LTCC low temperature co-fired ceramic flat surface transformer

A low-temperature co-fired ceramics, planar transformer technology, applied in transformers, fixed transformers, transformer/inductor cores, etc., can solve the problem of small planar transformers, and achieve good current distribution density consistency, high winding accuracy, The effect of good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

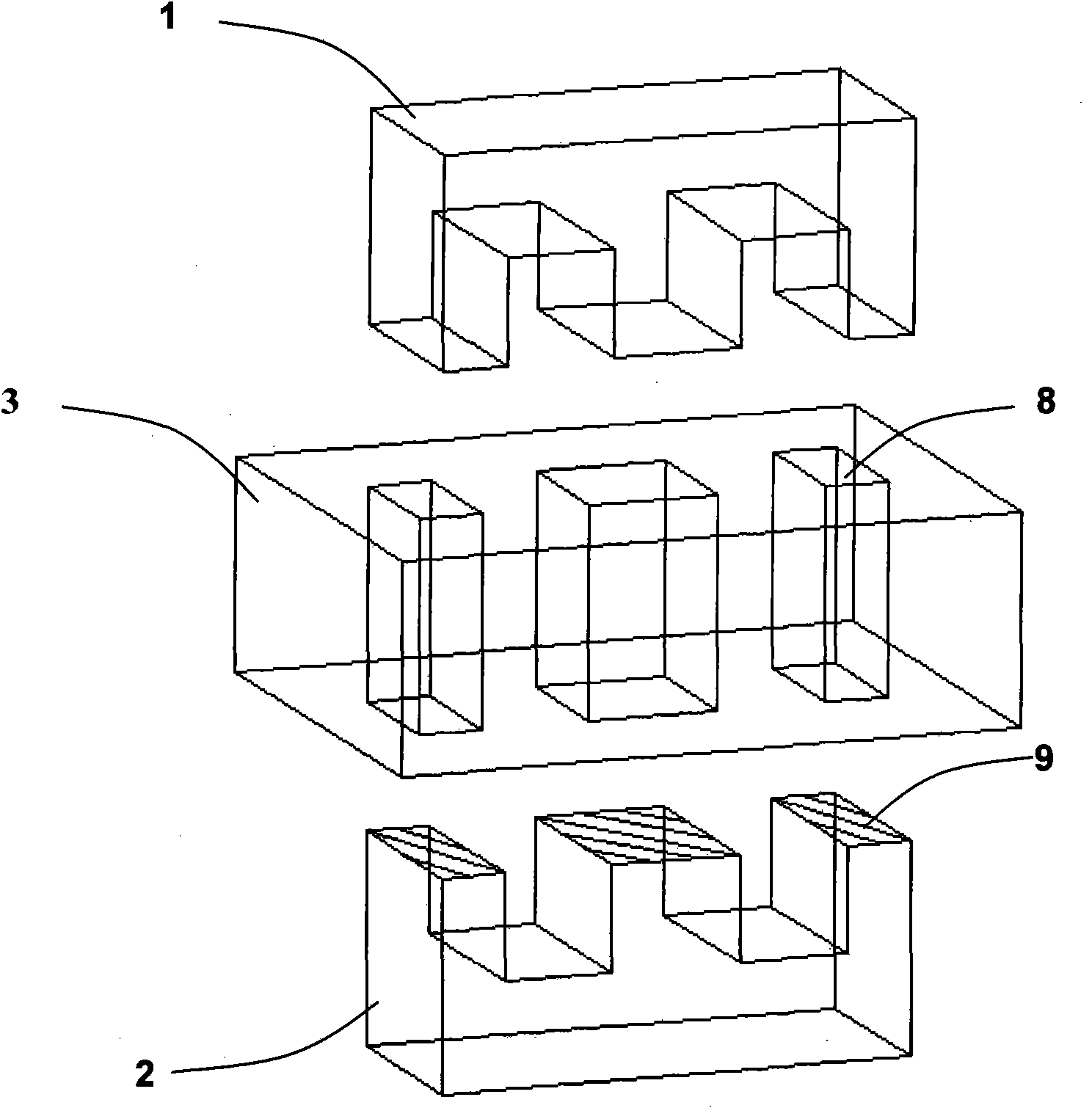

[0034] From figure 1 It can be clearly seen that the LTCC low-temperature co-fired ceramic planar transformer includes: a ferrite core composed of two low-profile E upper cores 1 and E lower cores 2, and a LTCC planar transformer with a set of planar coil components inside. substrate3.

[0035] The planar coil assembly is composed of a primary coil L1 and a secondary coil L2 with a high coupling coefficient.

