A kind of preparation method of ceramic slate and ceramic slate

A slate and ceramic technology, applied in the production of ceramic materials, etc., can solve the problems of inability to meet the requirements of large-scale home decoration, drying cracked bricks, many cracked bricks in transportation, low drying qualification rate, etc., to improve the processability and internal uniformity. High performance and less stress build-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

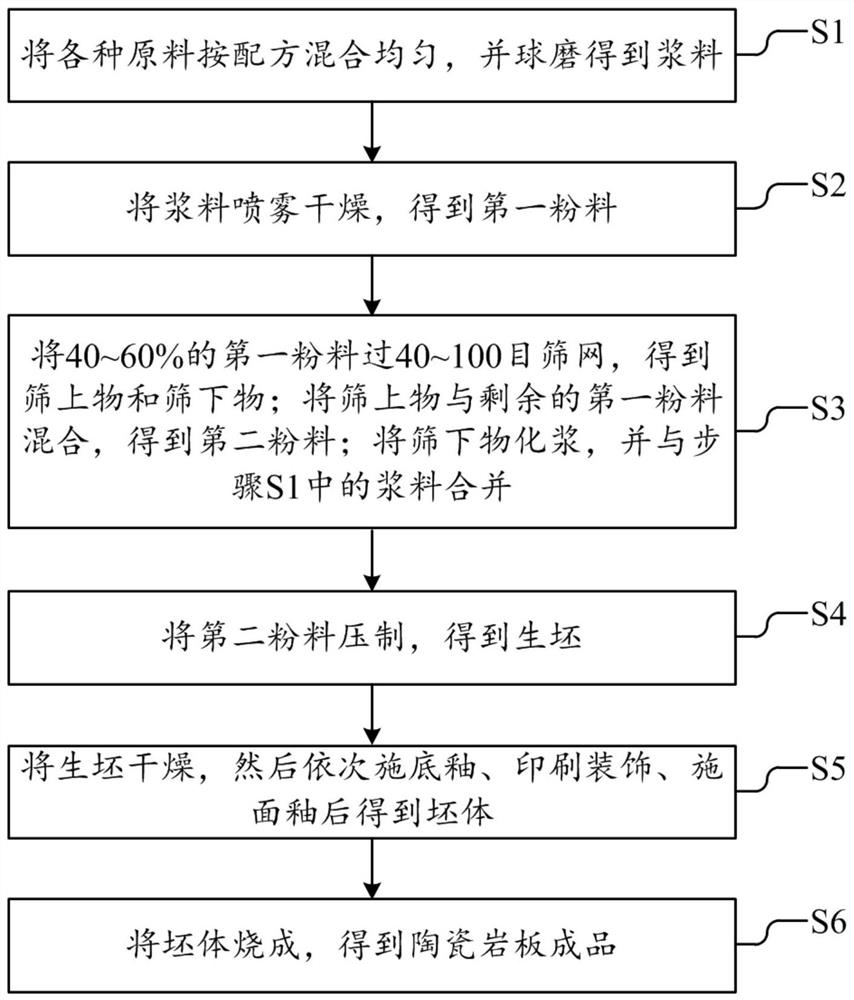

[0046] see figure 1 , the invention provides a kind of preparation method of ceramic slate, which comprises the following steps:

[0047]S1: Mix various raw materials uniformly according to the formula, and ball-mill to obtain slurry;

[0048] Specifically, the formula is:

[0049] 15-20 parts of potassium feldspar, 8-15 parts of albite, 15-20 parts of calcined kaolin, 12-20 parts of black mud, 8-15 parts of white mud, 15-20 parts of pyrophyllite, 1-10 parts of toughening agent ; The sum of the parts by weight of the above raw materials is 100 parts.

[0050] Among them, potassium feldspar and albite are the main fluxes, which can promote sintering, obtain finished ceramic slate with water absorption <0.1%, improve the flexural strength of ceramic slate, reduce micropores, and improve stain resistance. Wherein, the consumption of potassium feldspar is 15-20 parts, and the consumption of albite is 8-15 parts; preferably, the consumption of potassium feldspar is 17-20 parts, ...

