Thin plate grinding machine rolling structure

A grinding machine and thin plate technology, which is applied in the direction of grinding machine tools, grinding devices, grinding racks, etc., can solve the problems of increasing material and labor costs, inconvenient replacement and use, etc., and achieve the effect of convenient processing and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

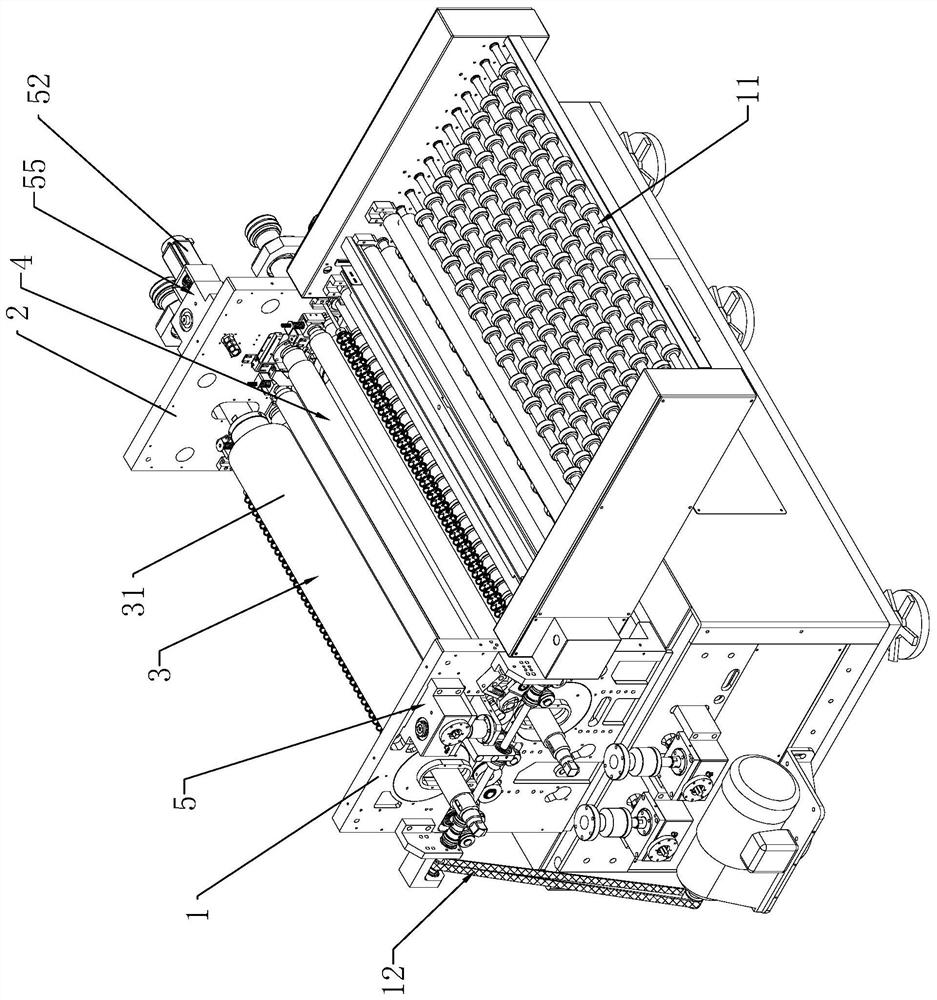

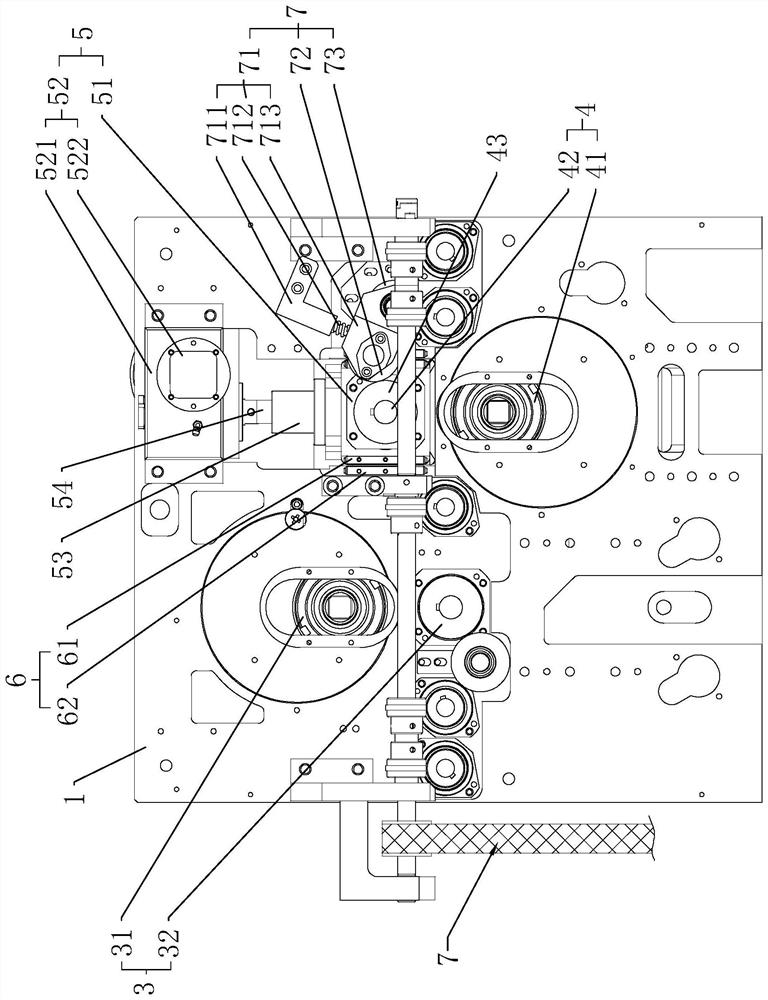

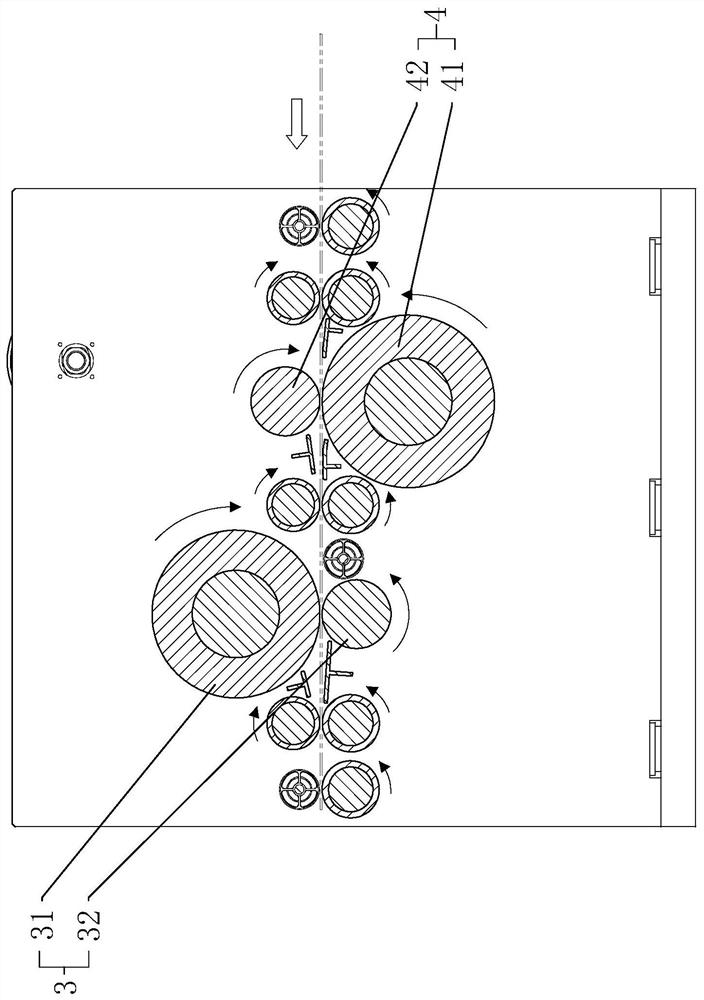

[0030] The rolling structure of a thin plate grinder disclosed in the present invention adjusts the vertical movement of the first back pressure wheel 42, thereby adjusting the distance between the first back pressure wheel 42 and the first roller 41, so that it can be used for different thicknesses. Sheets are processed. Such as figure 1 As shown, it includes the second grinding group 3 and the first grinding group 4 arranged between the first side plate 1 and the second side plate 2, the second grinding group 3 and the first grinding group 4 are horizontal And arranged side by side, the thin plate enters the second brushing group 3 through the first brushing group 4 . One end of the first side plate 1 and the second side plate 2 is jointly provided with a conveying section 11, and the conveying end is composed of a plurality of horizontally spaced round r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com