Device for cleaning inner wall of oil-stain-containing waste gas exhaust pipeline

A technology for exhaust gas discharge and inner wall cleaning, which is applied to pipe components, cleaning hollow objects, and removing solid residues, etc. It can solve problems such as easy adhesion of oil stains and particles, reduced service life of pipelines, corrosion of pipeline inner walls, etc. Improve the service life and reduce the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

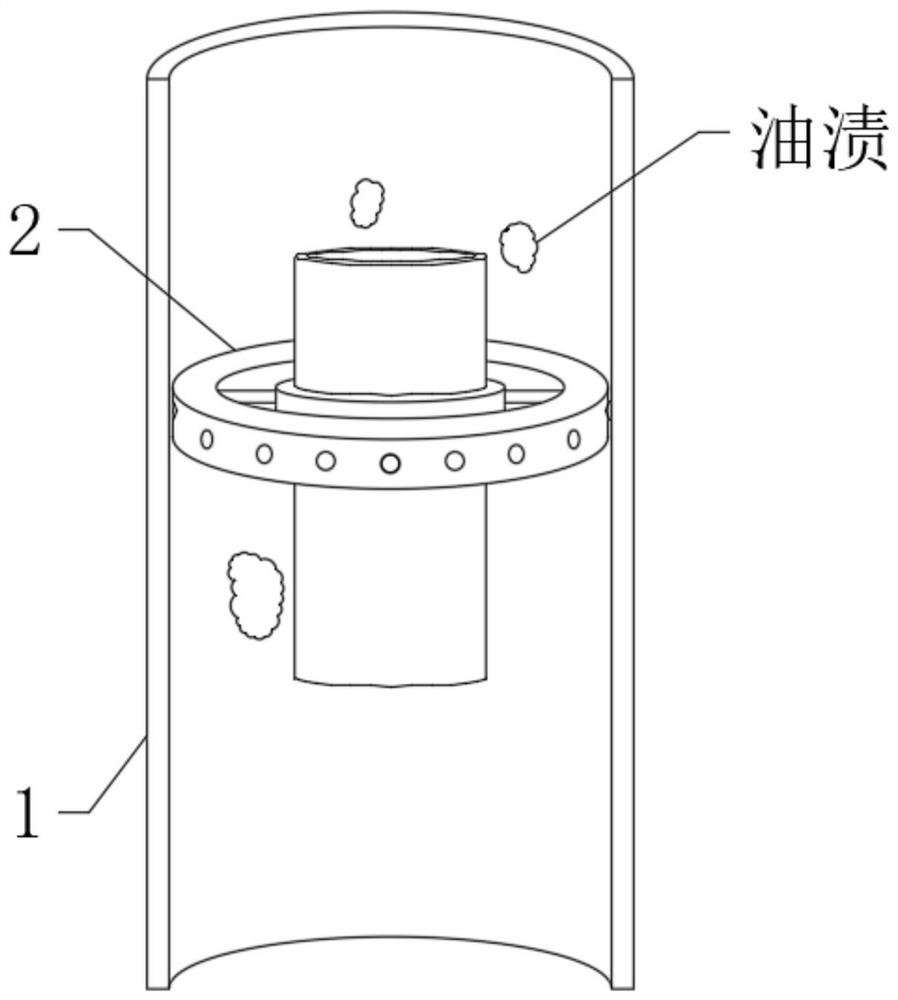

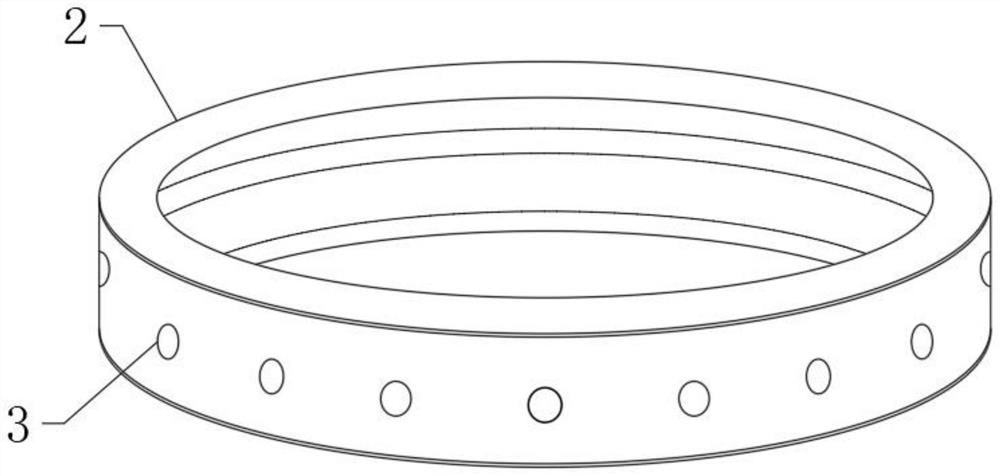

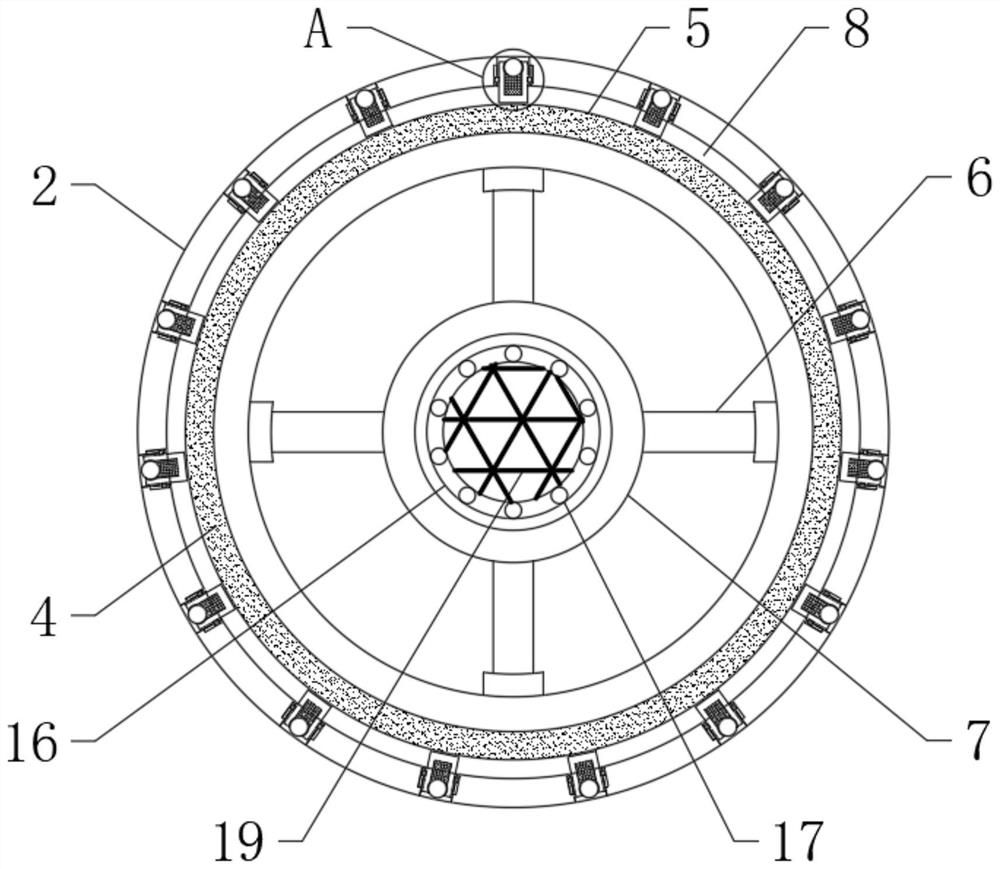

[0042] See Figure 1-2 with Figure 4 , A cleaning device for the inner wall of an exhaust pipe containing oily waste gas, comprising an exhaust pipe 1. The inside of the exhaust pipe 1 is slidably connected with a cleaning ring 2. The outer end of the cleaning ring 2 is dug with a plurality of evenly distributed cleaning holes 3, the cleaning holes A pair of sliding grooves 9 are excavated on the inner wall of 3, and sliding blocks 10 are slidably connected to the inside of the pair of sliding grooves 9, a fixed block 11 is fixedly connected between the pair of sliding blocks 10, and a storage cavity 12 is excavated inside the fixed block 11. The interior of the storage cavity 12 is filled with soap 13, and the upper end of the fixed block 11 is cut with a rolling groove 14 located on the upper side of the storage cavity 12, the rolling groove 14 communicates with the storage cavity 12, and the inside of the rolling groove 14 is connected with rolling balls. 15. The outer end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com