Low-rank coal conveying processing and coal storage system combined use method and device

A low-rank coal and coal storage technology, which is applied in the direction of conveyors, conveyor objects, vibrating conveyors, etc., can solve the problems of increasing the burden on the raw coal processing system, increasing the raw coal cost of the semi-coal plant, and low utilization of coal yards. , to achieve the effect of saving the construction cost of the high platform, saving the processing capacity of the device, and reducing the investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

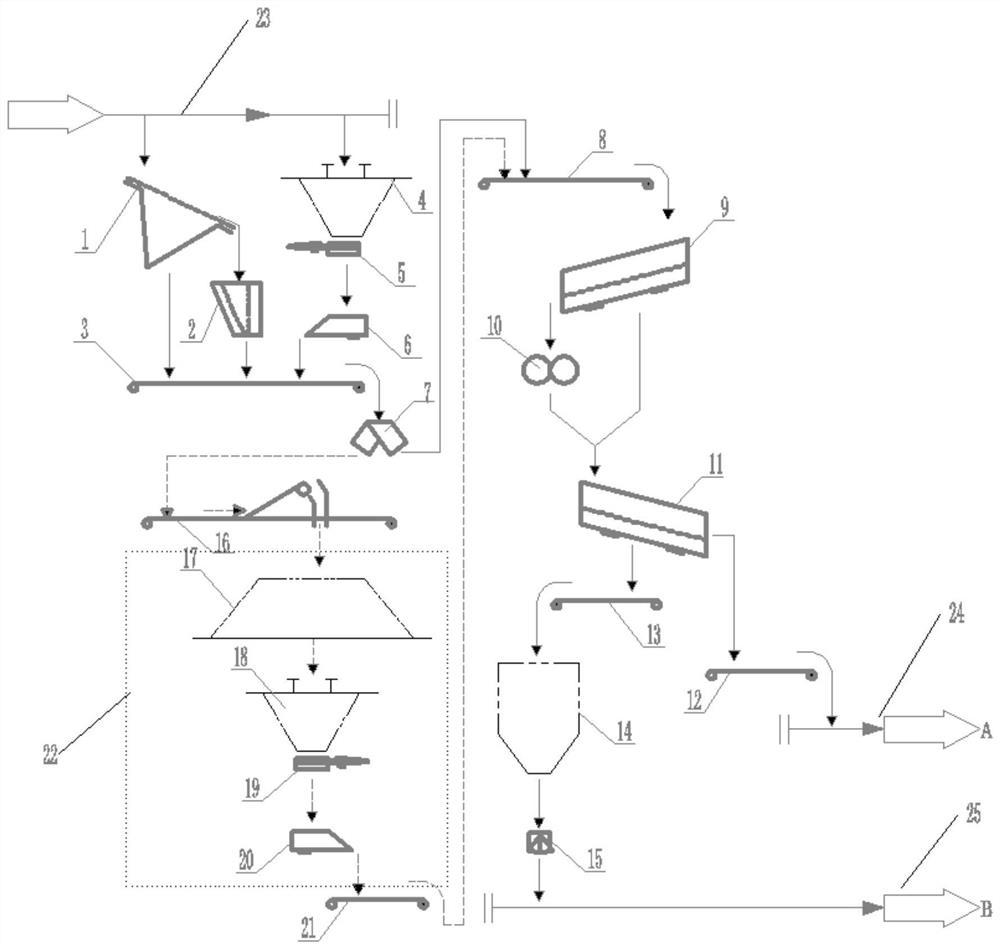

[0029] The present invention combines the direct processing and use of the incoming coal with the storage and use of the incoming coal yard (that is, the combination of the raw coal transportation and processing system and the coal storage system 22), so as to ensure the stable and continuous feeding of the subsequent vertical carbonization furnace to the greatest extent; the coal storage System 22 shares the coarse crushing device, primary screening device, and fine screening and fine crushing system for raw coal transportation and processing, which simplifies the process, reduces investment, and ensures the stability of coal used in the vertical carbonization furnace. A method for combining low-rank coal transportation and processing with a coal storage system, comprising the following specific steps:

[0030] Step 1: When the incoming coal particle size of the car is ≥300mm, it can drive to the high platform 23 and directly unload it on the primary screening device; the prim...

Embodiment 2

[0035] In order to ensure the stable and continuous feeding of the subsequent vertical carbonization furnace to the greatest extent, the process is simplified, the investment is reduced, and the coal consumption of the vertical carbonization furnace is guaranteed at the same time. The present invention provides a combination device for low-rank coal conveying and processing and coal storage system, which includes a raw coal conveying and processing system and a coal storage system 22. The raw coal conveying and processing system includes a coal unloading pit 4, a primary screening device, a first belt Conveyor 3, coarse crushing device arranged below the preliminary screening device, three-way feeder 7, the second belt conveyor 8, the fifth belt conveyor 16, the sixth belt conveyor 21 and fine sieve In the fine crushing system, a first belt conveyor 3 is provided below the discharge port of the primary screening device and the discharge port of the coarse crushing device, and a...

Embodiment 3

[0037] On the basis of Example 1, further, the fine sieve crushing system includes a primary vibrating screen 9, a double-toothed roller crusher 10, a secondary vibrating screen 11, a third belt conveyor 12, and a fourth belt conveyor. Conveyor 13, the tail end of the fourth belt conveyor 13 is provided with a pulverized coal bunker 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com