A kind of preparation method of high durability anti-powdering rutile type ultrafine titanium dioxide

An ultra-fine titanium dioxide, durability technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that other physical and chemical properties of rutile titanium dioxide are not tested, and the corrosion resistance and other properties of titanium dioxide cannot be known. The preparation method is cumbersome and other problems, to achieve the effect of high gloss, easy hiding power and tinting power, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

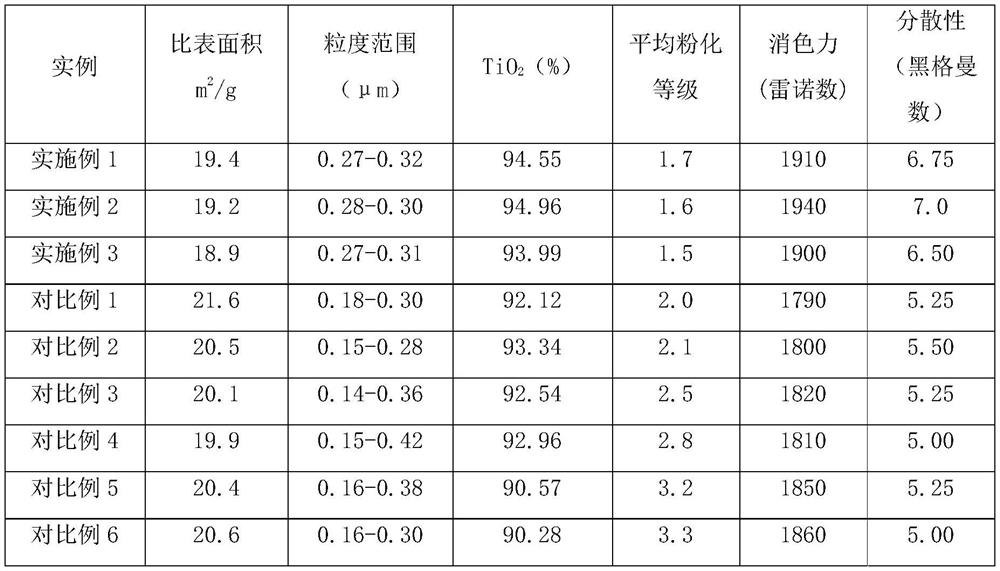

Examples

Embodiment 1

[0038] A preparation method of high durability anti-powdering rutile type ultrafine titanium dioxide, comprising the following steps:

[0039] (1) Dry the titanium concentrate and grind it through a 325 mesh sieve to obtain dry titanium concentrate powder; quantitatively transfer the obtained powder into a mixing tank equipped with concentrated sulfuric acid and mix evenly to obtain a slurry, and then send the slurry into In a continuous acidolysis reactor, waste acid is added for acidolysis to obtain a solid phase; after the solid phase is dissolved, iron powder is added for reduction to obtain a reduced titanium solution A;

[0040](2) Add starch and modified polyacrylamide with a mass ratio of 1:1 to the reduced titanium solution A obtained in step (1) and add starch and modified polyacrylamide to the reduced titanium solution A obtained in step (1). Add antimony white and ferrous sulfide with a mass ratio of 1:1, let it stand until the precipitation is complete, and then f...

Embodiment 2

[0053] A preparation method of high durability anti-powdering rutile type ultrafine titanium dioxide, comprising the following steps:

[0054] (1) Dry the titanium concentrate and grind it through a 325-mesh sieve to obtain dry titanium concentrate powder; quantitatively transfer the obtained powder into a mixing tank equipped with concentrated sulfuric acid and mix it evenly to obtain a slurry, and then send the slurry into In a continuous acidolysis reactor, waste acid is added for acidolysis to obtain a solid phase; after the solid phase is dissolved, iron powder is added for reduction to obtain a reduced titanium solution A;

[0055] (2) Add starch and modified polyacrylamide with a mass ratio of 2:1 to the reduced titanium solution A obtained in step (1) and add starch and modified polyacrylamide to the reduced titanium solution obtained in step (1). Add antimony white and ferrous sulfide with a mass ratio of 1:1, let it stand until the precipitation is complete, and then...

Embodiment 3

[0068] A preparation method of high durability anti-powdering rutile type ultrafine titanium dioxide, comprising the following steps:

[0069] (1) Dry the titanium concentrate and grind it through a 325 mesh sieve to obtain dry titanium concentrate powder; quantitatively transfer the obtained powder into a mixing tank equipped with concentrated sulfuric acid and mix uniformly to obtain a slurry 1, and then mix the slurry 1 Send it into a continuous acidolysis reactor, and add waste acid for acidolysis to obtain a solid phase; dissolve the solid phase and add iron powder for reduction to obtain reduced titanium solution A;

[0070] (2) Add starch and modified polyacrylamide with a mass ratio of 2:1 to the reduced titanium solution A obtained in step (1) and add starch and modified polyacrylamide to the reduced titanium solution obtained in step (1). Add antimony white and ferrous sulfide with a mass ratio of 1:1, let it stand until the precipitation is complete, and then filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com