Nuclear pore film automatic production device adaptive to beam flow, and method

A technology for automatic production and nuclear pore membranes, applied in chemical instruments and methods, applications, membrane technology, etc., can solve problems such as uneven irradiation and high defect rate, achieve uniform irradiation membranes, improve product qualification rate, and stabilize The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

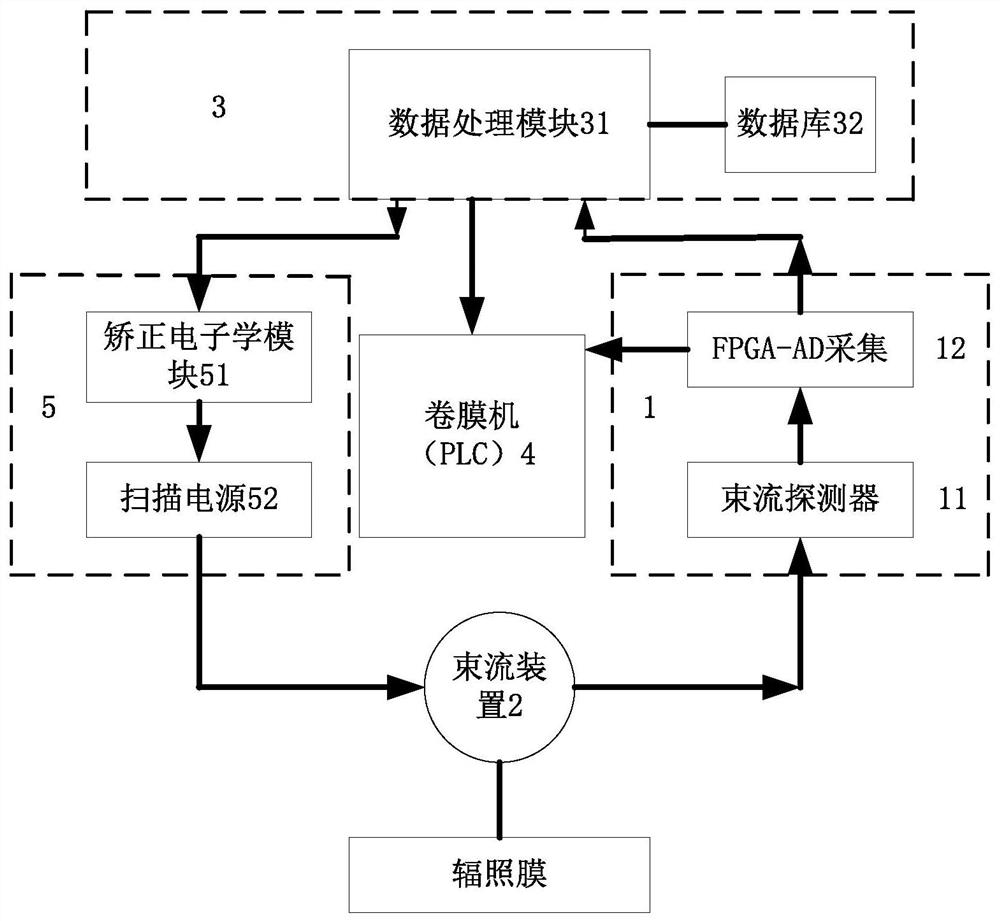

[0050] Such as figure 1 As shown, the self-adaptive beam current nuclear pore membrane automatic production device provided by this embodiment includes a data detection system 1, a beam current device 2, a control computer 3, and a film winding machine 4;

