Self-moving material balance filtering device, extraction kettle comprising same and use method

A filtration device and material balance technology, applied in filtration separation, solvent extraction, separation methods and other directions, can solve the problems of uneven extraction of raw materials, reduced product recovery rate, low bulk density, etc., to improve the extraction product recovery rate and improve product quality Recovery rate, the effect of increasing the filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

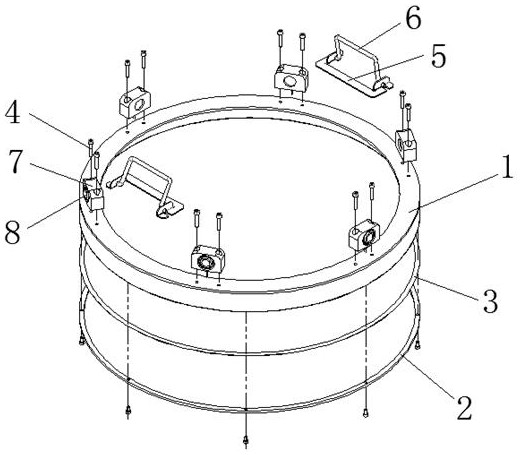

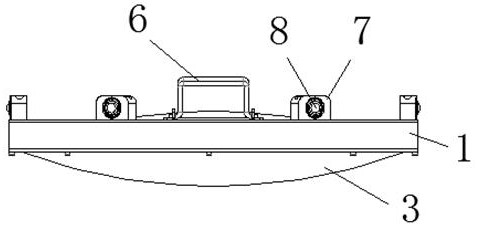

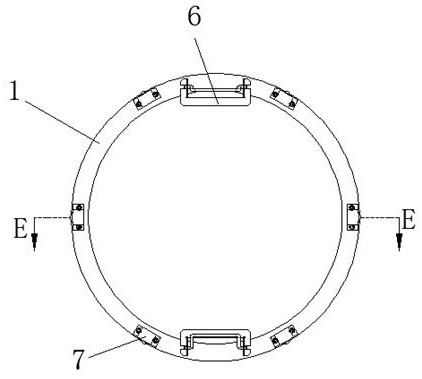

[0035] see Figure 1-4 , a self-moving material balance filter device, used for supercritical fluid extraction devices, including a ring mount 1 and a pressure ring 2 below the ring mount 1, and a filter is arranged between the ring mount 1 and the pressure ring 2 The cloth 3, the ring mounting seat 1, the filter cloth 3 and the pressure ring 2 are detachably connected by bolts 4, and the upper surface of the ring mounting seat 1 is also provided with a handle 6 assembly. The handle 6 assembly includes a bracket 5 and a handle 6 arranged on the bracket 5, and is used for putting the self-moving material balance filter into the extraction basket or taking it out from the extraction basket.

[0036] The upper surface of the ring mount 1 is evenly provided with several ball mounts 7 along the circumference, the ball mount 7 and the ring mount 1 are connected by bolts 4, and a card slot is provided in it, and an elastic socket is provided in the card slot. Ball assembly 8.

[00...

Embodiment 2

[0041] see Figure 1-7 , an extraction kettle containing a self-moving material balance filter device, including a kettle cover 9, a kettle body 10 with an extraction chamber 11 and a distributor located at the bottom of the kettle body 10 from top to bottom, and the kettle body 10 is also provided with Locking mechanism 12, and it is connected with the kettle lid 9 through the locking mechanism 12. There are at least two extraction baskets 13 (specifically 2 in this embodiment) in the extraction chamber 11 from top to bottom, and two adjacent extraction baskets 13 The material baskets 13 are connected by bolts 4, and the top of the extraction material basket 13 is provided with a material basket cover containing a filter screen or a filter plate, and the kettle body 10 is also provided with a feed port 14 communicating with the extraction chamber 11 , carbon dioxide inlet 15, carbon dioxide outlet 16 and safety device interface 17.

[0042] The outer wall of the kettle body ...

Embodiment 3

[0055] The method for using the extraction kettle containing the self-moving material balance filtering device comprises the following steps:

[0056] 1) Open the top of the extraction basket 13, which contains the filter screen or the filter plate, pour the material into the extraction basket 13 from the mouth of the basket, and then place the self-moving material balance filter device 23 on the top of the material. Good material basket cover; Put extraction material basket 13 in the extraction kettle, and cover still lid 9 well.

[0057] 2) Open the carbon dioxide inlet pipe 27, so that the carbon dioxide is evenly distributed into the extraction chamber through the circulation pipe 26 and the distribution holes of the distributor to extract the materials in the extraction basket 13;

[0058] 3) During the material extraction process, the self-moving material balance filter device 23 moves up and down in the extraction basket 13 under the rolling of the large ball 81. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com