Bismuth ferrite/polyvinylidene fluoride-trifluoroethylene multilayer composite film and preparation method thereof

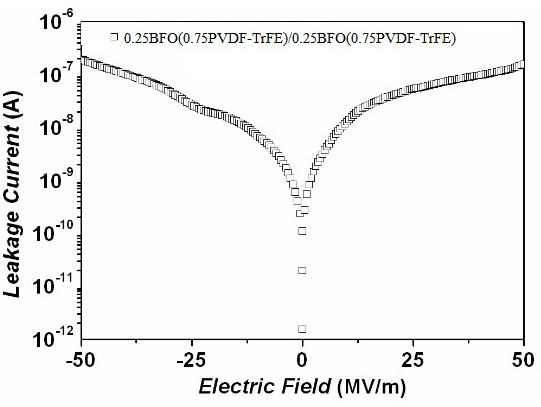

A polyvinylidene fluoride and trifluoroethylene technology, applied in semiconductor/solid-state device manufacturing, coating, electric solid-state devices, etc., can solve the problems of high remanent polarization, high coercive field, large leakage current, etc. Achieve the effect of solving large leakage current, simple preparation method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing a bismuth ferrite / polyvinylidene fluoride-trifluoroethylene composite film, comprising the following steps:

[0042] S1, preparing nanoscale BFO nanoscale powder;

[0043] S1.1. Dissolve bismuth nitrate pentahydrate and ferric nitrate nonahydrate in ethylene glycol methyl ether solvent at a molar ratio of 1.05:1 to obtain solution C with a concentration of 0.5 mol / L; Dissolve citric acid and polyethylene glycol in the continuously stirring solution C, the molar ratio of citric acid monohydrate to metal cations in the solution is 1:1, the mass ratio of polyethylene glycol to citric acid monohydrate is 1:8, and Bismuth ferrite precursor solution;

[0044] S1.2. The obtained bismuth ferrite precursor solution was continuously stirred in a 50°C water bath for 30 minutes to obtain a stable bismuth ferrite sol, and then dried in a drying oven at 80°C for 48 hours to obtain a bismuth ferrite xerogel;

[0045] S1.3. Place the obta...

Embodiment 2

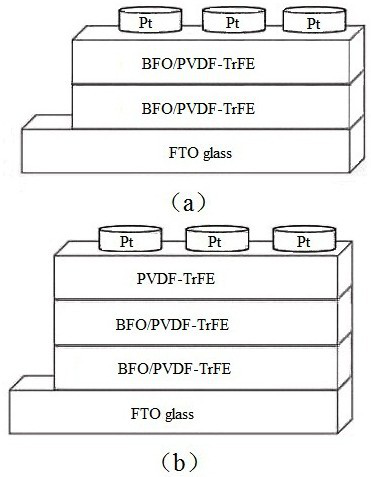

[0057] This embodiment provides a bismuth ferrite / polyvinylidene fluoride-trifluoroethylene multilayer composite film comprising two layers of BFO / PVDF-TrFE composite film and PVDF-TrFE film, and the two layers of BFO / PVDF-TrFE composite film are stacked in sequence combined and located on the uppermost BFO / PVDF-TrFE composite film with a PVDF-TrFE film attached.

[0058] The preparation method of the above-mentioned bismuth ferrite / polyvinylidene fluoride-trifluoroethylene multilayer composite film comprises the following steps:

[0059] S1, preparing nanoscale BFO nanoscale powder;

[0060] S1.1. Dissolve bismuth nitrate pentahydrate and ferric nitrate nonahydrate in ethylene glycol methyl ether solvent at a molar ratio of 1.05:1 to obtain solution C with a concentration of 0.5 mol / L; Dissolve citric acid and polyethylene glycol in the continuously stirring solution C, the molar ratio of citric acid monohydrate to metal cations in the solution is 1:1, the mass ratio of poly...

Embodiment 3

[0075] This embodiment provides a method for preparing bismuth ferrite / polyvinylidene fluoride-trifluoroethylene composite film, comprising the following steps:

[0076] S1, preparing nanoscale BFO nanoscale powder;

[0077] S1.1. Dissolve bismuth nitrate pentahydrate and ferric nitrate nonahydrate in ethylene glycol methyl ether solvent at a molar ratio of 1.05:1 to obtain solution C with a concentration of 0.5 mol / L; Citric acid and polyethylene glycol were dissolved in solution C that was continuously stirred, the molar ratio of citric acid monohydrate to metal cations in the solution was 1:1, and the mass ratio of polyethylene glycol to citric acid monohydrate was 1:8, and Bismuth ferrite precursor solution;

[0078] S1.2. The obtained bismuth ferrite precursor solution was continuously stirred in a 50°C water bath for 30 minutes to obtain a stable bismuth ferrite sol, and then dried in a drying oven at 80°C for 48 hours to obtain a bismuth ferrite xerogel;

[0079] S1.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com