Solar silicon wafer recycling treatment device

A technology for solar silicon wafers and processing devices, which is applied to the cleaning method using tools, the cleaning method using gas flow, the cleaning method and utensils, etc. and other problems to achieve the effect of improving the degree of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

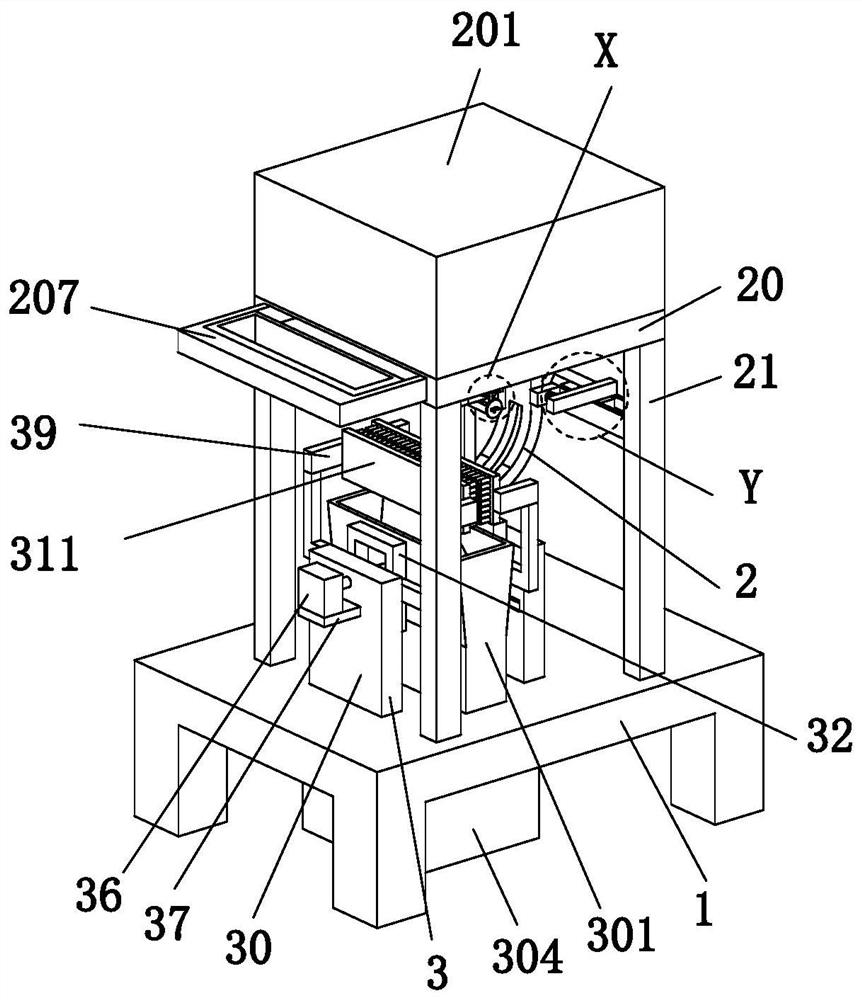

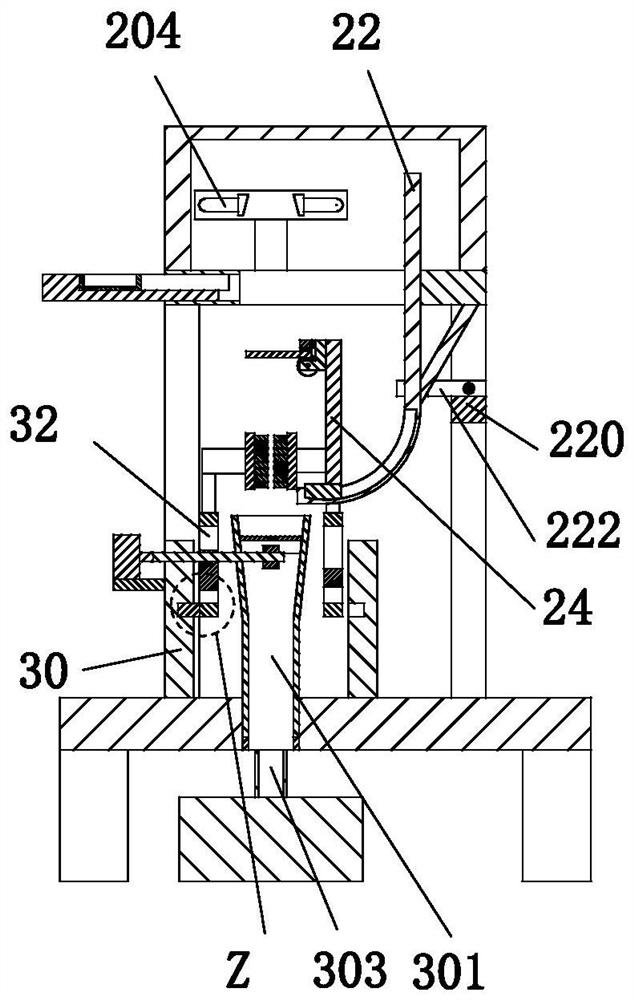

[0035] Such as Figure 1 to Figure 11 As shown, a solar silicon chip recovery and reuse processing device includes a workbench 1, a clamping mechanism 2 and a cleaning mechanism 3. The upper end surface of the workbench 1 is equipped with a clamping mechanism 2, and the left side of the clamping mechanism 2 A cleaning mechanism 3 is arranged on the side, and the lower end of the cleaning mechanism 3 is connected to the upper end surface of the workbench 1 .

[0036] The clamping mechanism 2 includes a base plate 20, a bracket 21, a track plate 22, a No. 1 electric slider 23, a pole 24 and a clamping group 25. The base plate 20 is located directly above the upper end surface of the workbench 1, and the lower end of the base plate 20 Brackets 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com