Doped and coated single crystal cathode material and method for doping and coated single crystal cathode material

A cathode material and single crystal technology, which is applied in the field of doped-coated single-crystal cathode materials and doped-coated single-crystal cathode materials, can solve the problems of increased specific surface area of particles, poor conductivity and poor environmental protection, etc. Achieve the effects of reducing the surface alkali content, high crystal quality, and high chemical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

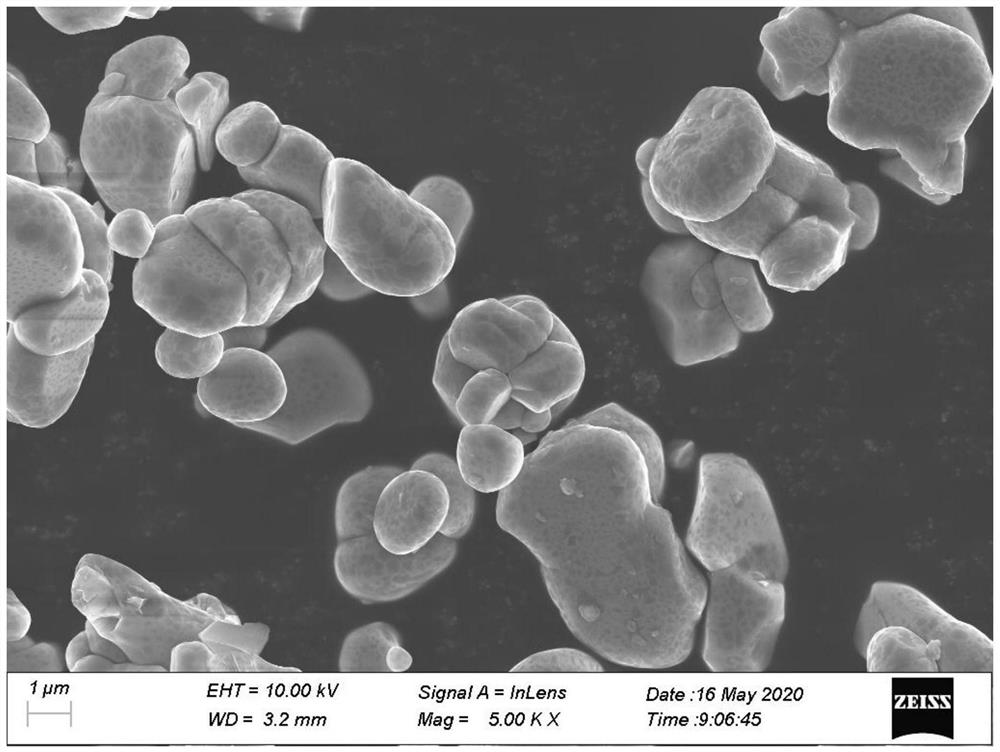

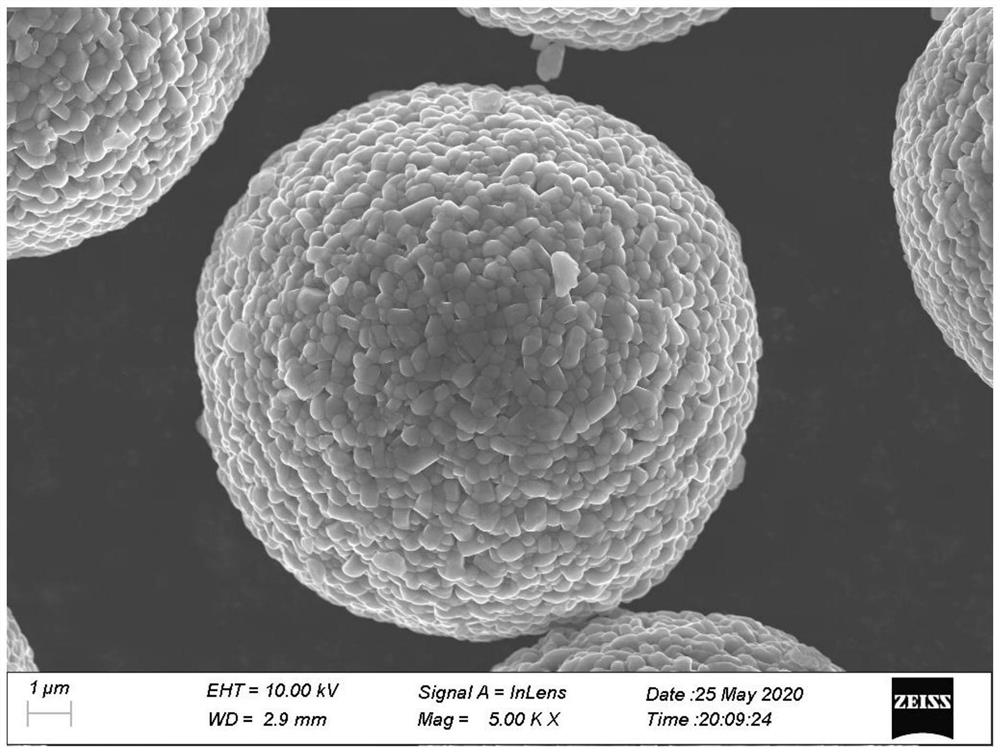

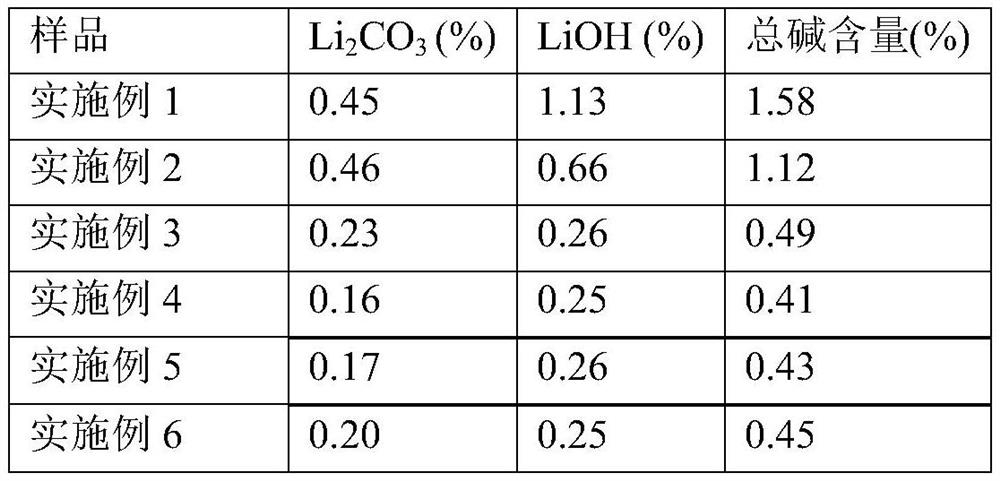

[0022] According to a typical embodiment of the present invention, a method for doping and cladding a single crystal positive electrode material is provided. Doped coated single crystal cathode material. The single crystal positive electrode material is prepared by the following steps: mixing a lithium source, a precursor, a dopant and a coating agent to obtain a raw material mixture; sintering the raw material mixture to obtain a high-temperature reaction product; and grinding and sieving the high-temperature reaction product after cooling , to obtain a doped-coated single-crystal cathode material. Applying the technical scheme of the present invention, the layered material structure is stabilized and the O 2- to O 2 Oxidation process, and prevent the transformation of the layered phase spinel structure; at the same time, the coating agent (such as nano-SiO 2 ) and residual lithium to form fast ion conductors (such as Li 2 SiO 3 ) reduce the surface alkali content, reduc...

