Papermaking method

A technology of starch and anionic starch, applied in the field of papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0250] The structure of hydrophobic group in embodiment 1 starch binding agent is to the influence of binding agent and starch reaction

[0251] In this example, the reaction of starch binders with different structures and native starch (only cured, not modified) was tested.

[0252]Experimental steps: (1) take a cornstarch sample and prepare 7% "standard starch solution"; (2) take an appropriate amount of standard starch solution and dilute it with deionized water until the starch concentration is 1600mg / L; (3) take the prepared starch concentration Put 500mL of the solution in a beaker and put it into a preset constant temperature water bath at 45°C; (4) According to the concentration of the prepared starch complexing agent, add 3-30mg / L starch complexing agent to make the starch : Complexing agent weight ratio is 50: 1, reacts 30 minutes then, obtains modified starch solution; (5) sampling is centrifuged (4000x g) 5 minutes, gets supernatant liquid test starch content and C...

Embodiment 2

[0259] The impact of embodiment 2 reaction time on starch binding reaction

[0260] In this example, the effect of the reaction time of the starch binder and starch on the modified starch was investigated.

[0261] Experimental steps: (1) take a cornstarch sample and prepare 7% "standard starch solution"; (2) take an appropriate amount of standard starch solution and dilute it with deionized water until the starch concentration is 1800 mg / L (or other required concentration); (3 ) Take 500mL of the prepared starch solution or OCC white water, put it in a beaker, and put it in a 45°C constant temperature water bath, and equilibrate to the specified temperature; (4) Add 30mg / L starch binder as required, and when the reaction reaches 10 , 30, 60 and 120 minutes, the sample was centrifuged (4000x g) for 5 minutes, and the supernatant was taken to test the starch content and the COD concentration.

[0262] This embodiment tests multiple anionic starch complexing agents, and their r...

Embodiment 3

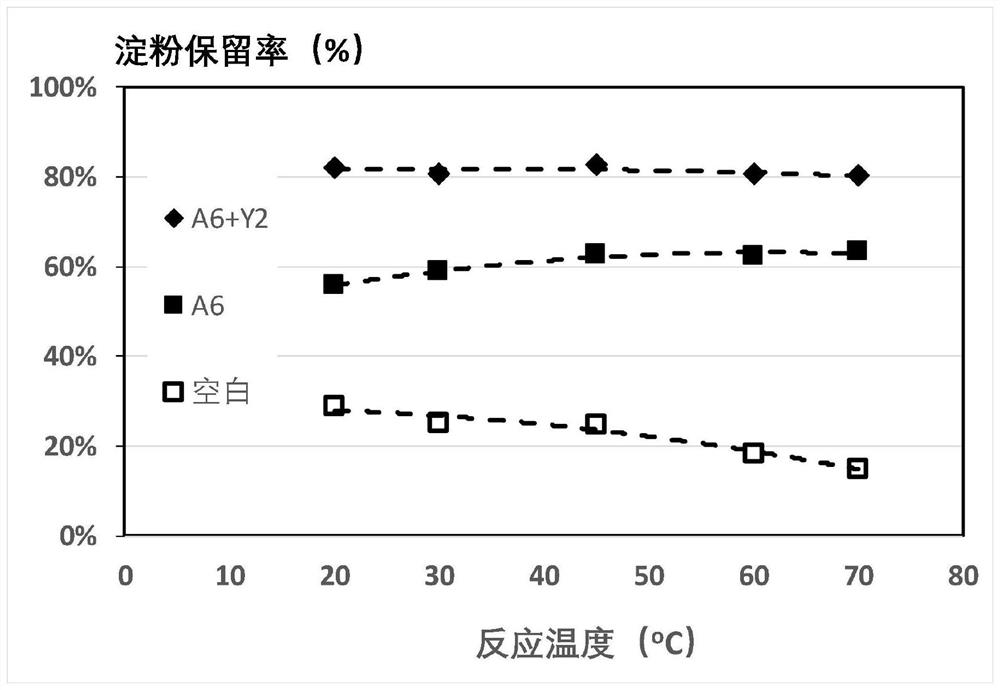

[0263] Embodiment 3 Reaction temperature is to the influence of starch binding reaction and the adsorption effect of modified starch

[0264] This embodiment examines the influence of reaction temperature on the reaction between starch binder and starch and the performance of modified starch (reaction product)

[0265] Experimental steps: (1) Take a cornstarch sample to prepare a 7% "standard starch solution"; (2) Take an appropriate amount of standard starch solution and dilute it with deionized water until the starch concentration is 600 mg / L; (3) Take the prepared starch solution 500mL, placed in a beaker, and placed in a constant temperature water bath with the required test temperature set in advance, and equilibrated to the specified temperature; (4) According to the test requirements, add 30mg / L anionic starch complexing agent A6, react for 60 minutes, Obtain the modified starch solution; (5) sample and centrifuge (4000x g) for 5 minutes, take the supernatant to test th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com