Method for extracting lithium from waste battery cathode material recovery dilute solution

A cathode material and waste battery technology, which is applied in the field of lithium extraction from waste battery cathode material recovery dilute solution, can solve the problems of low recovery rate of carbonate precipitation, irreparable environment, waste of resources, etc., and achieves low cost and improved recovery. rate, the effect of improving the reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

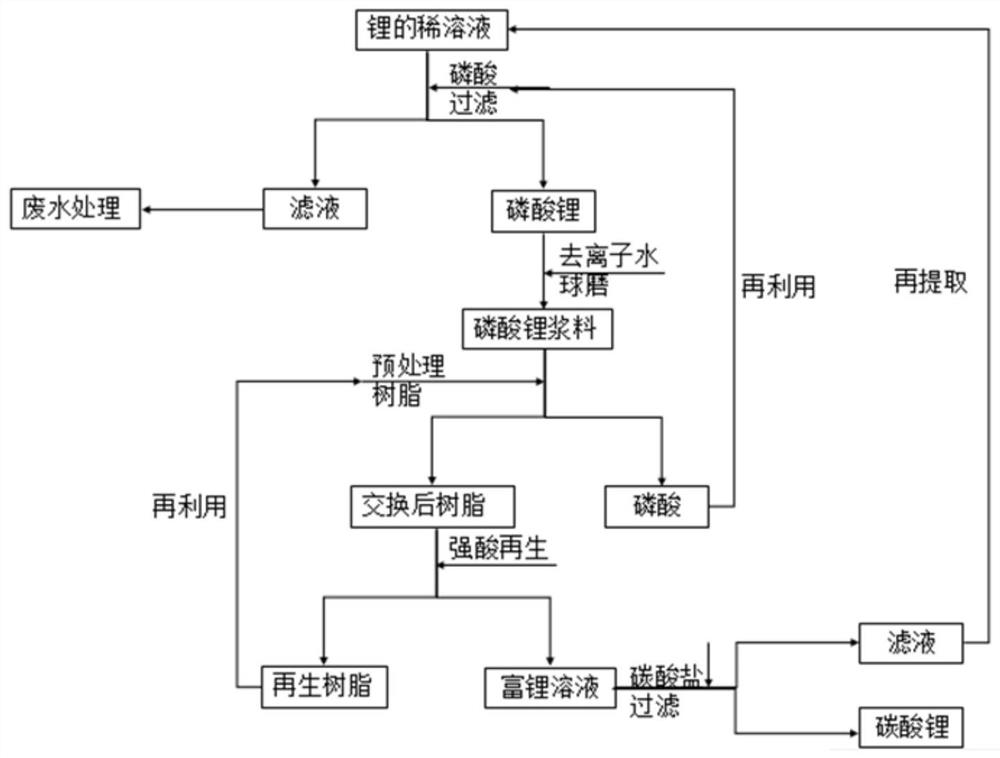

Embodiment 1

[0056] Add phosphoric acid to the lithium-containing dilute solution (2g / L) obtained after acid dissolution, extraction and separation of metal ions (nickel, cobalt, manganese), and dropwise add 2mol / L sodium hydroxide solution to adjust the pH to 10, filter 1. Washing with water to obtain lithium phosphate precipitation, the solution is directly treated as waste water. Precipitate the obtained lithium phosphate, add deionized water (the mass ratio of lithium phosphate to deionized water is 2:1) and perform ball milling for 2 hours to prepare a slurry. The obtained slurry was dissolved in the pretreated resin, aged for 8 hours at a temperature of 50°C, and filtered to obtain the ion-exchanged resin and phosphoric acid solution, wherein the phosphoric acid solution can be reused. The filtered ion-exchanged resin was regenerated with 4 mol / L sulfuric acid solution, and the aging time was 6 hours. Filtration yielded a resin and a lithium-rich solution. The obtained resin can be...

Embodiment 2

[0059] Add phosphoric acid to the lithium-containing dilute solution (2g / L) obtained after acid dissolution, extraction and separation of metal ions (nickel, cobalt, manganese), and dropwise add 3mol / L sodium hydroxide solution to adjust the pH to 12, filter 1. Washing with water to obtain lithium phosphate precipitation, the solution is directly treated as waste water. Precipitate the obtained lithium phosphate, add deionized water (the mass ratio of lithium phosphate to deionized water is 2:1.5) and perform ball milling for 4 hours to prepare a slurry. The obtained slurry was dissolved in the pretreated resin, aged for 8 hours at a temperature of 60°C, and filtered to obtain the ion-exchanged resin and phosphoric acid solution, wherein the phosphoric acid solution can be reused. The filtered ion-exchanged resin was regenerated with 4 mol / L sulfuric acid solution, and the aging time was 8 hours. Filtration yielded a resin and a lithium-rich solution. The obtained resin can ...

Embodiment 3

[0062] Add phosphoric acid to the lithium-containing dilute solution (2g / L) obtained after acid dissolution and extraction to separate metal ions (nickel, cobalt, manganese), and dropwise add 2mol / L ammonia solution to adjust the pH to 10, filter and wash with water Lithium phosphate is precipitated, and the solution is directly treated as waste water. Precipitate the obtained lithium phosphate, add deionized water (the mass ratio of lithium phosphate to deionized water is 3:1) and perform ball milling for 4 hours to prepare a slurry. The obtained slurry was dissolved in the pretreated resin, aged for 6 hours at a temperature of 55°C, and filtered to obtain the ion-exchanged resin and phosphoric acid solution, wherein the phosphoric acid solution can be reused. The filtered ion-exchanged resin was regenerated with 8 mol / L nitric acid solution, and the aging time was 4 hours. Filtration yielded a resin and a lithium-rich solution. The obtained resin can be reused, the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com