Motor controller

A control device, motor technology, applied in the direction of motor control, AC motor control, motor generator control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Reference figure 1 ~ FIG. 8 illustrates an embodiment of the present invention.

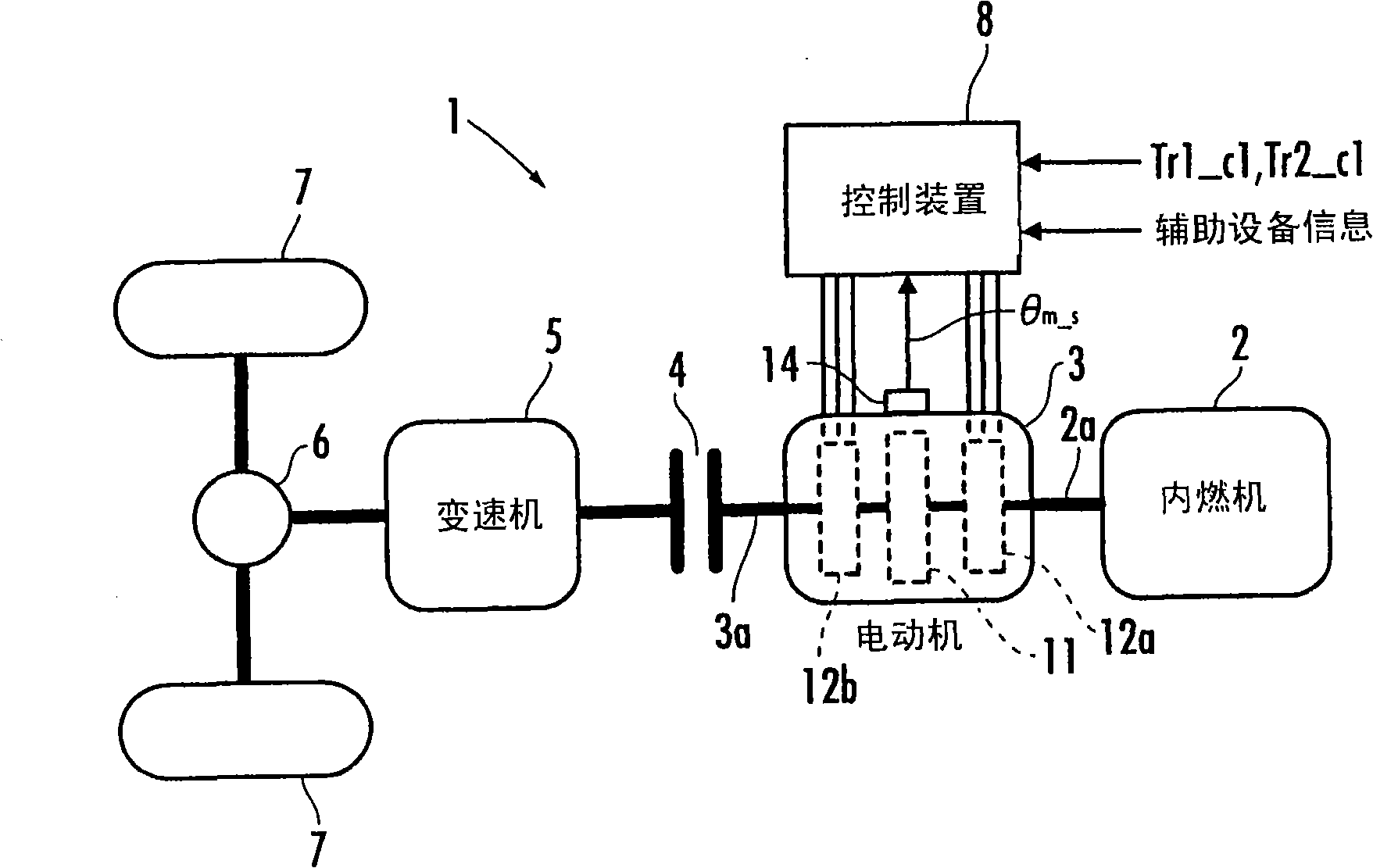

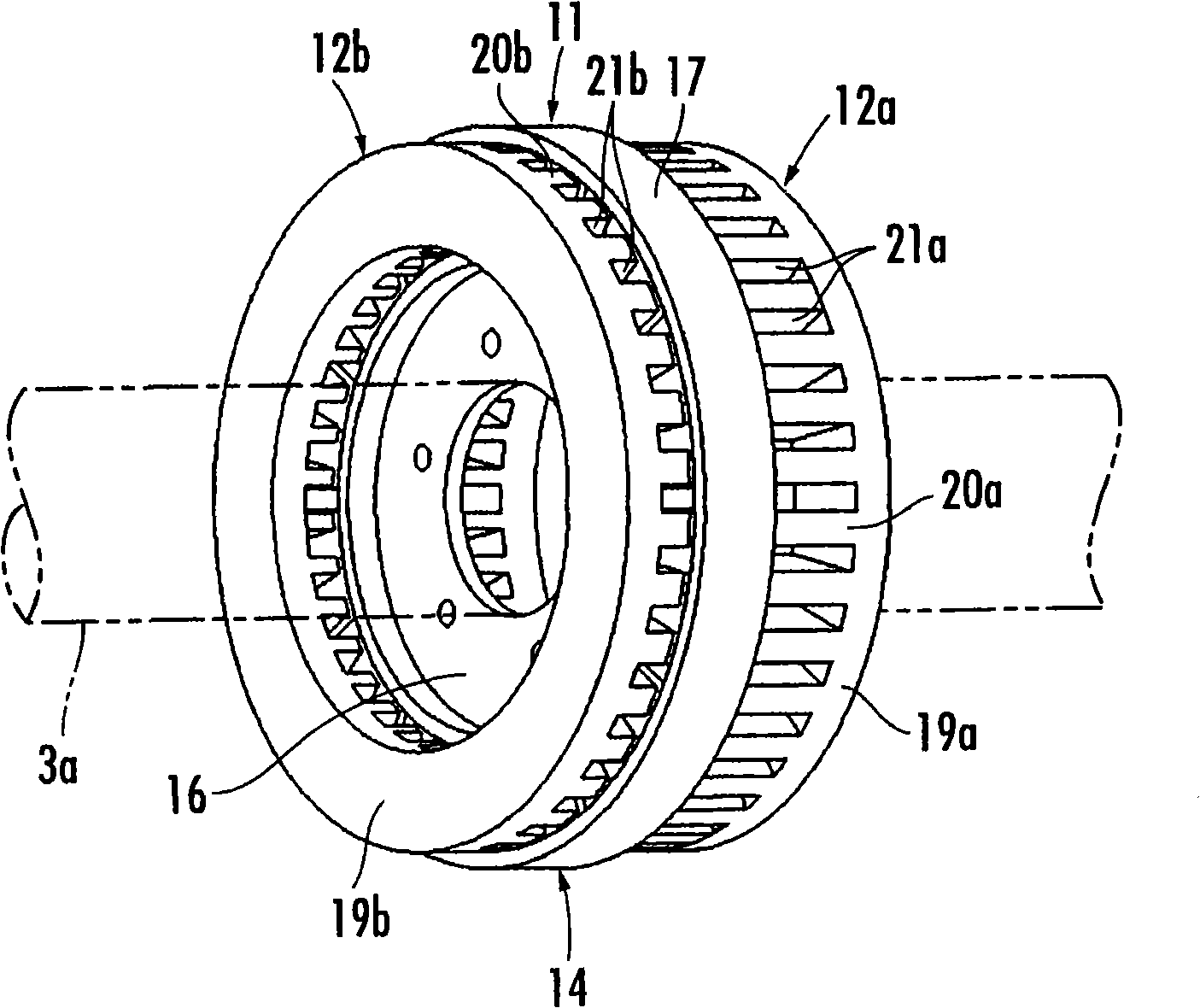

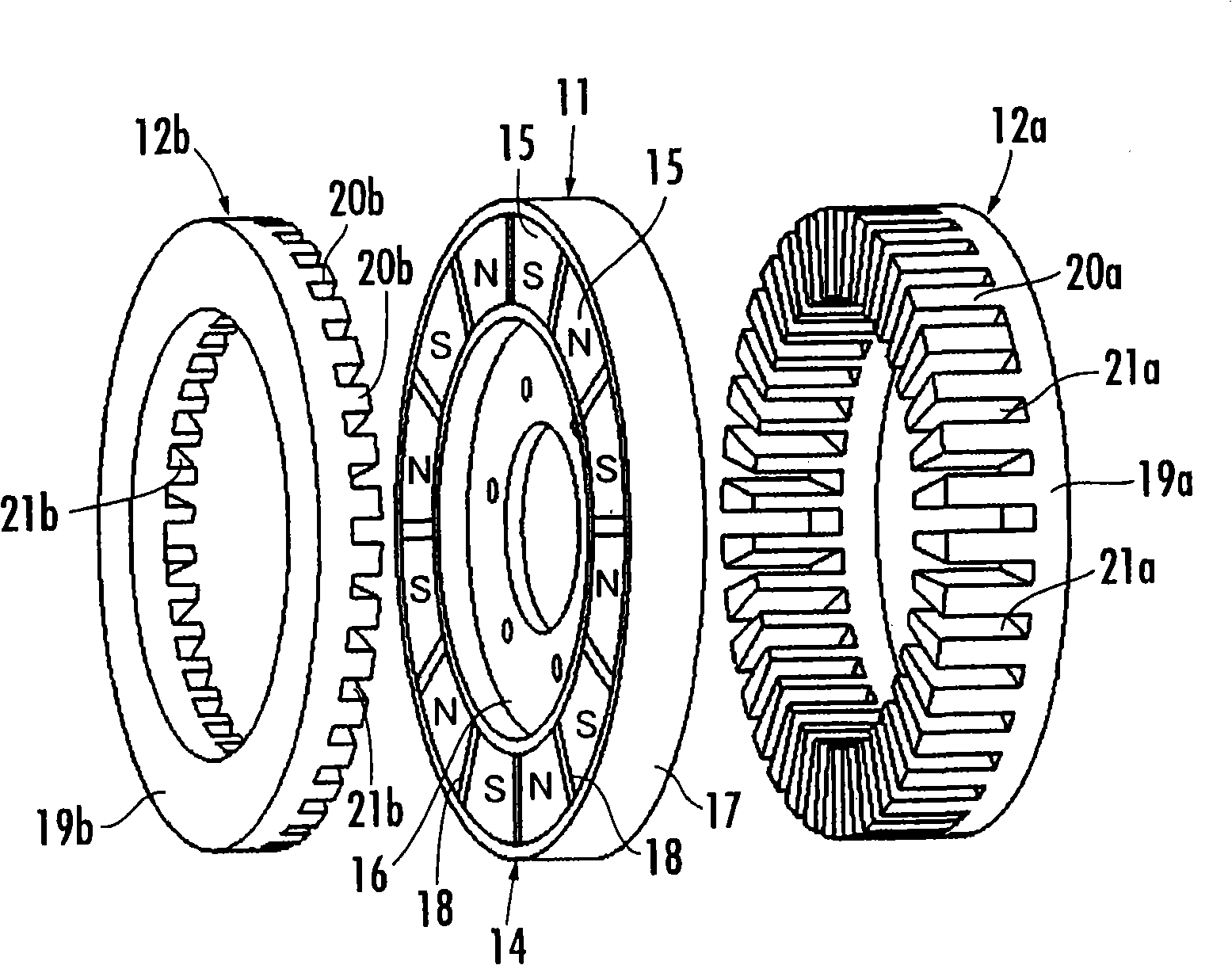

[0031] First, refer to figure 1 The general structure of a vehicle equipped with the motor control device of the present invention will be described. The vehicle 1 of the present embodiment is a parallel hybrid vehicle and has an internal combustion engine (engine) 2 as a main propulsion generating source, and an electric motor 3 as an auxiliary propulsive generating source. The electric motor 3 is an axial gap type electric motor having a rotor 11, a first stator 12a, and a second stator 12b. The electric motor 3 has a resolver 14 that detects the rotation angle of the rotor 11.

[0032] The output shaft 2a of the internal combustion engine 2 and the rotating shaft 3a that rotates integrally with the rotor 11 of the electric motor 3 are directly connected coaxially. In addition, the output shaft 2a of the internal combustion engine 2 and the rotating shaft 3a of the electric motor 3 may be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com