Piezoelectric film bulk acoustic resonator with high frequency and high coupling coefficient

A technology of bulk acoustic wave resonator and piezoelectric film, which is applied in the direction of electrical components, impedance networks, etc., to achieve the effect of improving coupling coefficient and quality factor, enhancing reliability and heat dissipation performance, and suppressing stray mode effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

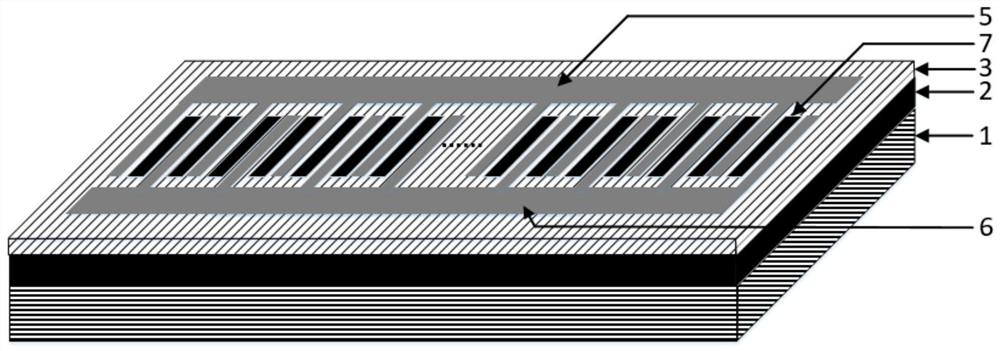

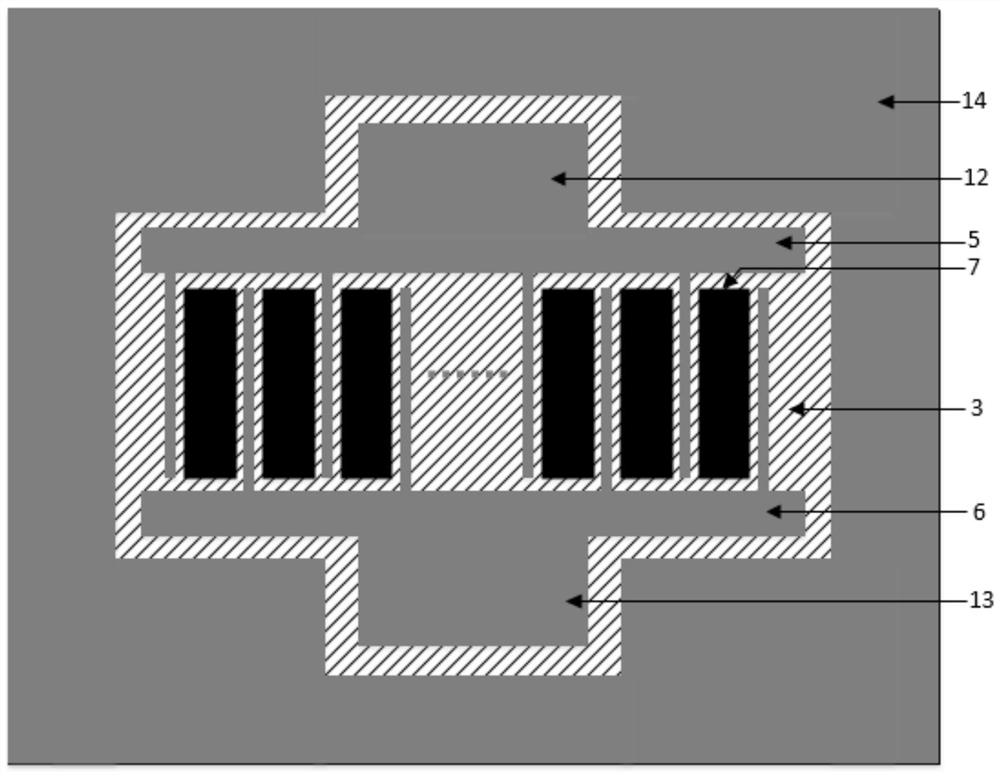

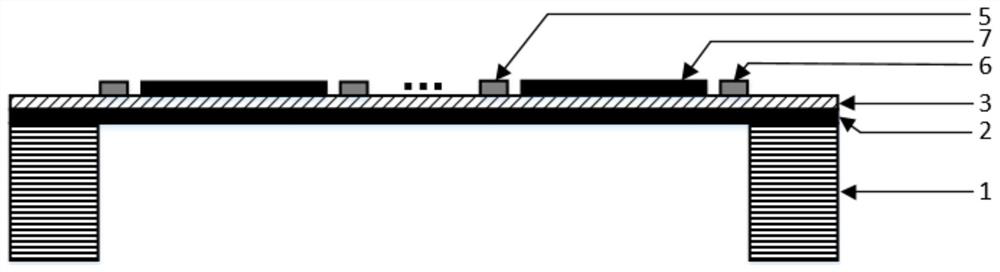

[0042] This embodiment provides a piezoelectric film bulk acoustic resonator with high frequency and high coupling coefficient, the three-dimensional schematic diagram of its structure is as follows figure 1 As shown, top view as figure 2 As shown, the cross-section image 3 shown; including: a silicon-based substrate with insulating silicon dioxide, an interdigital transducer used to excite a transverse electric field, and a suspended free-vibrating piezoelectric thin-film resonator; specifically includes: sequentially stacked from bottom to top A silicon-based substrate 1, a bottom mass loading film 2, a piezoelectric film 3 and an interdigital transducer, wherein the interdigital transducer is formed in mirror-image symmetry of an input electrode 5 and an output electrode 6; the silicon-based substrate 1 Forming a cavity structure by etching;

[0043] The lengths of the electrode fingers of the input electrode 5 and the output electrode 6 are all equal; between the adja...

Embodiment 2

[0055] This embodiment provides a high-frequency high-coupling coefficient piezoelectric thin-film bulk acoustic resonator, the structural section of which is shown in Figure 14 shown, the rear view is as Figure 15 As shown, it also has a mass-loading structure, and its only difference from Example 1 is that the bottom mass-loading film 2 is etched to form a bottom-layer grid-like mass 9 that is vertically symmetrical to the top-layer grid-like mass 7 ; This structure has the highest symmetry, which can effectively reduce the scattered waves caused by structural asymmetry.

Embodiment 3

[0057] This embodiment provides a piezoelectric film bulk acoustic resonator with high frequency and high coupling coefficient, the top view of which is as follows Figure 16 As shown, it also has a mass loading structure. The only difference between it and Embodiment 1 is that the lengths of the electrode fingers that constitute the input electrode 5 and output electrode 6 of the interdigital transducer adopt a gradual change form, from the center to both sides. The same amplitude becomes shorter; at the same time, the upper and lower boundaries (i.e. short sides) of the top grid bar mass 7 remain flush with the suspended ends of the electrode fingers, so the length of the top grid bar mass 7 also adopts Gradient form that shortens equally from the center to both sides.

[0058] The structure in this embodiment is adopted to suppress the transverse mode of the resonator. The transverse mode is a very important type of stray mode in the acoustic wave device, which not only red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com