A preparation method of meter-scale large single crystal high-index surface copper foil

A high-index, copper foil technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of high cost, unsatisfactory, small area, etc., achieve low cost, reduce preparation cost, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

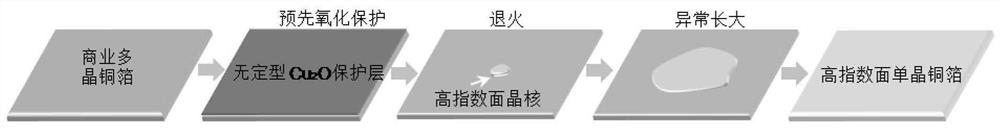

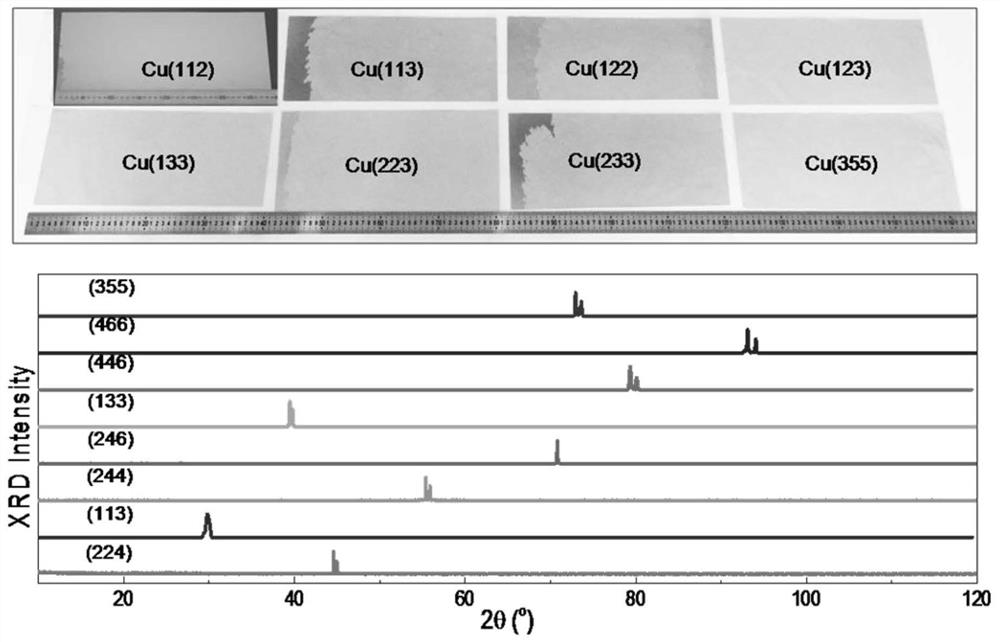

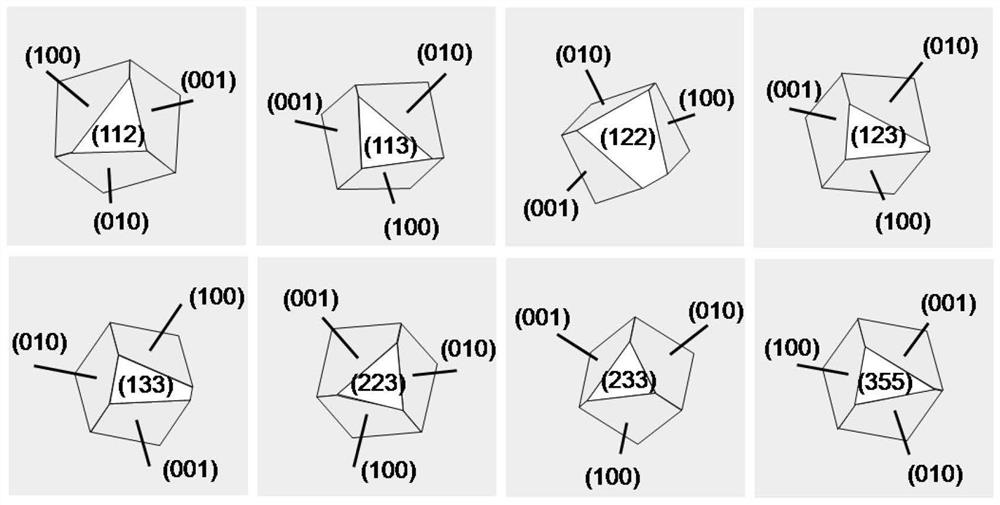

[0036] Example 1: A pre-oxidation protection of industrial-grade commercial polycrystalline copper foil, followed by annealing to prepare single crystal Cu(112), Cu(113), Cu(122), Cu(123), Cu(133), Cu(223), Cu(233), Cu(355) and other high-index surface methods include the following steps:

[0037] (1) Place the industrial-grade commercial polycrystalline copper foil without any surface treatment on the high-temperature resistant substrate or in the interlayer of the high-temperature resistant substrate, put it into a heating table, annealing furnace or chemical vapor deposition equipment, and Under the air atmosphere, start to raise the temperature, raise the temperature to 80°C-450°C, keep it for 1 minute-24 hours, and then cool down to room temperature to obtain the pre-oxidized polycrystalline copper foil.

[0038] (2), placing the pre-oxidized polycrystalline copper foil on a high temperature resistant substrate or in a high temperature resistant substrate interlayer, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com