Modified asphalt coating material with excellent high and low temperature performance, waterproof roll and preparation method thereof

A modified asphalt, high and low temperature technology, applied in chemical instruments and methods, coatings, building components, etc., can solve the problems of organic solvent environment and production worker injury, unclear low temperature resistance, complex preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

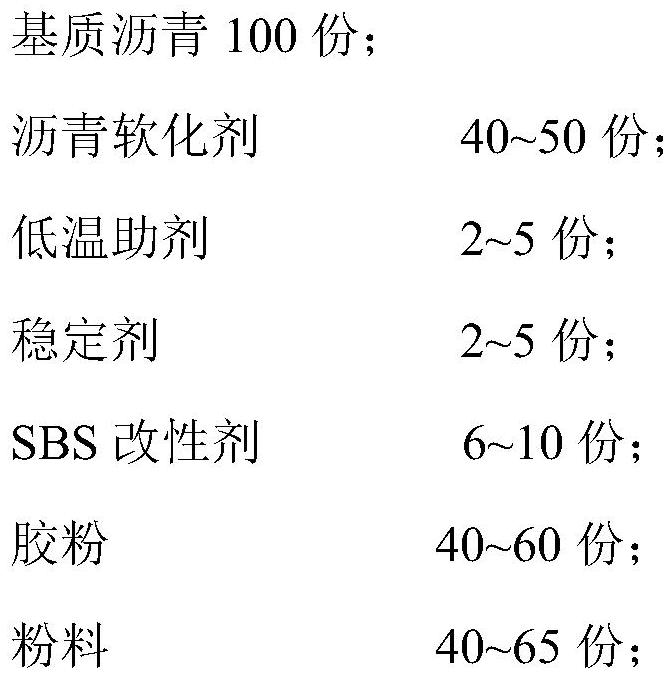

[0062] This embodiment provides a modified asphalt waterproof membrane with excellent high and low temperature performance, including a base layer, a coating layer covering the upper and lower surfaces of the base layer, and a protective film covering the surface of the coating layer layer, the coating layer is a modified asphalt coating material with excellent high and low temperature performance, which includes the following components calculated by weight:

[0063] 100 parts of 90# asphalt;

[0064] 35 parts of 200# asphalt;

[0065] 5 parts of rubber oil;

[0066] 1 part castor oil;

[0067] 1 part tea tree oil;

[0068] Fatty acid sorbitan 2 parts;

[0069] 7 parts of SBS modifier;

[0070] 48 parts of tire rubber powder;

[0071] Heavy calcium 54 parts.

[0072] The above-mentioned modified asphalt coating material is prepared by the following method, including the following steps:

[0073] A1 Mix 90# asphalt, 200# asphalt, rubber oil, castor oil, tea tree oil, a...

Embodiment 2

[0082] This example provides a modified asphalt waterproofing membrane with excellent high and low temperature performance. The difference between it and Example 1 is that the asphalt softener added to the modified asphalt coating material uses F400# asphalt and rubber oil , the low-temperature auxiliary agent adopts soybean oil, the stabilizer adopts short glass fiber, and the powder material adopts talcum powder, specifically, includes the following components calculated by weight:

[0083] 100 parts of 90# asphalt;

[0084] F400# asphalt 25 parts;

[0085] 20 parts of rubber oil;

[0086] 3 parts soybean oil;

[0087] 5 parts of short glass fiber;

[0088] 7 parts of SBS modifier;

[0089] 48 parts of tire rubber powder;

[0090] 45 parts of talcum powder.

[0091] The above-mentioned modified asphalt coating material is prepared by the following method, including the following steps:

[0092] A1 Mix 90# asphalt, F400# asphalt, rubber oil, soybean oil and short glass...

Embodiment 3

[0097] This example provides a modified asphalt waterproofing membrane with excellent high and low temperature performance. The difference between it and Example 2 is that soybean oil and industrial white oil are used as low-temperature additives in the modified asphalt coating material. , the powder adopts talcum powder, specifically, includes the following components calculated in parts by weight:

[0098] 100 parts of 90# asphalt;

[0099] 20 parts of F400# asphalt;

[0100] 20 parts of rubber oil;

[0101] 2 parts soybean oil;

[0102] 1 part industrial white oil;

[0103] 5 parts of short glass fiber;

[0104] 7 parts of SBS modifier;

[0105] 48 parts of tire rubber powder;

[0106] 50 parts of talcum powder.

[0107] The above-mentioned modified asphalt coating material is prepared by the following method, including the following steps:

[0108] A1 Mix 90# asphalt, F400# asphalt, rubber oil, soybean oil, industrial white oil and short glass fiber according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com