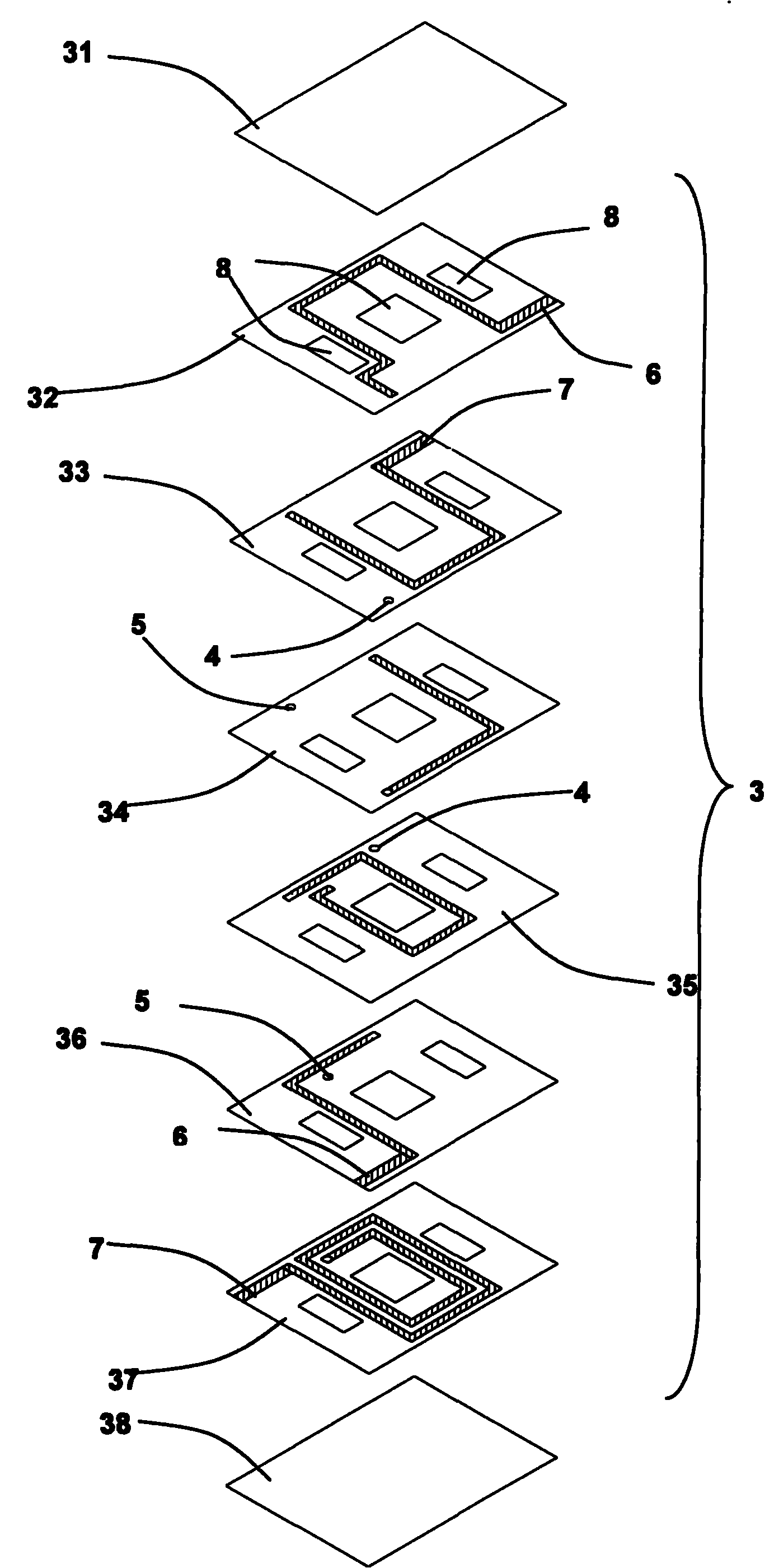

[0036] The LTCC planar transformer substrate 3 as figure 2 As shown, there are metal strips printed on the six-layer screen between the high-frequency ceramic diaphragm 31 of the surface layer, the high-frequency ceramic diaphragm 38 of the bottom layer, and the six layers stacked between the high-frequency ceramic diaphragm 31 of the surface layer and the high-frequency ceramic diaphragm 38 of the bottom layer. The high-frequency ceramic diaphragm with the shape of a conductive coil pattern is fired. The high-frequency ceramic diaphragm with metal strip-shaped condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com