Magnesium-chromium refractory mortar production equipment and method thereof

A technology for refractory mud and production equipment, applied in chemical instruments and methods, dissolving, grain processing, etc., can solve the problem of inconvenient control of the discharge speed of the discharge pipe, and achieve the effect of preventing accumulation and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

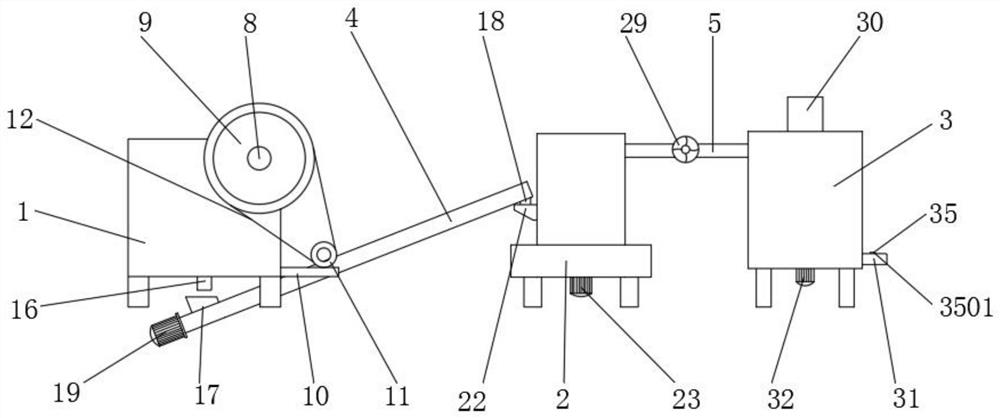

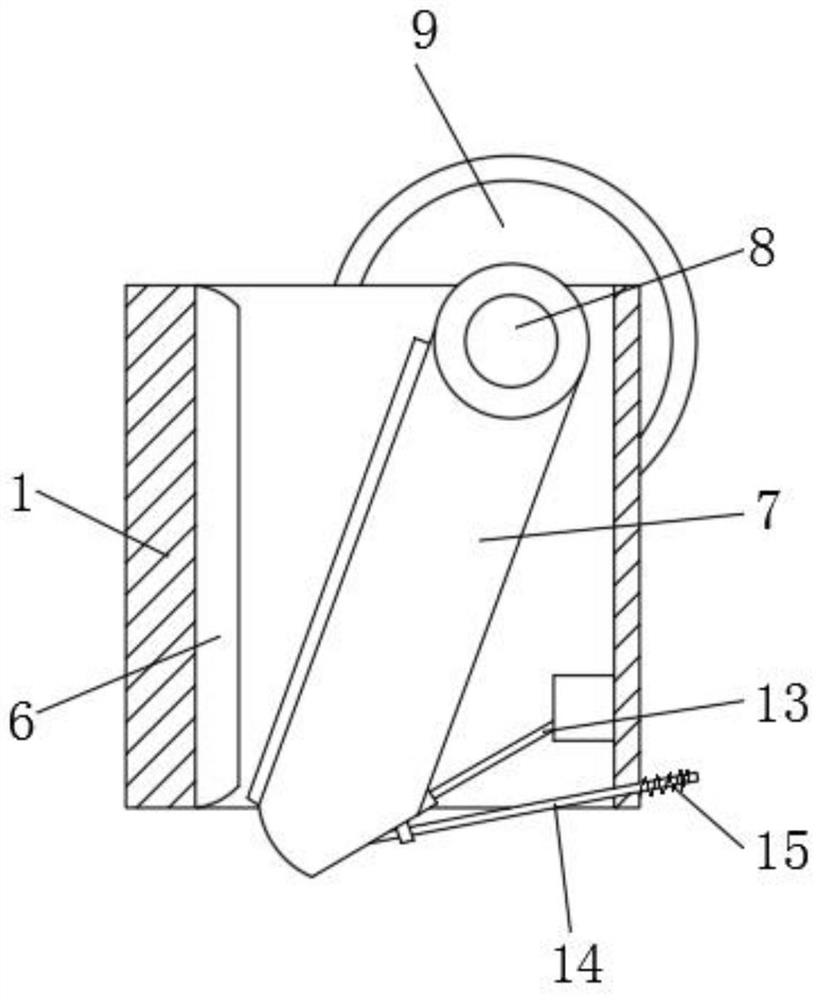

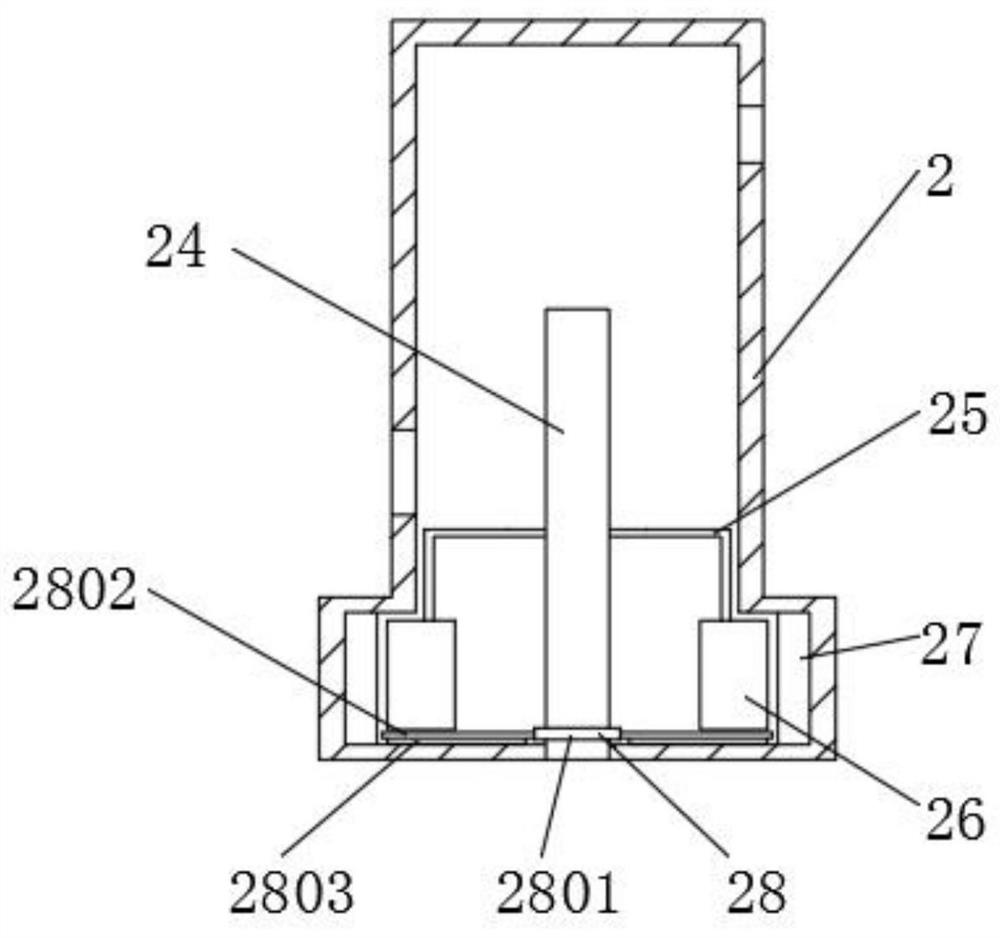

[0033] Such as Figure 1-6As shown, the present invention relates to a magnesia-chrome refractory mud production equipment, comprising a crushing box 1, a milling box 2 and a stirring box 3, the crushing box 1 and the stirring box 3 are respectively located on both sides of the milling box 2, and the crushing box 1 and the milling box 2 are provided with a conveying cylinder 4, and between the milling box 2 and the stirring box 3 is connected an exhaust pipe 5, and the interior of the crushing box 1 is fixedly installed with a static jaw plate 6 near one side, and crushing The inside of the box 1 is equipped with a movable jaw plate 7 near the other side, the top of the movable jaw plate 7 is connected with an eccentric shaft 8, the end of the eccentric shaft 8 is connected with a pulley 9, and the bottom of the crushing box 1 is fixedly installed with a support plate 10, the upper surface of the support plate 10 is supported by a drive motor 11, a transmission belt 12 is conn...

Embodiment 2

[0036] On the basis of embodiment 1, a kind of using method of magnesia-chrome refractory mud production equipment comprises the following steps:

[0037] S1: Start the drive motor 11, the drive motor 11 drives the pulley 9 to rotate through the transmission belt 12, the pulley 9 rotates and the eccentric shaft 8 rotates accordingly, the movable jaw plate 7 moves relative to the crushing box 1 through the connecting rod 14 and spring 15, and the crushing box 1 starts To work, put the chrome sand that needs to be broken into the inside of the crushing box 1, and the movable jaw plate 7 cooperates with the static jaw plate 6 to squeeze and crush the chrome sand, so that the large piece of chrome sand raw material can be broken into small pieces of chrome sand;

[0038] S2: The crushed small pieces of chrome sand fall into the conveying cylinder 4 through the falling hopper 16 and the feeding hopper 17, start the No. 1 motor 19, and the No. 1 motor 19 drives the conveying rod 20 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com