Carbon-containing material light-weight grid for lead-acid storage battery and preparation method of carbon-containing material light-weight grid

A lead-acid battery, lightweight technology, applied in the direction of lead-acid batteries, battery electrodes, circuits, etc., can solve the problems of easy growth of the grid, poor creep resistance, short service life, etc., to reduce the quality of the grid, Strong electrical conductivity, lowering the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

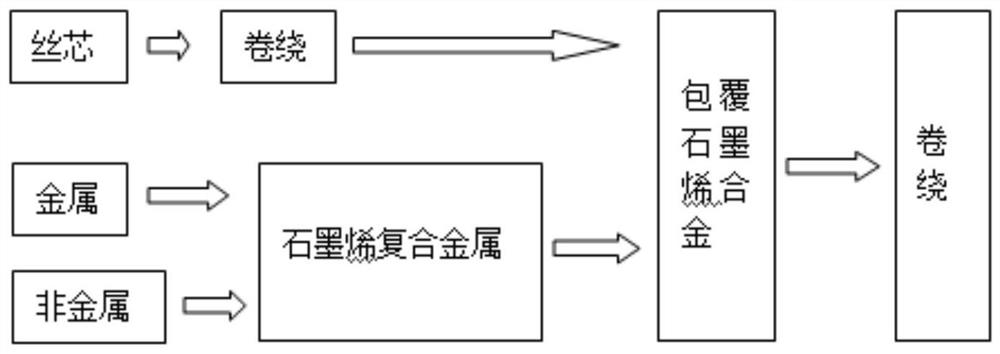

[0049] The invention discloses a method for preparing a carbon-containing material lightweight grid for lead-acid batteries, which specifically comprises the steps of using graphene as an additive, heating and melting, dooming, or heating, melting and injection molding into a rod blank.

[0050]

[0051]

