Method for preparing cyclohexyl isocyanate from solid phosgene

A technology of solid phosgene and isocyanic acid, which is applied in the preparation of isocyanic acid derivatives, chemical instruments and methods, preparation of organic compounds, etc. problem, to achieve high competitive advantage, no significant toxicity, chemical stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

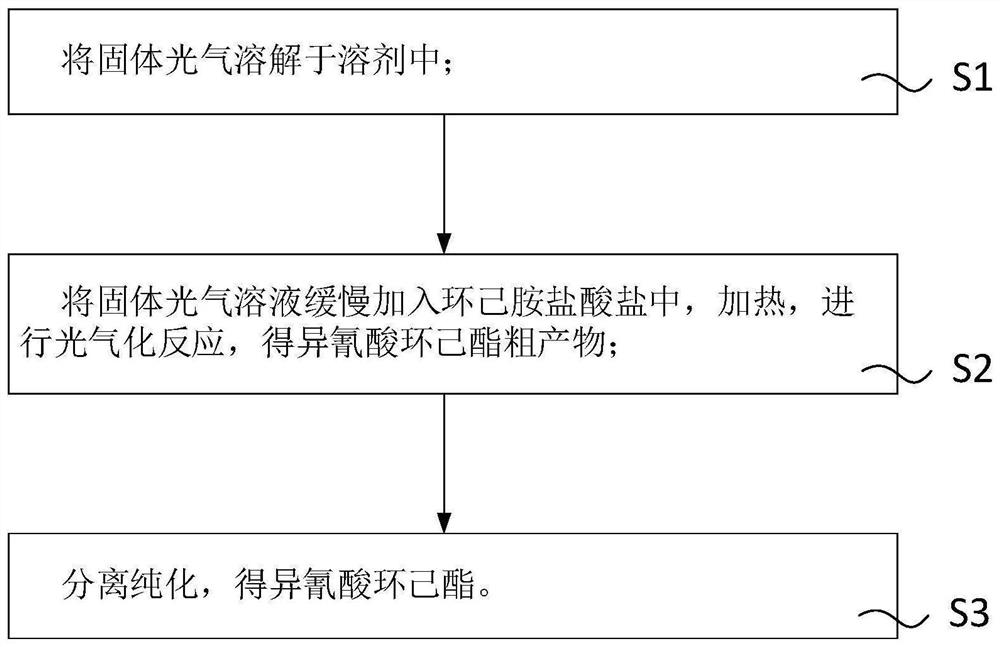

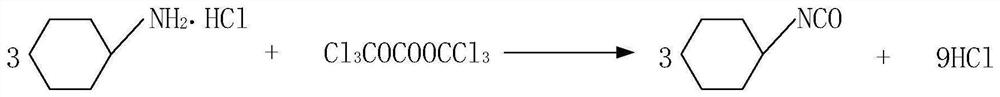

[0044] The invention provides a kind of method that solid phosgene prepares cyclohexyl isocyanate, comprises the steps:

[0045] S1. Put 151g of solid phosgene into a four-necked flask, add toluene into the solid phosgene, and dissolve the solid phosgene in the toluene solvent; wherein, the mass ratio of solid phosgene to toluene is 1.15:1; it is used to dissolve solid The system temperature of phosgene is 30°C;

[0046] S2. Slowly add the toluene solution containing 151g of solid phosgene to a 2000ml four-neck flask equipped with cyclohexylamine hydrochloride at a rate of 3ml / min, heat to 100°C, and conduct the reaction between solid phosgene and cyclohexylamine hydrochloride. Phosgenation reaction until the solution in the four-necked flask is clarified to obtain the crude product of cyclohexyl isocyanate; wherein, the rate of addition of the toluene solution of solid phosgene is controlled so that the slight negative pressure of the phosgenation reaction system is -80mm wat...

Embodiment 2

[0057] S1. Put 151g of solid phosgene into a four-necked flask, add toluene into the solid phosgene, and dissolve the solid phosgene in the toluene solvent; wherein, the mass ratio of solid phosgene to toluene is 1.15:1; it is used to dissolve solid The system temperature of phosgene is 30°C;

[0058] S2, in the 2000ml four-neck flask that cyclohexylamine hydrochloride is housed, add 4g triethylamine catalyst, the toluene solution that will contain 151g solid phosgene is slowly added with the speed of 3ml / min and cyclohexylamine hydrochloride is housed , heated to 100°C, the solid phosgene and cyclohexylamine hydrochloride undergo phosgenation until the solution in the four-necked flask is clear, and the crude product of cyclohexyl isocyanate is obtained; among them, the toluene solution of the solid phosgene is controlled The addition rate makes the slight negative pressure of the phosgenation reaction system -80mm water column;

[0059] S3. Separating and purifying the cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com