Anti-ultraviolet polyester fiber composite finishing method

A polyester fiber, anti-ultraviolet technology, applied in the direction of fiber treatment, fiber type, light-resistant fiber, etc., to achieve the effect of high shielding efficiency, stable chemical properties, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

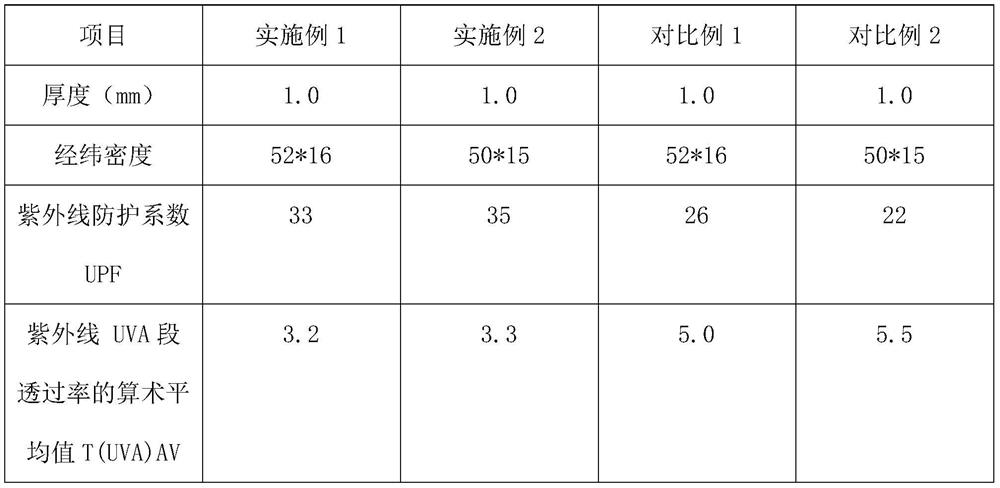

Examples

Embodiment 1

[0024] A kind of anti-ultraviolet polyester fiber composite finishing method provided in this embodiment comprises the following steps:

[0025] 1) Add 500g of polyurethane powder and 20g of tetrabutylammonium hexafluorophosphate into a mixed solvent of N, N-dimethylformamide and acetone, and stir at room temperature at 20°C to make the polymer and tetrabutylammonium hexafluorophosphate completely Dissolved and configured as a spinning mixed solution with a mass fraction of 20%.

[0026] 2) The spinning mixed solution obtained in the step 1) is subjected to high-voltage electrospinning on the substrate to obtain a nano polyester fiber membrane; the voltage of the high-voltage electrospinning is 30kV, and the time is 5h.

[0027] 3) Mix soluble ferric salt, ethanol and water, the volume ratio of ethanol and water is 5:1; the mass concentration of iron element in the iron alkoxide complex solution is 0.03mol / L, to obtain the iron alkoxide complex solution.

[0028] 4) Under the...

Embodiment 2

[0030] A kind of anti-ultraviolet polyester fiber composite finishing method provided in this embodiment comprises the following steps:

[0031] 1) Take 300g of polyacrylonitrile powder and 10g of tetrabutylammonium hexafluorophosphate and add them to a mixed solvent of 20L of N, N-dimethylformamide and 5L of acetone, stir at room temperature 20°C to make the polymer and tetrabutylammonium hexafluorophosphate The ammonium fluorophosphate is completely dissolved and configured as a spinning mixed solution with a mass fraction of 20%.

[0032] 2) The spinning mixed solution obtained in the step 1) is subjected to high-voltage electrospinning on the substrate to obtain a nano polyester fiber membrane; the voltage of the high-voltage electrospinning is 18kV, and the time is 4h.

[0033] 3) Mix soluble ferric salt, ethanol and water, the volume ratio of ethanol and water is 4:1; the mass concentration of iron element in the iron alkoxide complex solution is 0.05mol / L, to obtain the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com