Method and Application of Melting Crystallization to Separation of Dimethyl Carbonate Methanol Azeotrope

A dimethyl carbonate, melting and crystallization technology, applied in the chemical industry, to achieve low operating costs, high product purity, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

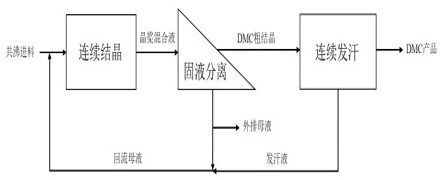

[0028] DMC methanol azeotropic composition, in which the DMC content is 33wt%, and the methanol content is 67wt%. It is passed into a continuous melting crystallizer, and the operating temperature in the crystallizer is controlled at -55 to -60°C. DMC is precipitated in the form of crystals, and in the crystallization system Suspension growth, where the continuous melting crystallizer can use a scraper type or a conventional kettle type cooling crystallizer, such as MSMPR type or DTB type crystallizer, in order to keep the crystallizer wall clean, a scraper can be set between the stirring blade and the crystallizer wall plate or brush. The crystal slurry mixture obtained through continuous crystallization enters the solid-liquid separator for solid-liquid separation to obtain DMC crude crystals and crystallization mother liquor. After this step of separation, the purity of DMC crude crystals can generally reach 97%-99%. The DMC content in the crystallization mother liquor is ...

Embodiment 2

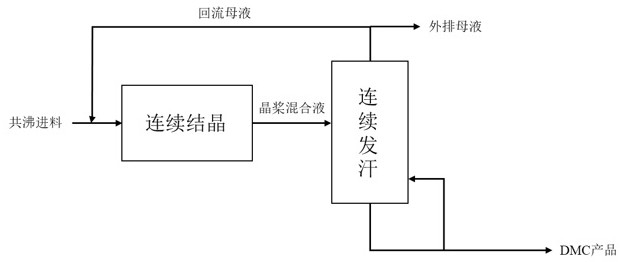

[0030]DMC methanol azeotropic composition, in which DMC content is 35wt%, methanol content is 63wt%, and other organic impurities are 2%. It is passed into a continuous melting crystallizer, and the operating temperature in the crystallizer is controlled at -50 to -55°C. DMC is precipitated in the form of crystals. And it grows in suspension in the crystallization system. Here, the continuous melting crystallizer can adopt a scraper type or a conventional tank type cooling crystallizer, such as the MSMPR type or DTB type crystallizer. In order to keep the crystallizer wall clean, the stirring blade and the Scrapers or brushes are arranged between the walls of the crystallizer. The crystalline slurry mixture obtained through continuous crystallization directly enters the continuous liquid phase sweating section, where the sweating device can use a gravity washing tower, a mechanical washing tower or a hydraulic washing tower, and the corresponding solid phase DMC crystals are ma...

Embodiment 3

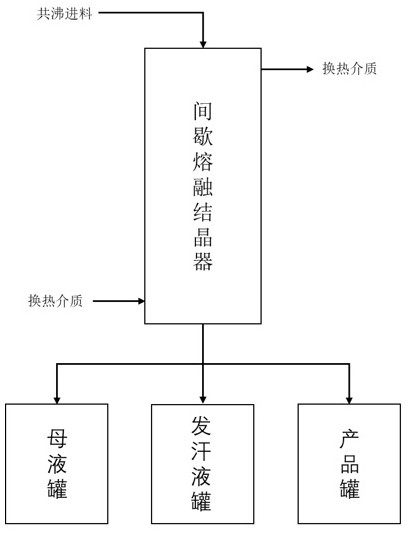

[0032] DMC methanol azeotropic composition, in which the DMC content is 30wt%, and the methanol content is 70wt%, which is passed into the intermittent melting crystallizer. Downward flow reduces boundary layer thickness and optimizes heat and mass transfer efficiency. Pass in cooling medium, first reduce the temperature of the feed liquid to -20°C, then control the cooling rate to 2-4°C / h, continue to cool the crystallization system to -50 to -55°C, and maintain a constant temperature for 2-3h. During this process, DMC is precipitated from the feed liquid in the form of layered crystals, and a DMC crystal layer is formed on the heat exchange wall. Drain the crystallization mother liquor to the mother liquor tank, switch the heat exchange medium, control the temperature of the heat exchange wall to 2-4°C, make the DMC crystal layer partially melt for sweating and purification, control the sweating liquid ratio to 4-6% of the crystal layer mass, put The sweating liquid is disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com