Gas-shield welding wire with fire-resistant and weather-resistant characteristics

A fire-resistant, weather-resistant, gas-shielded welding technology, which is applied to welding media, manufacturing tools, welding equipment, etc., can solve the problems that the tensile strength of welding wire at room temperature cannot be stably achieved, the yield strength at room temperature cannot be stably achieved, and does not have fire resistance. , to achieve the effects of improving metallurgical quality and low temperature impact toughness, ensuring weather resistance, and improving compactness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further specifically described below in conjunction with specific examples. The explanations and illustrations do not constitute undue limitations on the technical solution of the present invention. All deformations directly derived or associated from the content disclosed in the present invention belong to the protection scope of the present invention.

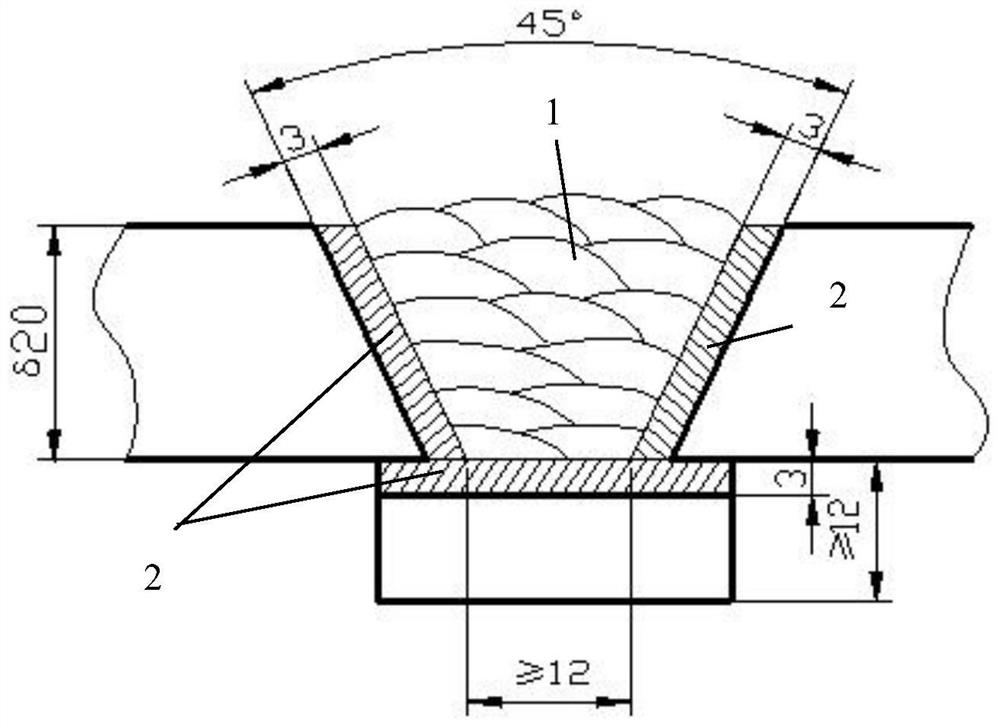

[0034] The welding wire of the present invention is produced through the following steps: smelting, refining, mold casting into an ingot, heating for controlled rolling of the wire rod, and continuous hot rolling into a 5.5mm welding wire coil. After the component inspection and surface inspection are qualified, the wire rod is annealed and heat-treated after shelling, pickling, and rough drawing to 2.2-3.5mm, and then drawn, surface degreased, copper-plated, close-packed layer winding, and finally produced 1.2mm Welding wire, packed into reels. Specific examples of welding wire of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com