Metal roof waterproof laying machine

A technology of metal roofing and paving machines, which is applied in the direction of roofing, metal processing equipment, abrasive jet machine tools, etc., can solve the problems of environmental damage on the surrounding surface and no inter-structure of fine sand, so as to reduce pollution, reduce manpower consumption, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

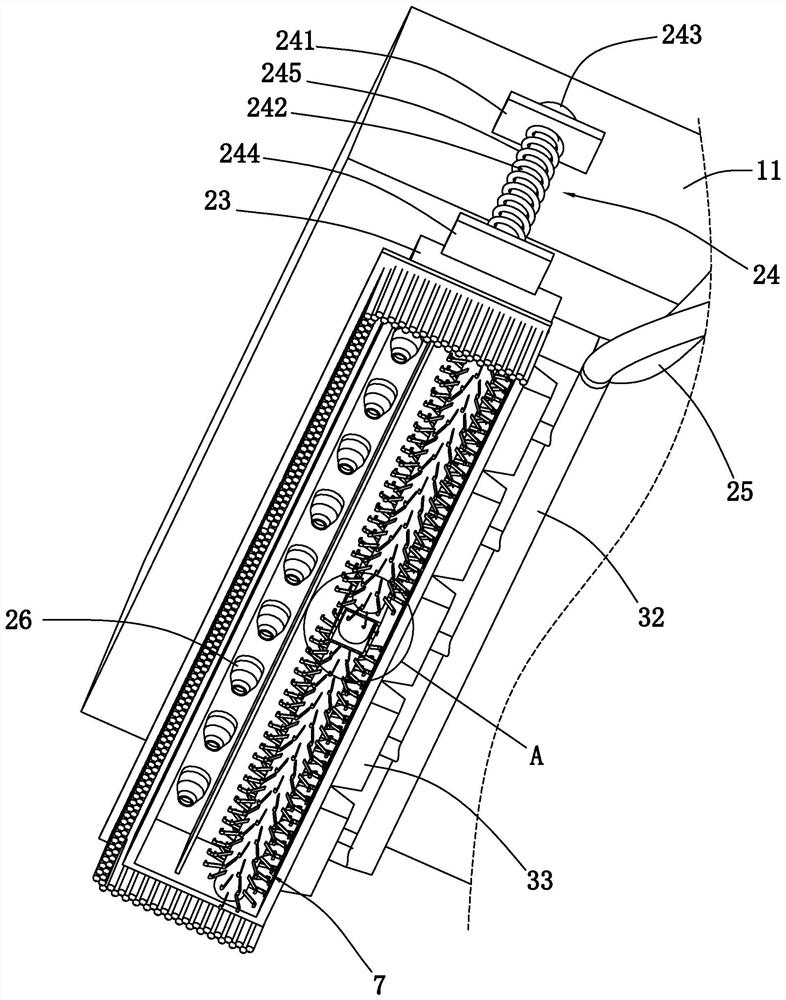

[0046] A metal roof waterproof paving machine, such as figure 1 As shown, including the car body 11, the car body 11 is provided with a derusting device 2, a dust suction mechanism 3 and a spraying mechanism 4 by one side of the advancing direction of the car body 11; the bottom of the car body 11 is provided with two mutually parallel moving Agency 5.

[0047] Such as figure 1 and figure 2 As shown, the derusting device 2 includes a high-pressure sand box 21 vertically fixed in the car body 11, and the inside of the high-pressure sand box 21 is loaded with fine sand for derusting; 21 provides a high-pressure pipe 22 for high-pressure gas; the bottom of the car body 11 is also provided with a dust collection case 23 below the high-pressure sand box 21, and the dust collection case 23 is horizontally arranged along the width direction of the car body 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com