Method for brazing and sealing palladium alloy thin-walled tube

A technology of thin-walled tubes and palladium alloys, applied in metal processing, tubular objects, welding equipment, etc., can solve problems such as low production efficiency, inaccurate heating and temperature control, and reduced purification performance, so as to achieve convenient positioning and clamping, and avoid mutual Uniform and reliable contact and weld seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment includes the following steps:

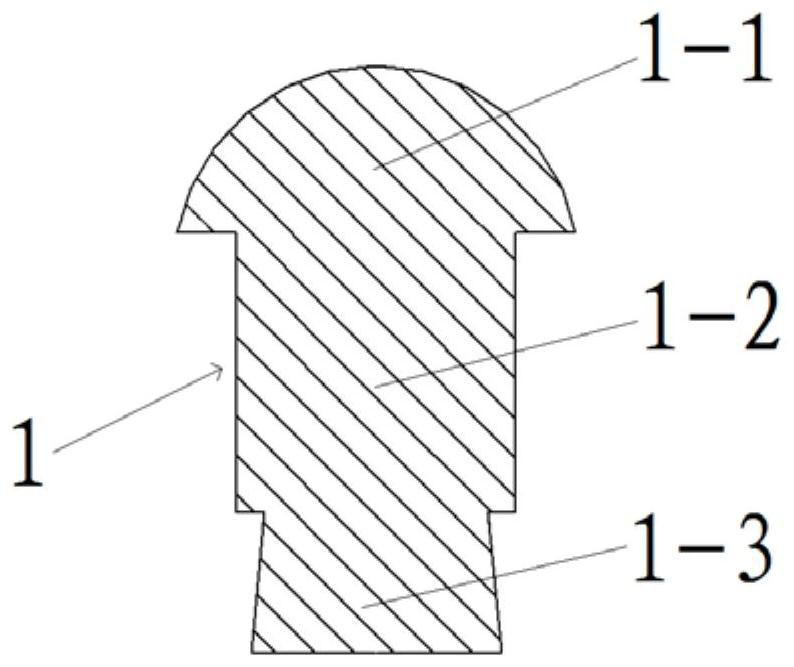

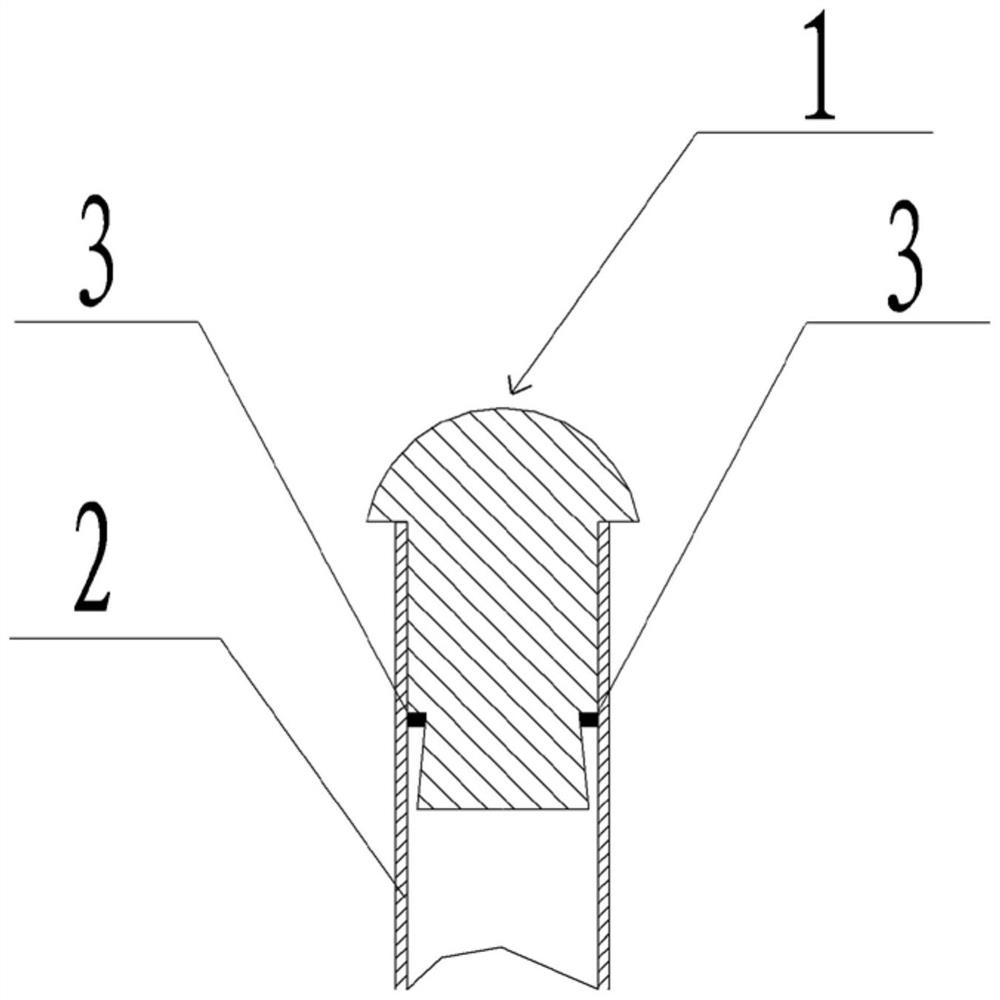

[0030] Step 1. Install the solder 3 around the upper end of the pipe head main body 1-2, and then insert the pipe head 1 into the palladium alloy thin-walled pipe 2, see figure 2 The diameter of the lower end surface of the pipe head cap 1-1 is 1 mm larger than the diameter of the cross section of the pipe head body 1-2; the diameter of the bottom surface of the pipe head tail 1-3 is larger than that of the pipe head The diameter of the cross section of the main body 1-2 is 0.3mm smaller; the palladium alloy thin-walled tube 2 is a palladium-yttrium alloy thin-walled tube of Φ2mm×0.08mm (outer diameter×wall thickness); the solder 3 has a quality of 0.2g AgCu28 welding wire; the material of the pipe head 1 is N6 grade pure nickel; the assembly gap between the pipe head 1 and the palladium alloy thin-walled pipe 2 is 0.02mm;

[0031] Step 2, the palladium alloy thin-walled tube 2 inserted into the tube head 1 in step 1 is ...

Embodiment 2

[0034] This embodiment includes the following steps:

