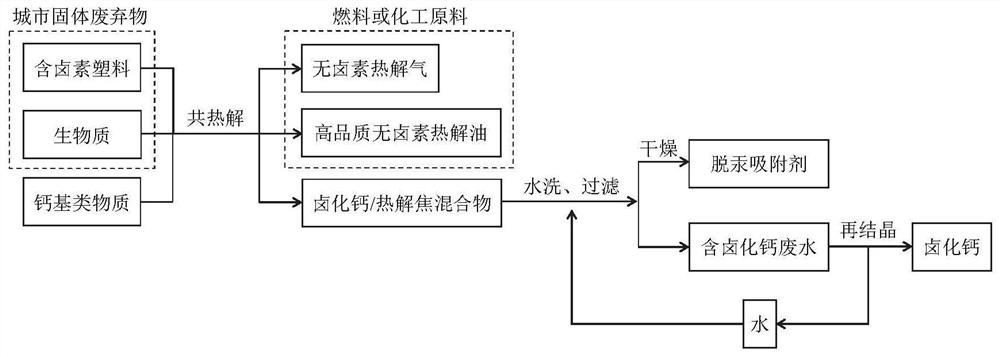

Method for simultaneously preparing high-quality bio-oil and high-performance mercury removal adsorbent from city solid wastes

An adsorbent, high-quality technology, applied in chemical instruments and methods, separation methods, biofuels, etc., can solve the problems of unfavorable mercury removal reaction, blockage of biocoke pore structure, reduction of specific surface area and pore volume, etc., to reduce environmental pollution Contamination, release reduction, viscosity reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1. Crushing and screening waste wood and bamboo and PVC plastics, and selecting wood powder and PVC powder with a particle size of 50 μm to 150 μm for future use.

[0040] Step 2. Mix PVC and wood and bamboo evenly in a ratio of 1:4, then add calcium oxide according to the molar ratio of calcium to chlorine of 2.5, and fully mix the three experimental raw materials evenly.

[0041] Step 3. Put the experimental sample gained in step 2 into the horizontal pyrolysis furnace, and pass into 200ml / min of N 2 As a protective gas, when the pyrolysis furnace rises to 600°C, it starts to pyrolyze and keep it for 20min, then in N 2 Cool to room temperature under atmosphere.

[0042] Step 4. Putting the solid sample obtained in Step 3 into water, stirring thoroughly, and then filtering, and drying the filtered solid to obtain a mercury-removing biocoke adsorbent.

[0043] The specific surface area of the prepared biochar adsorbent is 223.68m 2 / g, the pore volume is 2.02c...

Embodiment 2

[0045] Step 1. Crushing and screening the paper and PVC plastic, and selecting paper powder and PVC powder with a particle size of 100 μm to 200 μm for future use.

[0046] Step 2. Mix PVC and paper evenly in a ratio of 1:10, then add calcium carbonate according to the molar ratio of calcium to chloride as 1, and mix the three experimental raw materials well.

[0047] Step 3. Put the experimental sample obtained in step 2 into a horizontal pyrolysis furnace, and pass into 150ml / min of CO 2 As a protective gas, when the pyrolysis furnace rises to 700°C, it starts pyrolysis and keeps it for 30 minutes, and then in CO 2 Cool to room temperature under atmosphere.

[0048] Step 4. Putting the solid sample obtained in Step 3 into water, stirring thoroughly, and then filtering, and drying the filtered solid to obtain a mercury-removing biocoke adsorbent.

[0049] The specific surface area of the prepared biochar adsorbent is 116.56m 2 / g, the pore volume is 1.03cm 3 / g, the rel...

Embodiment 3

[0051] Step 1. Crushing and screening waste wood and bamboo and computer plastic casings, and selecting wood and bamboo powder and computer plastic casing powder with a particle size of 20 μm to 50 μm for future use.

[0052] Step 2. Mix the plastic shell of the computer with wood and bamboo in a ratio of 1:6, then add calcium hydroxide according to the molar ratio of calcium to chloride of 3, and fully mix the three experimental materials evenly.

[0053] Step 3. Put the experimental sample gained in step 2 into the horizontal pyrolysis furnace, and pass into 200ml / min of N 2 As a protective gas, when the pyrolysis furnace rises to 700°C, it starts to pyrolyze and keep it for 30min, then in N 2 Cool to room temperature under atmosphere.

[0054] Step 4. Putting the solid sample obtained in Step 3 into water, stirring thoroughly, and then filtering, and drying the filtered solid to obtain a mercury-removing biocoke adsorbent.

[0055] The specific surface area of the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com