Super capacitor cycle life test device and test method

A technology for supercapacitors and testing devices, which can be used in measuring devices, environmental/reliability testing, and electrical measurement. It can solve problems such as large power loss and inconsistent pulse widths of charge and discharge currents, and achieve low energy consumption and avoid uneven temperature rise. The effect of stabilizing and improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

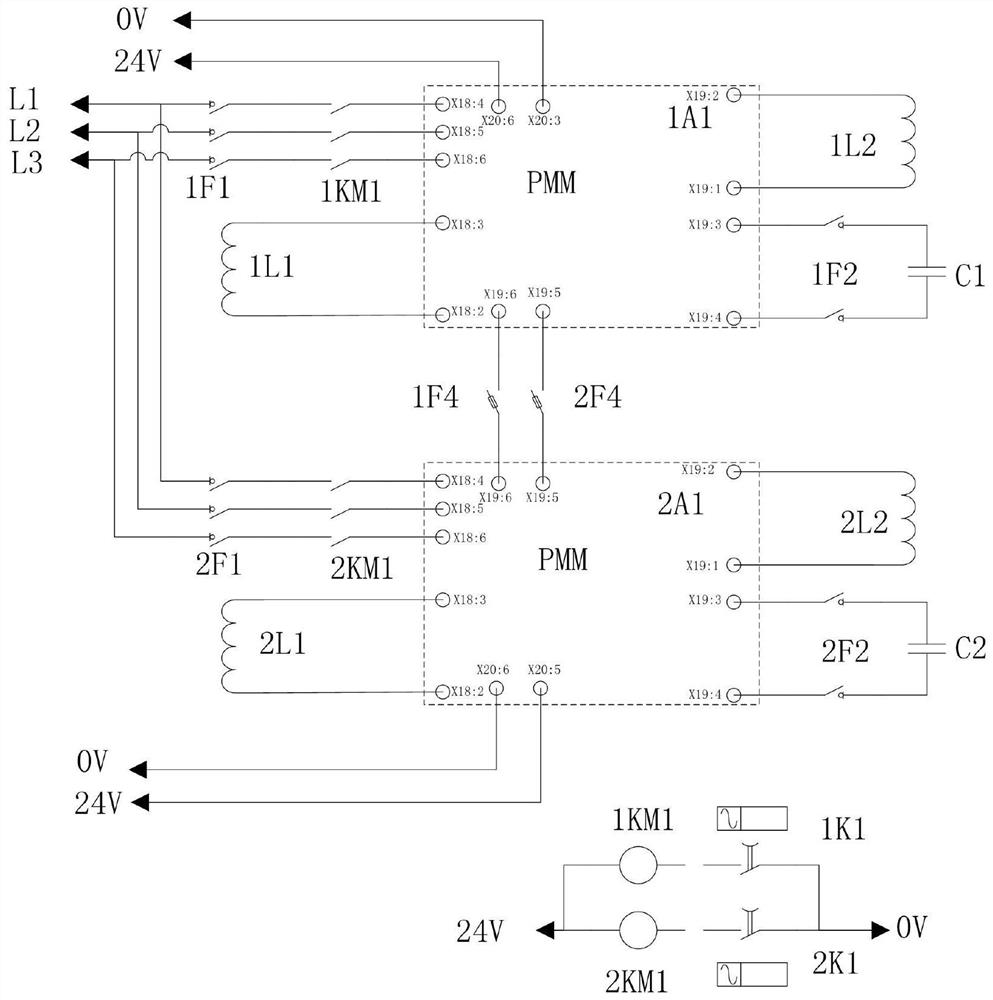

[0034] Such as figure 1 As shown, a supercapacitor cycle life testing device includes No. Ⅰ driver 1A1 and No. Ⅱ driver 2A1 connected by a common bus;

[0035] No. Ⅰ driver 1A1 is connected in series with No. Ⅰ contactor 1KM1 and No. Ⅰ starting circuit breaker 1F1 in sequence, and then connected to the power grid to obtain power, and No. Ⅰ driver 1A1 is respectively connected with No. Ⅰ filter inductor 1L1, No. Ⅰ step-up inductor 1L2 and No. Ⅰ tested Supercapacitor C1;

[0036] No. Ⅱ driver 2A1 is connected in series with No. Ⅱ contactor 2KM1 and No. Ⅱ starting circuit breaker 2F1 in sequence, and then connected to the power grid to obtain power, and No. Ⅱ driver 2A1 is respectively connected to No. Ⅱ filter inductor 2L1, No. Ⅱ step-up inductor 2L2 and No. Ⅱ to be tested Supercapacitor C2;

[0037] No. Ⅰ contactor 1KM1 and No. Ⅱ contactor 2KM1 carry out the on-off control through No. Ⅰ time relay 1K1 and No. Ⅱ time relay 2K1 respectively.

[0038] The control power of the N...

Embodiment 2

[0045] Such as figure 2 Shown, based on embodiment 1, the supercapacitor cycle life test method of application embodiment 1 device comprises the following steps:

[0046] (ⅰ) Start the test, close No. Ⅰ starting circuit breaker 1F1, No. Ⅱ starting circuit breaker 2F1, No. 1 fuse 1F4 and No. Ⅱ fuse 2 F4, and No. 1 time relay 1K1 controls No. 1 contactor 1KM1 to pull in and connect Grid-powered No. 1 driver 1A1 charges No. 1 supercapacitor C1 under test until it is fully charged;

[0047] (ii) Disconnect No. Ⅰ contactor 1KM1, and No. Ⅰ tested supercapacitor C1 supplies power to No. Ⅱ driver 2A1, and supplies power to No. Ⅱ supercapacitor C2 under test until No. Ⅱ tested supercapacitor C2 cannot continue charging. At this time Close the No. Ⅱ contactor 2KM1, and it will be supplemented by the power grid until it is fully charged;

[0048] (Ⅲ) Disconnect No. Ⅱ contactor 2KM1, and use No. Ⅱ driver 2A1 as No. 1 supercapacitor C1 to be tested, until C1 can no longer be charged, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com