Embodiment 1

[0034] The cathode material precursor Ni 83 mn 10 co 5 al 2 (OH) 2 , lithium source (LiOH·H 2 O) Dry mixing according to the following ratio: among them, the cathode material quaternary precursor and the lithium source (LiOH·H 2 O) Li element in molar ratio 1:1.03, SeO 2 , nano-SiO 2 According to the molar ratio of Li element: 1:0.01%, the high-speed mixing equipment is used for mixing, and the equipment is rotated to mix evenly. The mixing time: 20 minutes, the rotating speed: 2000rpm, and the mixing temperature: 25±5°C. The mixed material is sintered at 850° C. for 10 h, and the calcination process is carried out in an oxygen atmosphere (97% concentration), cooled, pulverized and sieved to obtain a doped-coated single-crystal positive electrode material with a coating layer of 0.1-1 nm.

Embodiment 2

[0036] The cathode material precursor Ni 83 mn 10 co 5 al 2 (OH) 2 , lithium source (LiOH·H 2 O) Dry mixing according to the following ratio: among them, the cathode material quaternary precursor and the lithium source (LiOH·H 2 O) Li element in molar ratio 1:1.03, SeO 2 , nano-SiO 2 According to the molar ratio of Li element: 1:0.05%, high-speed mixing equipment is used for mixing, and the equipment is rotated to mix evenly. The mixing time is 20 minutes, the rotating speed is 2000rpm, and the mixing temperature is 25±5°C. The mixed material was sintered at 850° C. for 10 h, and the calcination process was carried out in an oxygen atmosphere (97% concentration), cooled, pulverized and sieved to obtain a doped-coated single-crystal positive electrode material with a coating layer of 1-2 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com