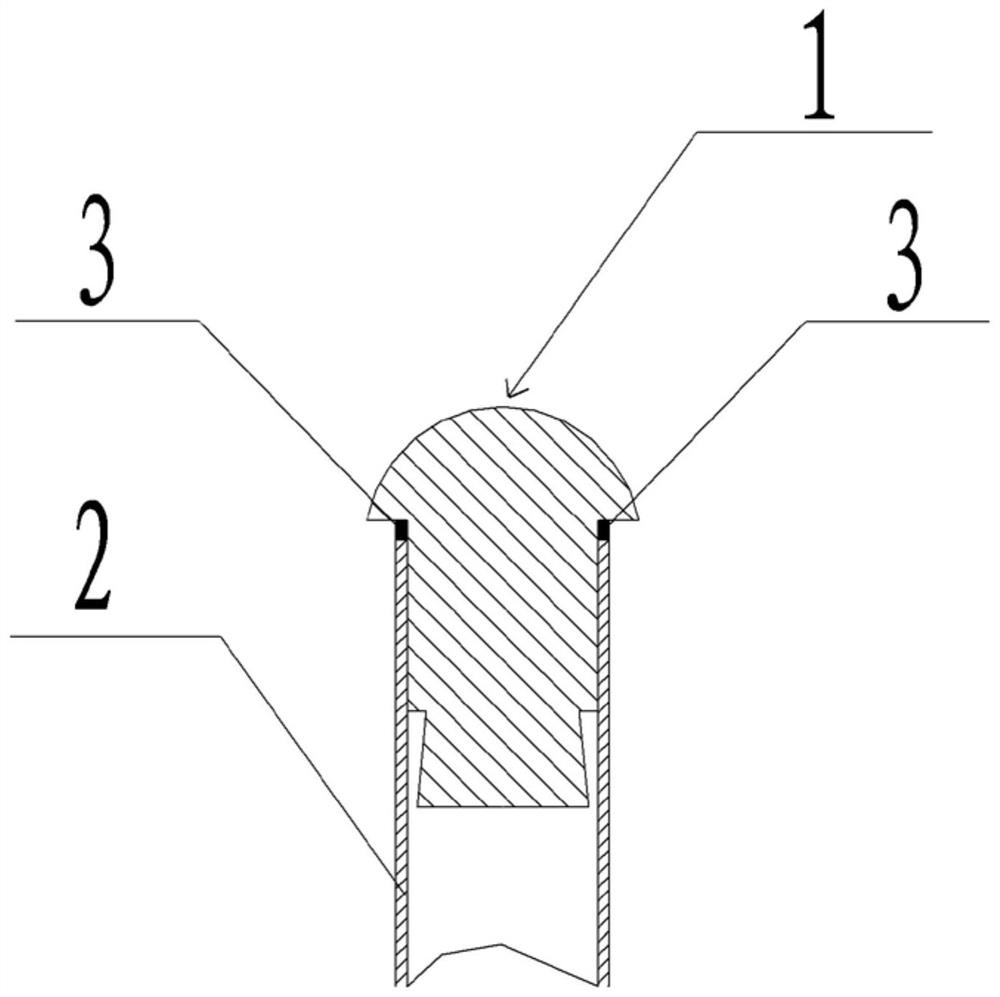

[0035] Step 1. Install the solder 3 around the upper end of the pipe head and tail 1-3, and then insert the pipe head 1 into the palladium alloy thin-walled pipe 2, see image 3 The diameter of the lower end surface of the pipe head cap 1-1 is 1 mm larger than the diameter of the cross section of the pipe head body 1-2; the diameter of the bottom surface of the pipe head tail 1-3 is larger than that of the pipe head The diameter of the cross section of the main body 1-2 is 0.3mm smaller; the palladium alloy thin-walled tube 2 is a palladium-silver alloy thin-walled tube of Φ2mm×0.08mm (outer diameter×wall thickness); the solder 3 has a quality of 0.2g Ag foil strip; the material of the pipe head 1 is Monel 400 alloy; the assembly gap between the pipe head 1 and the palladium alloy thin-walled pipe 2 is 0.01mm;

[0036] Step 2, the palladium alloy thin-walled tube 2 inserted into the tube head 1 in step 1 is vertically put...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1. Install the solder 3 around the upper end of the pipe head main body 1-2, and then insert the pipe head 1 into the palladium alloy thin-walled pipe 2; the diameter of the lower end surface of the pipe head cap 1-1 is The diameter of the cross-section of the main body 1-2 of the pipe head is 0.3 mm larger; the diameter of the upper bottom surface of the tail 1-3 of the pipe head is 1 mm smaller than the diameter of the cross-section of the main body 1-2 of the pipe head; the palladium The alloy thin-walled tube 2 is a palladium-copper alloy thin-walled tube of Φ2mm×0.08mm (outer diameter×wall thickness); the brazing material 3 is BCu62ZnNiMnSi-R solder paste with a quality of 0.3g; the material of the tube head 1 It is CuNi30 alloy; the assembly gap between the pipe head 1 and the palladium alloy thin-walled pipe 2 is 0.02mm;

[0041] Step 2, the palladium alloy thin-walled tube 2 inserted into the tube head...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com