Device and method for testing friction sensitivity of explosives and powders

A friction sensitivity and testing device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problem of inability to directly judge the safety of the production and processing process, the difficulty of strict control of sample position and thickness, and the establishment of practical connections for friction sensitivity, etc. problems, to achieve the effect of simple and reliable analysis of test results, simplified loading operation process, consistent speed and force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

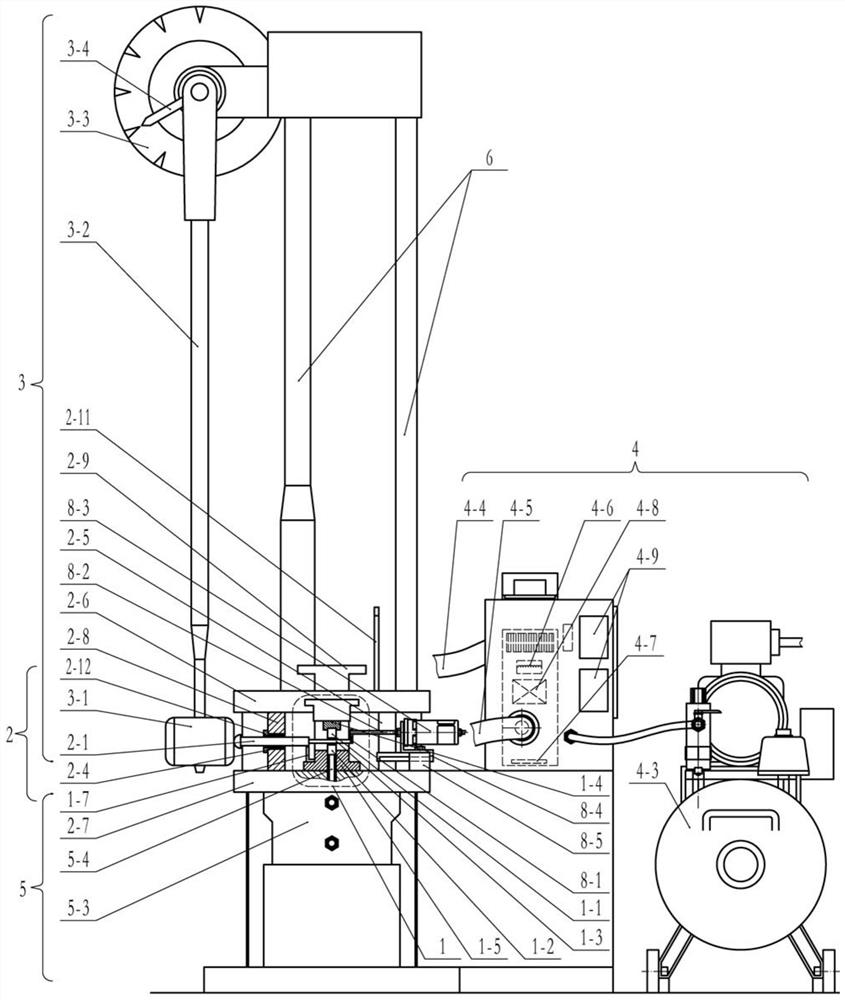

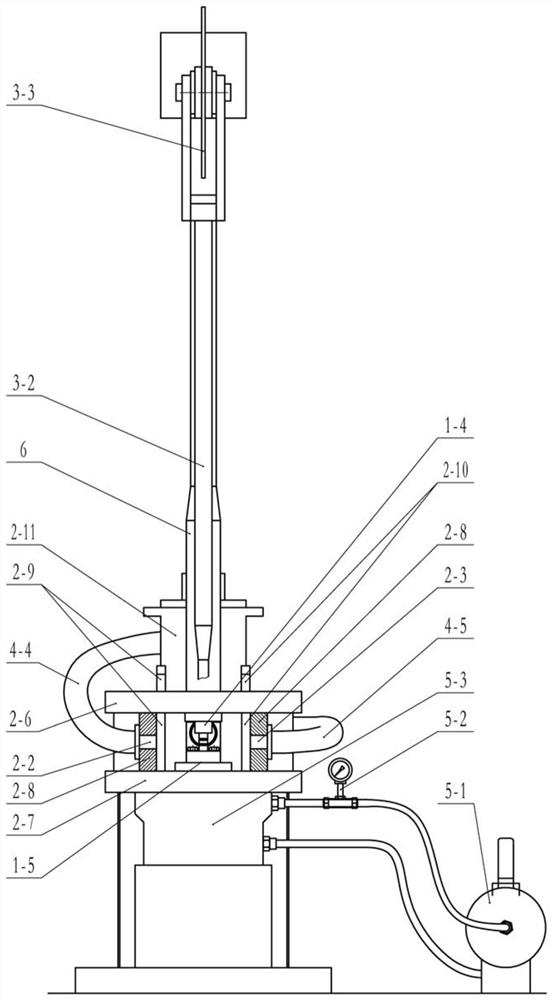

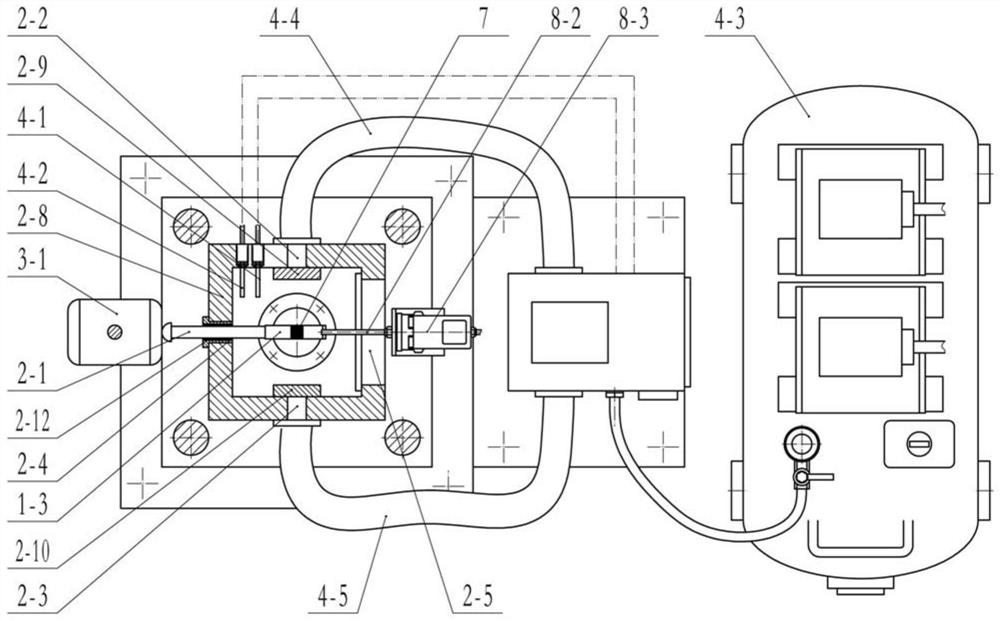

[0051] Such as Figure 1~5 As shown, the friction sensitivity testing device of this embodiment includes a sample loading system 1, an explosion chamber 2, a pendulum mechanism 3, a temperature and humidity control system 4, a pressure loading system 5 and a frame 6; wherein the sample loading system includes an upper top Column 1-1, lower top column 1-2, sliding piece 1-3, uploading platform 1-4 and downloading platform 1-5; explosion chamber 2 includes driving rod 2-1, air inlet 2-2, and air outlet 2- 3. Pendulum impact port 2-4, slider moving port 2-5, upper support plate 2-6, lower support plate 2-7, chamber wall 2-8, air inlet protective plate 2-9, air outlet protective plate 2-10, sliding plate moving port protective plate 2-11; pendulum mechanism 3 includes pendulum 3-1, pendulum bar 3-2, dial 3-3, pendulum angle indicator needle 3-4, driving lever 3-5 The temperature and humidity control system 4 includes a temperature sensor 4-1, a humidity sensor 4-2, an air compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com