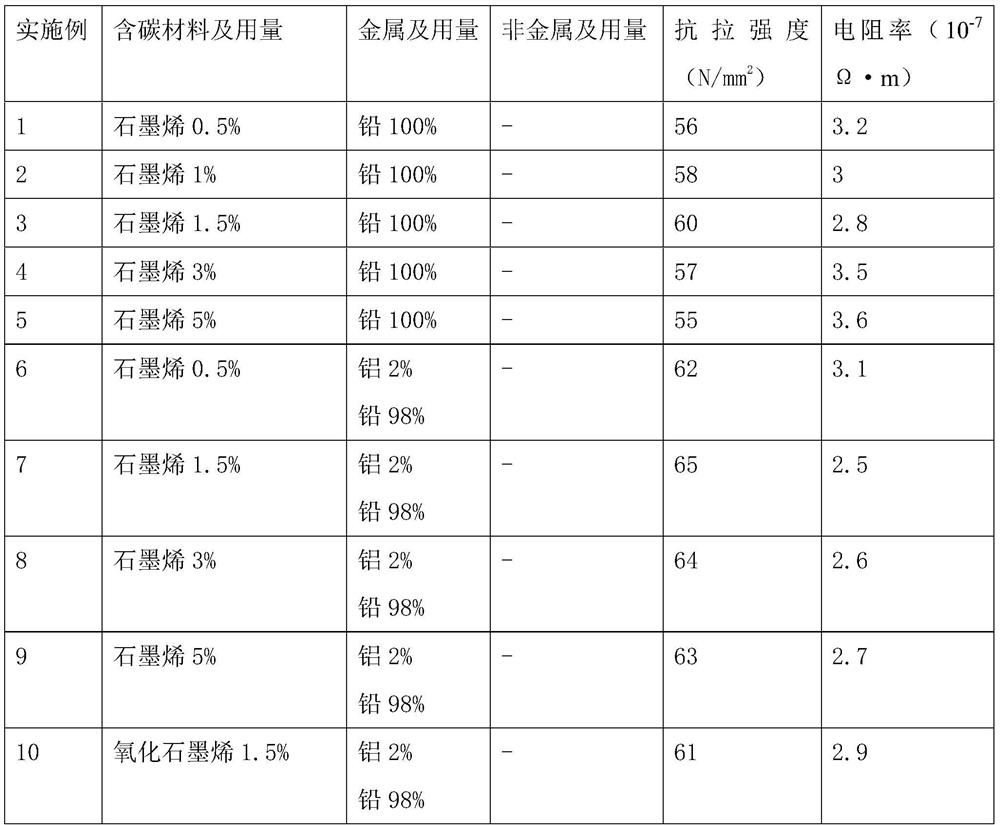

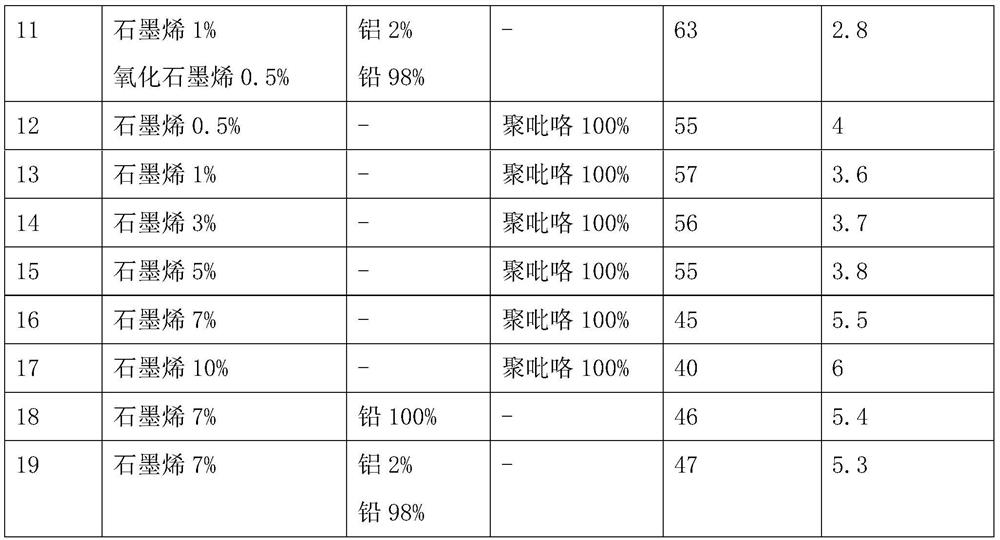

[0052] From the above experimental data, it can be seen that when the carbon-containing composite material is used to make a skin material with a strip-shaped skin-core structure or a tubular material with a strip-shaped tubular structure, the performance is better when the content of the carbon-containing material is 0.01%-5%. More preferably, the content of the carbonaceous material is 0.5%-3%. If the content of graphene is too much, the performance of the material will be reduced instead. Regarding the selection of carbon-containing materials, after adding graphene oxide, its tensile strength and electrical conductivity will decrease. Therefore, the carbon-containing...

Embodiment 2

[0054] A kind of preparation method of carbonaceous material lightweight grid for lead-acid storage battery of the present invention comprises the following steps:

[0055] (1) Put the rod blank of the carbon-containing composite conductive material for the grid into the groove of the extrusion wheel;

[0056] (2) Start the motor to rotate the extrusion wheel. Under the friction of the wheel groove wall, the rod billet is drawn into the arc-shaped extrusion cavity formed by the extrusion wheel and the cavity. Under the action, the rod blank is melted, extruded through the die to form a pipe, which is coated on the surface of the core material to form a carbon-containing composite conductive wire, or the pipe formed by extrusion through the die is directly used to make a grid, and the core is not filled other materials. In this embodiment, by controlling the thickness of the rod blank and the specifications of the mold, tubular skin layers of different specifications are prepa...

Embodiment 3

[0058] By adjusting the parameters of the above-mentioned ribs, the rib materials in the table below were prepared, and prepared into grids, and the cycle times of the batteries were measured after completion. The calculation of the lightweight parameters in the table below is based on the mass A of the lead grid of the same thickness, and B is the mass of the grid in the embodiment of the present invention, and the lightweight is (A-B) / A×100%.

[0059]

[0060]

[0061] It can be seen from the above-mentioned embodiments that on the basis of the first group of embodiments, changing the thickness ratio of the skin layer / core layer can change the electrical conductivity of the grid material, the degree of light weight and the number of cycles of 80% deep discharge, and when When the thickness of the skin layer / core layer is 0.2-2, the performance of the grid material is better, more preferably 0.2-1, wherein the thickness of the skin layer is 0.05-2 mm, and the diameter of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com