Method for thermally regenerating spent acid

A thermal regeneration and waste acid technology, applied in separation methods, chemical instruments and methods, sulfur trioxide/sulfuric acid, etc., can solve the problems of expensive waste acid treatment and environmental protection requirements restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

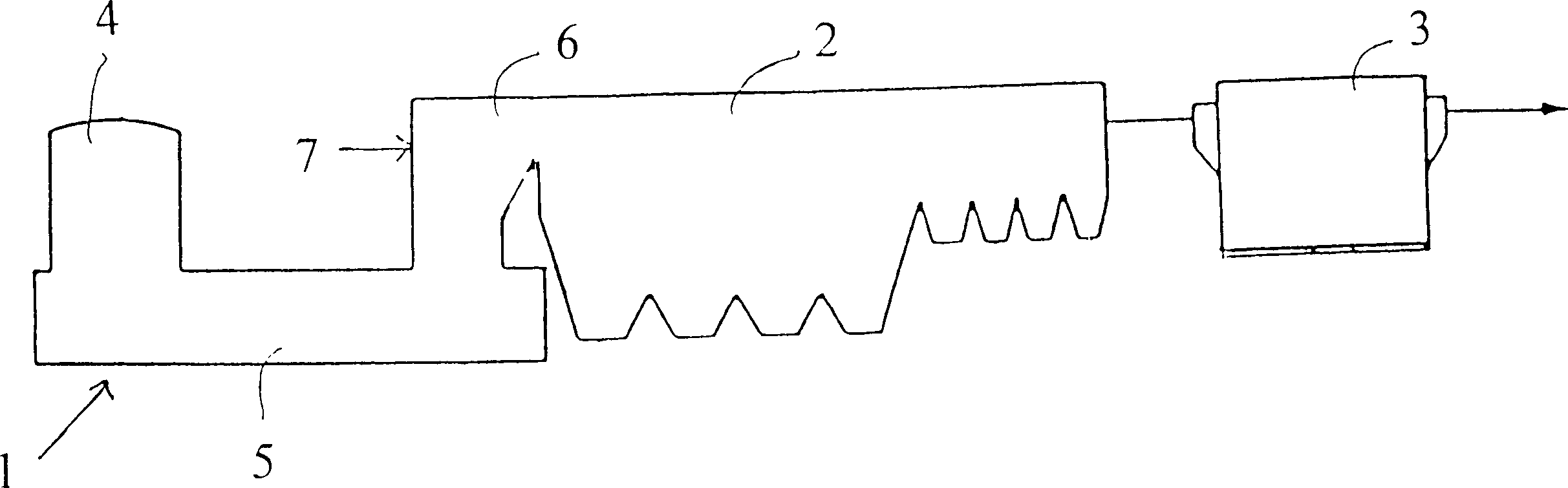

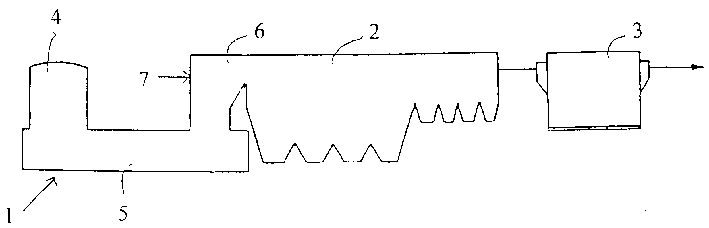

Image

Examples

Embodiment 1

[0019] The concentrated spent acid (72%H 2 SO 4 ) is fed into the rising flue of the copper flash smelting furnace with the waste acid generation rate of the whole smelting furnace, namely about 20 liters / min. The spent acid is sprayed into the uptake of the flash smelting furnace in the form of a fine mist through acid-resistant nozzles using compressed air dispersion. The waste acid pressure is 5×10 5 Pa, jet air pressure is 3×10 5 Pa. The test was run for 4 hours. The feed rate of the flash smelting furnace is 80 tons / hour, and the exhaust gas flow into the waste heat boiler is about 20000Nm 3 / h. Measurement of SO in gases after the electrostatic precipitator connected behind the boiler 3 content. The gas temperature in the boiler is reduced by about 25°C. SO 3 The regeneration rate is 90%.

Embodiment 2

[0022] From the test results of the above examples, it can be clearly seen that during the feeding process of spent acid, SO 3 The content does not increase significantly; if the spent acid is not regenerated, it will lead to SO 3 Content increased by about 50g / Nm 3 , SO in exhaust gas from nickel flash smelting furnace 3 The content increased by about 60g / Nm 3 .

[0023] From a technical point of view, the feed of the spent acid injection into the uptake of the flash smelting furnace was performed smoothly, with no signs of wear or corrosion detected in the nozzles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com