Transparent heat-insulating ultraviolet-proof film based on photonic quasicrystal material and preparation method thereof

A photonic quasicrystal and UV protection technology, which is applied in the direction of film/flaky adhesives, coatings, adhesives, etc., can solve the problems of high sealing requirements, difficulty in wide application, high cost, etc., and achieve excellent heat insulation, excellent Transparent heat insulation and UV protection performance, structural color and transparency adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

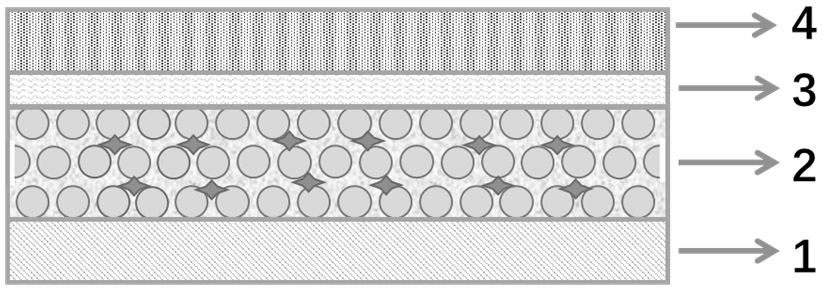

[0042] A transparent heat-shielding UV-resistant film based on photonic quasicrystal materials, such as figure 1 As shown, including a transparent substrate layer, a photonic quasicrystal functional film layer, an adhesive layer and a peelable protective layer;

[0043] Among them, the transparent substrate is a PET film with a thickness of 150 microns; the photonic quasicrystal functional film layer is a photonic crystal film composed of core-shell microspheres with a particle size of 280 nanometers and cesium tungsten bronze particles with a particle size of 90 nanometers, with a thickness of 150 microns. Micron;

[0044] The photonic quasicrystal functional film layer is coated on the transparent PET substrate by roll coating, and then the photonic quasicrystal functional film layer is obtained by uniaxially pressing the nuclear microspheres and functional nanoparticles in the structured film;

[0045] Then, a polyacrylate adhesive layer is coated on the photonic quasicrys...

Embodiment 2

[0058] The structure of the transparent heat-insulating and anti-ultraviolet film is the same as in Example 1, and the specific preparation process is as follows:

[0059] (1) Preparation of monodisperse core-shell polymer emulsion

[0060] Using the same experimental procedure as in Example 1, in the first step of the formula, the addition of sodium lauryl sulfate is changed to 1.80 grams to prepare the seed emulsion, and then the core-shell emulsion is obtained through gradual polymerization, and the final product polymer microspheres The size is 252nm, the polydispersity index PDI of the microsphere is 0.12;

[0061] (2) Preparation of prefabricated emulsion dispersion

[0062] The same experimental procedure as in Example 1 was used to prepare the functional nanoparticle aqueous slurry, and then 50g of the infrared functional nanoparticle slurry was mixed with 1000g of the core-shell microsphere emulsion and stirred evenly to obtain a photonic quasicrystal functional thin...

Embodiment 3

[0067] The structure of the transparent heat-insulating and anti-ultraviolet film is the same as in Example 1, and the specific preparation process is as follows:

[0068] (1) Preparation of monodisperse core-shell polymer emulsion

[0069] Using the same experimental procedure as in Example 1, in the first step of the formula, the addition of sodium lauryl sulfate is changed to 2.10 grams to prepare the seed emulsion, and then the core-shell emulsion is obtained through gradual polymerization, the size of the polymer microspheres 231nm, the polydispersity index PDI of microspheres is 0.10;

[0070] (2) Preparation of prefabricated emulsion dispersion

[0071] Using the same experimental procedure as in Example 1 to prepare functional nanoparticle aqueous slurry, then mix 60g of infrared functional nanoparticle slurry with 1000g of core-shell microsphere emulsion, and stir evenly to obtain a photonic quasicrystal functional thin film layer prefabricated emulsion dispersion; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com