Ultralow-temperature-resistant rubber and plastic product and preparation method thereof

A rubber and plastic product, ultra-low temperature technology, applied in the field of rubber and plastic products, can solve the problems of poor low temperature resistance of rubber, and achieve the effects of improving resilience, uniform cells, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

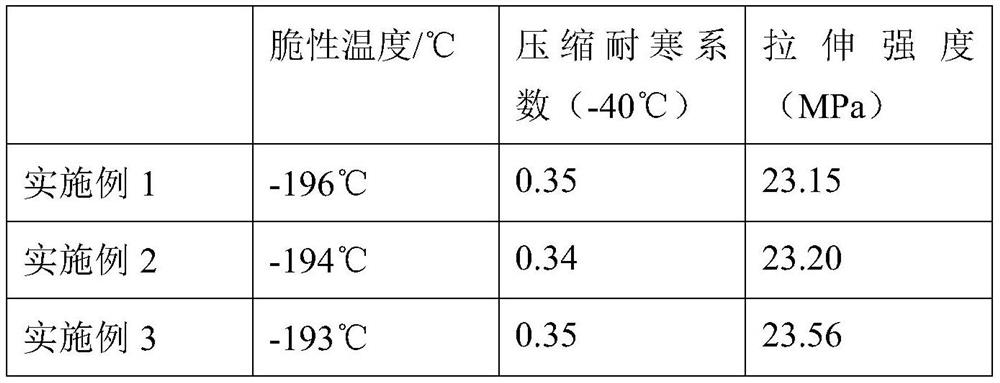

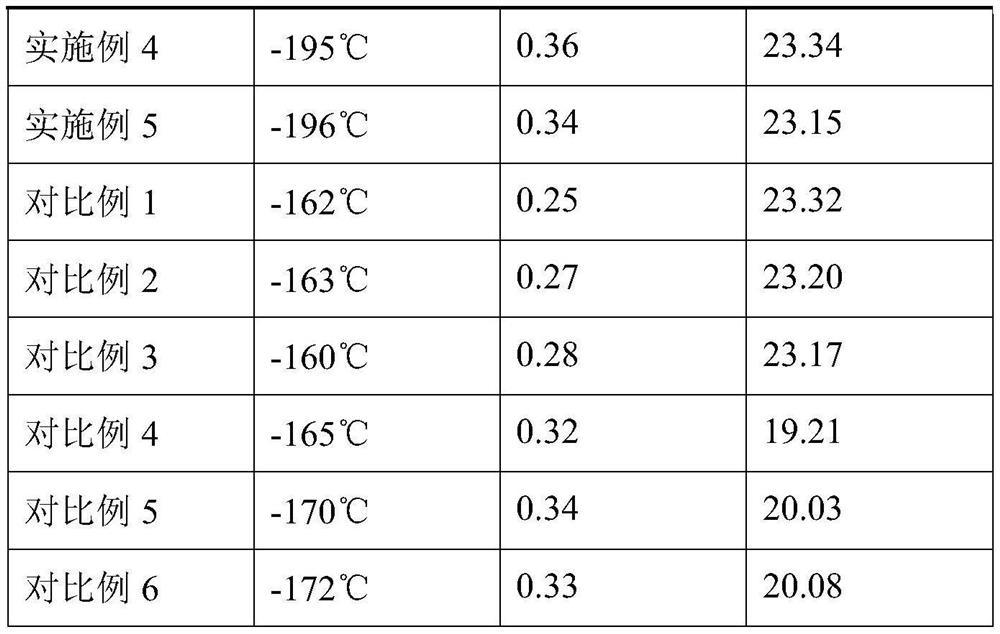

Examples

Embodiment 1

[0024] A kind of ultra-low temperature resistant rubber and plastic product, including 20 parts of EPDM rubber, 5 parts of butyl rubber, 1 part of butadiene rubber, 7 parts of foaming agent, 20 parts of flame retardant, and 8 parts of process oil in parts by mass 4 parts of low-temperature plasticizer, 0.5 part of active agent, 0.1 part of stearic acid, 5 parts of protective wax, 3 parts of accelerator, 0.8 part of vulcanizing agent, and 0.1 part of pigment fast yellow.

[0025] Among them, the foaming agent includes foaming agent DC-W, triammonium citrate, and polyisobutylene succinimide dispersant T155 with a mass ratio of 1:0.8:0.54; the low-temperature plasticizer includes a mass ratio of 0.5:1:1.2 Dibutylmethylene dithioethylene glycol ester, epoxy tall oil fatty acid 2-ethylhexyl ester, polyethylene glycol monomethyl ether acrylate; accelerators include accelerators with a mass ratio of 1:1.1 NA-22 and accelerator TMTD; the vulcanizing agent includes sulfur and bis(1,5-p...

Embodiment 2

[0032] A kind of ultra-low temperature resistant rubber and plastic product, including 25 parts of EPDM rubber, 3 parts of butyl rubber, 1.5 parts of butadiene rubber, 5 parts of foaming agent, 30 parts of flame retardant, and 6 parts of process oil in parts by mass 7 parts, 7 parts of low temperature plasticizer, 0.3 part of active agent, 0.3 part of stearic acid, 3 parts of protective wax, 5 parts of accelerator, 0.5 part of vulcanizing agent, 0.2 part of pigment phthalocyanine.

[0033] Among them, the foaming agent includes foaming agent DC-W, triammonium citrate, and polyisobutylene succinimide dispersant T155 with a mass ratio of 1:1:0.25; the low-temperature plasticizer includes a mass ratio of 0.85:1:1 Dibutylmethylene dithioethylene glycol ester, epoxy tall oil fatty acid 2-ethylhexyl ester, polyethylene glycol monomethyl ether acrylate; accelerators include accelerators with a mass ratio of 1:1.14 NA-22 and accelerator TMTD; the vulcanizing agent includes sulfur and ...

Embodiment 3

[0040]A kind of ultra-low temperature resistant rubber and plastic product, including 22 parts of EPDM rubber, 4 parts of butyl rubber, 1.2 parts of butadiene rubber, 6 parts of foaming agent, 25 parts of flame retardant, and 7 parts of process oil in parts by mass 5 parts, 5 parts of low temperature plasticizer, 0.4 part of active agent, 0.2 part of stearic acid, 4 parts of protective wax, 4 parts of accelerator, 0.7 part of vulcanizing agent, 0.15 part of pigment phthalogreen.

[0041] Among them, the foaming agent includes foaming agent DC-W, triammonium citrate, and polyisobutylene succinimide dispersant T155 with a mass ratio of 1:0.9:0.3; the low-temperature plasticizer includes a mass ratio of 0.6:1:1.1 Dibutylmethylene dithioethylene glycol ester, epoxy tall oil fatty acid 2-ethylhexyl ester, polyethylene glycol monomethyl ether acrylate; accelerators include accelerators with a mass ratio of 1:1.12 NA-22 and accelerator TMTD; the vulcanizing agent includes sulfur and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com