Confinement layer structure and its manufacturing method, semiconductor laser and its manufacturing method

A manufacturing method and laser technology, applied to the structure of semiconductor lasers, lasers, and optical waveguide semiconductors, can solve problems such as high Al content and performance degradation of semiconductor lasers, and achieve improved performance, improved conductivity, and improved slope efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

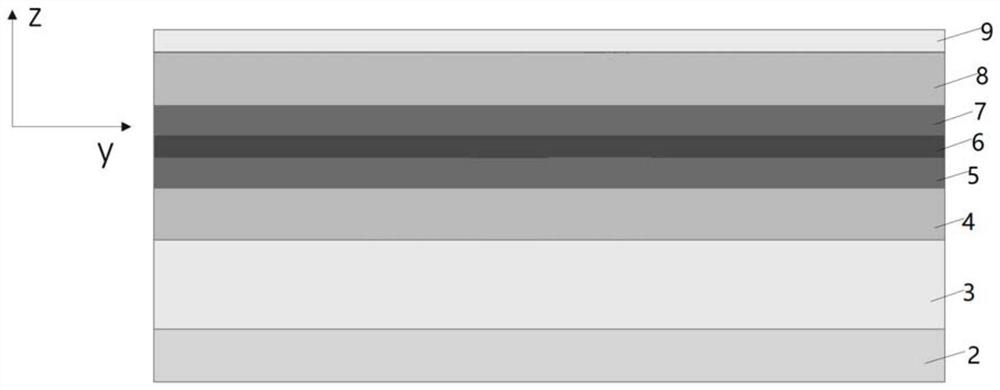

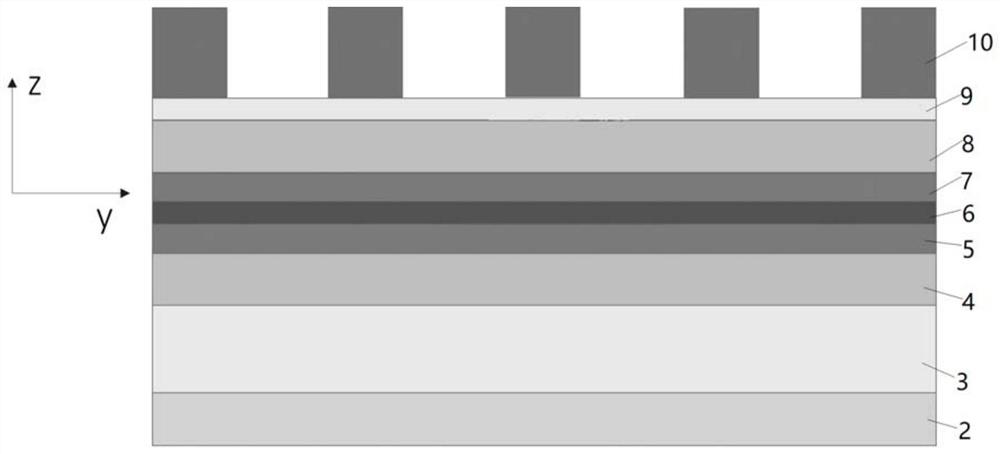

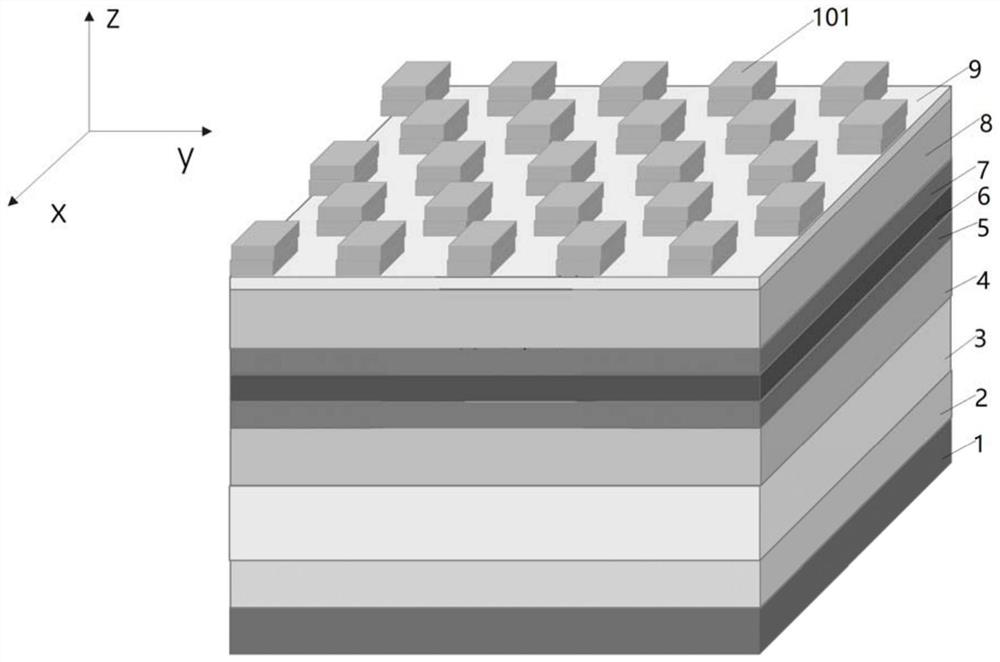

[0041] This embodiment provides a semiconductor laser, see Figure 1 to Figure 5 , which includes an N-type GaAs (gallium arsenide) substrate, a semiconductor laser structure, a P-type GaAs cap layer 9 and a confinement layer structure 10 arranged in sequence from bottom to top. Wherein, the confinement layer structure may also be referred to as a mixed confinement layer.

[0042]Wherein, the semiconductor laser structure described in the embodiment of the present invention mainly refers to other functional layer structures in the semiconductor laser except the substrate, the upper confinement layer, and the contact layer. The semiconductor laser structure is located above the N-type GaAs substrate 1, which includes N Type GaAs buffer layer 2, N-type AlGaAs (aluminum gallium arsenide) lower confinement layer, N-type AlGaAs lower waveguide layer 4, GaAs quantum barrier layer 5, InGaAs (gallium indium arsenide) quantum well layer, GaAs quantum barrier layer 7 and P-type AlGaAs ...

Embodiment 2

[0053] This embodiment provides a method for manufacturing a semiconductor laser, such as Figure 6 and Figure 7 As shown, it includes the following steps:

[0054] S11: growing a semiconductor laser structure on a substrate. Specifically, the substrate is an N-type GaAs substrate 1, which is first grown into an N-type GaAs substrate 1 in a Metal-organic Chemical Vapor Deposition (MOCVD) device, and then sequentially grown on an N-type GaAs substrate. 1 grow N-type GaAs buffer layer 2, N-type AlGaAs lower confinement layer 3, N-type AlGaAs lower waveguide layer 4, GaAs quantum barrier layer 5, InGaAs quantum well layer 6, GaAs quantum barrier layer 7 and P-type AlGaAs upper waveguide layer 8. Alternatively, the substrate and the semiconductor laser structure can be grown in a molecular beam epitaxy (MBE) device.

[0055] S12: growing a capping layer on the semiconductor laser. Specifically, the capping layer is a P-type GaAs capping layer with a thickness of 5nm-10nm. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com