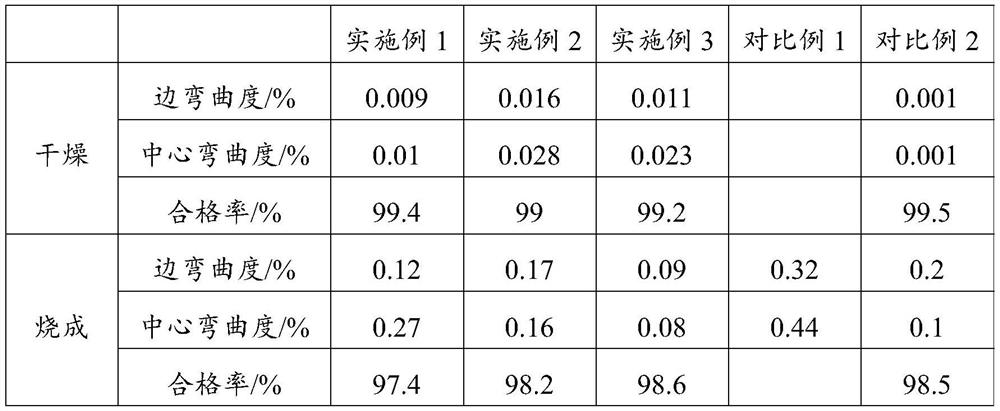

Embodiment 1

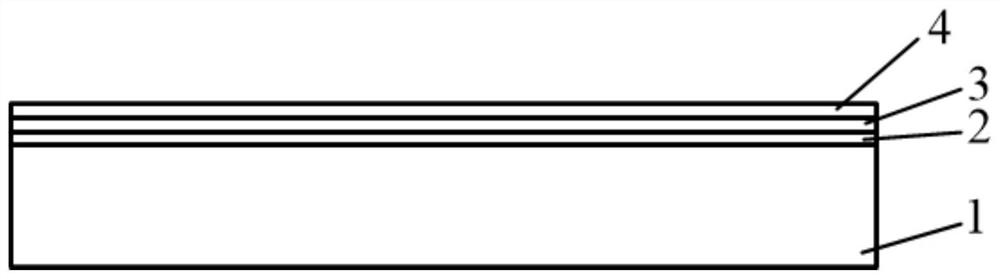

[0090] This embodiment provides a ceramic rock slab with a size of 3600×2000×20mm 3 ; Among them, the thickness of the green layer is 19mm;

[0091] The formulation of the green layer is:

[0092] 19 parts of potassium feldspar, 12 parts of albite, 16 parts of calcined kaolin, 18 parts of black mud, 10 parts of white mud, 18 parts of pyrophyllite, 1 part of low temperature toughening agent, 6 parts of high temperature toughening agent;

[0093] Among them, the particle size of 80% of the calcined kaolin is less than 1 μm; the low temperature toughening agent is methyl cellulose, and the high temperature toughening agent is mullite whisker;

[0094] Preparation method of ceramic slate:

[0095](1) Mixing various raw materials uniformly according to the formula, and ball milling to obtain slurry;

[0096] Among them, the 250-mesh sieve residue of the slurry is 0.2%;

[0097] (2) the slurry is spray-dried, and the first powder is obtained after sieving;

[0098] (3) passing ...

Embodiment 2

[0115] This embodiment provides a large-sized ceramic rock slab with a size of 3600×1800×25mm 3 ; Among them, the thickness of the green body layer is 24.5mm;

[0116] The formulation of the green layer is:

[0117] 19 parts of potassium feldspar, 12 parts of albite, 16 parts of calcined kaolin, 18 parts of black mud, 10 parts of white mud, 18 parts of pyrophyllite, 1 part of low temperature toughening agent, 6 parts of high temperature toughening agent;

[0118] Among them, the particle size of 90% of the calcined kaolin is less than 1 μm; the low temperature toughening agent is tobermorite, and the high temperature toughening agent is talc;

[0119] Preparation method of ceramic slate:

[0120] (1) Mixing various raw materials uniformly according to the formula, and ball milling to obtain slurry;

[0121] Among them, the 250-mesh sieve residue of the slurry is 0.4%;

[0122] (2) the slurry is spray-dried, and the first powder is obtained after sieving;

[0123] (3) pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com