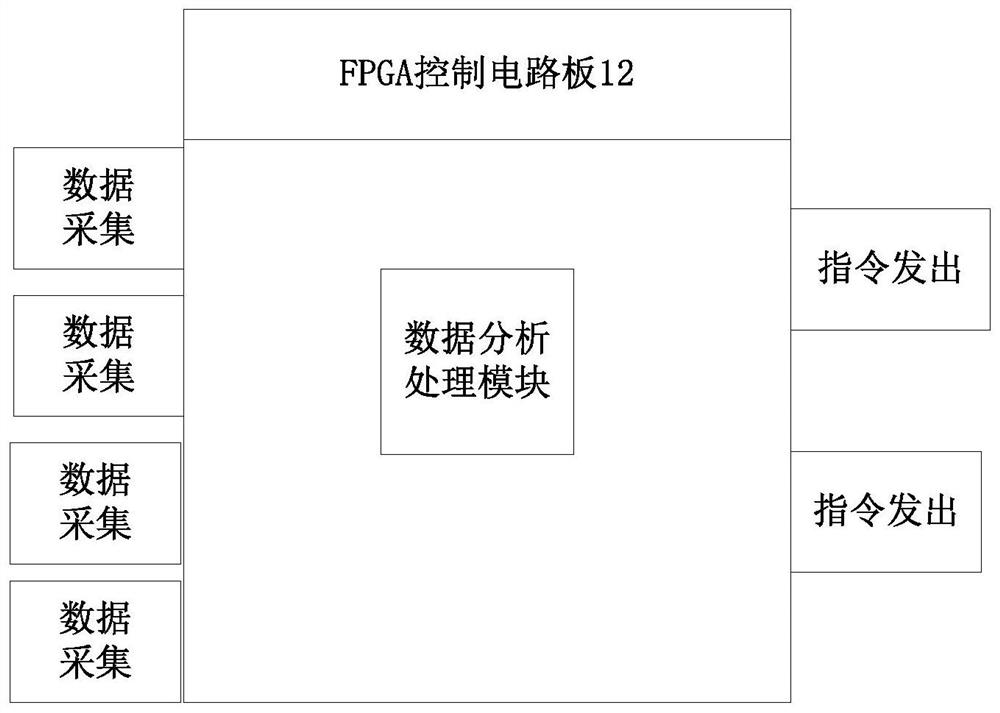

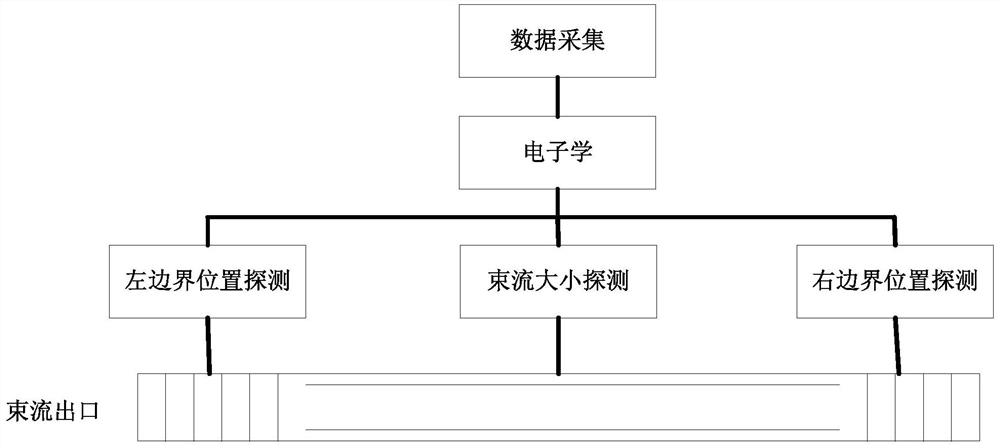

[0051] The data detection system 1 includes a number of beam detectors 11 and a beam collection system 12; the beam detector 11 is used for online real-time detection of the beam size and position emitted by the beam device 2, and the beam collection system 12 is used for collecting the beam detector 11 beam signal;

[0052] The control computer 3 is used to obtain the data of the beam collection system 12 for fitting and send instructions to the film winding machine 4 so that the rotation speed of the film winding machine 4 matches the beam current size, so that the nuclear pore film production is always in the optimal state. Among them, the optimal state means that the production efficiency of the nuclear pore membrane is at t...

Embodiment 2

[0064] This embodiment details the automatic production method of an adaptive beam current nuclear pore membrane, which includes the following steps:

[0065] S1. The components of the production equipment are ready for normal production;

[0066] S2. During the production process, the beam detector 11 detects the beam current intensity and position signals emitted by the beam device;

[0067] S3. The beam current acquisition system 12 collects beam detector data and sends it to the control computer 3;

[0068] S4. The control computer 3 receives the beam current acquisition system data, performs fitting analysis and calculation, and controls the film winding machine 4 so that the rotating speed of the film winding machine 4 matches the beam current size to ensure that the nuclear pore film production is always in the expected state .

[0069] Further, the method also includes a step for correcting the magnitude of the current and the magnitude of the frequency output by the beam curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com