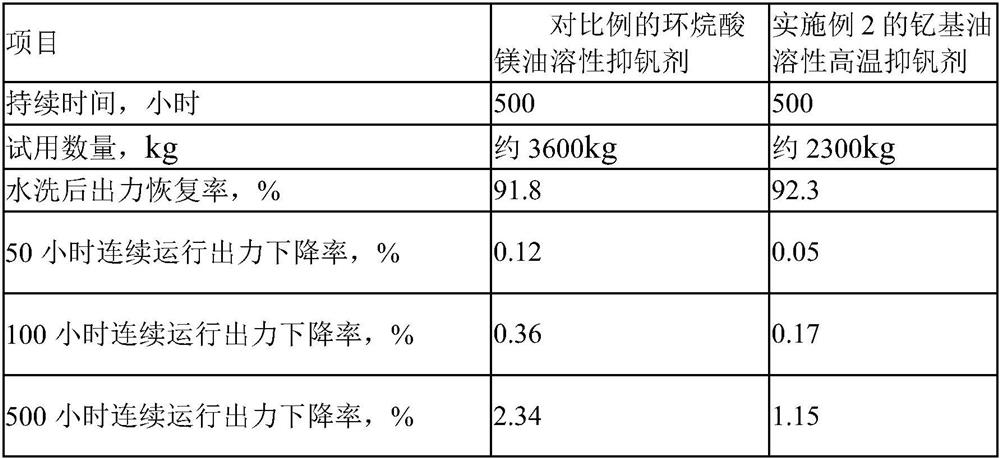

[0033] The product properties of the yttrium-based oil-soluble high-temperature vanadium inhibitor obtained in this embodiment are shown in Table 1 below.

[0034] Table 1

[0035] project analysis results Analytical method Density (20℃, g / cm 3 )

[0036] As can be seen from the data in Tab...

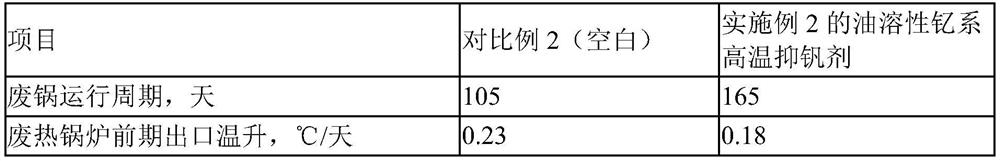

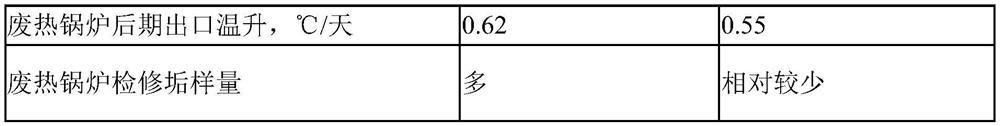

Embodiment 2

[0038] Accurately weigh 90g of petroleum sulfonic acid, base oil (its kinematic viscosity at 40°C is 100mm 2 / s~200mm 2 / s) 30g, 900g of C9 heavy aromatics, 50g of yttrium oxide, and 20g of methanol were placed in a four-neck flask and stirred evenly at a stirring speed of 450r / min, and acid-base reaction was carried out at 50°C for 30min. Put 20g of water and 20g of ammonia water into the flask and feed CO2 at a rate of 12L / min. 2 Carry out carbonation reaction, while passing CO 2 After 45 minutes, add 20g of water and 20g of ammonia water again, continue to react for 60min, and filter to obtain the product of yttrium-based oil-soluble high-temperature vanadium inhibitor.

[0039] The product properties of the yttrium-based oil-soluble high-temperature vanadium inhibitor obtained in this embodiment are shown in Table 2 below.

[0040] Table 2

[0041] project analysis results Analytical method Density (20℃, g / cm 3 )

[0042] As can be seen from the dat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com