Yarn feeding device

A technology for feeding device and yarn, which is applied in the field of yarn feeding device to achieve the effect of convenient adjustment and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

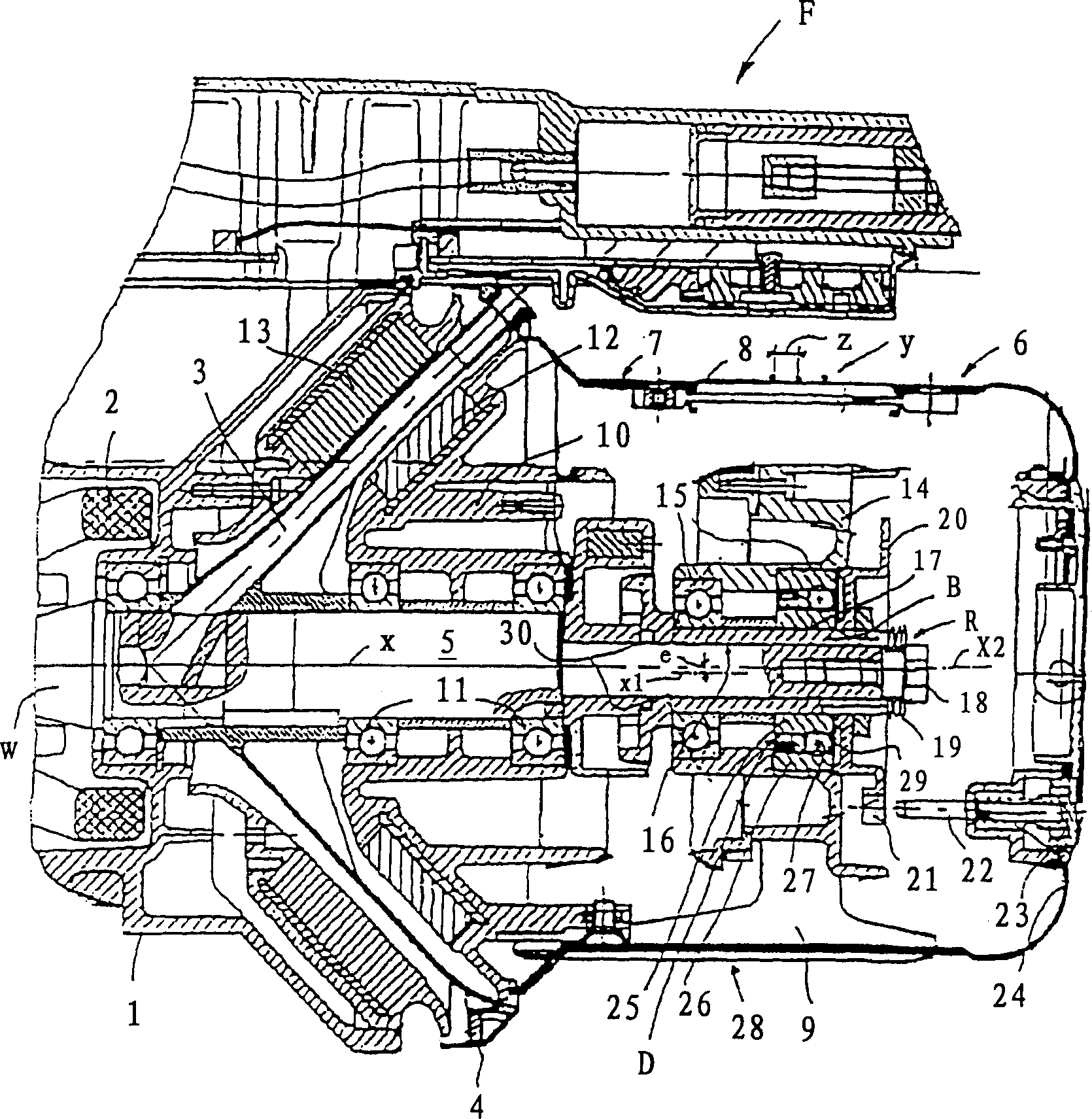

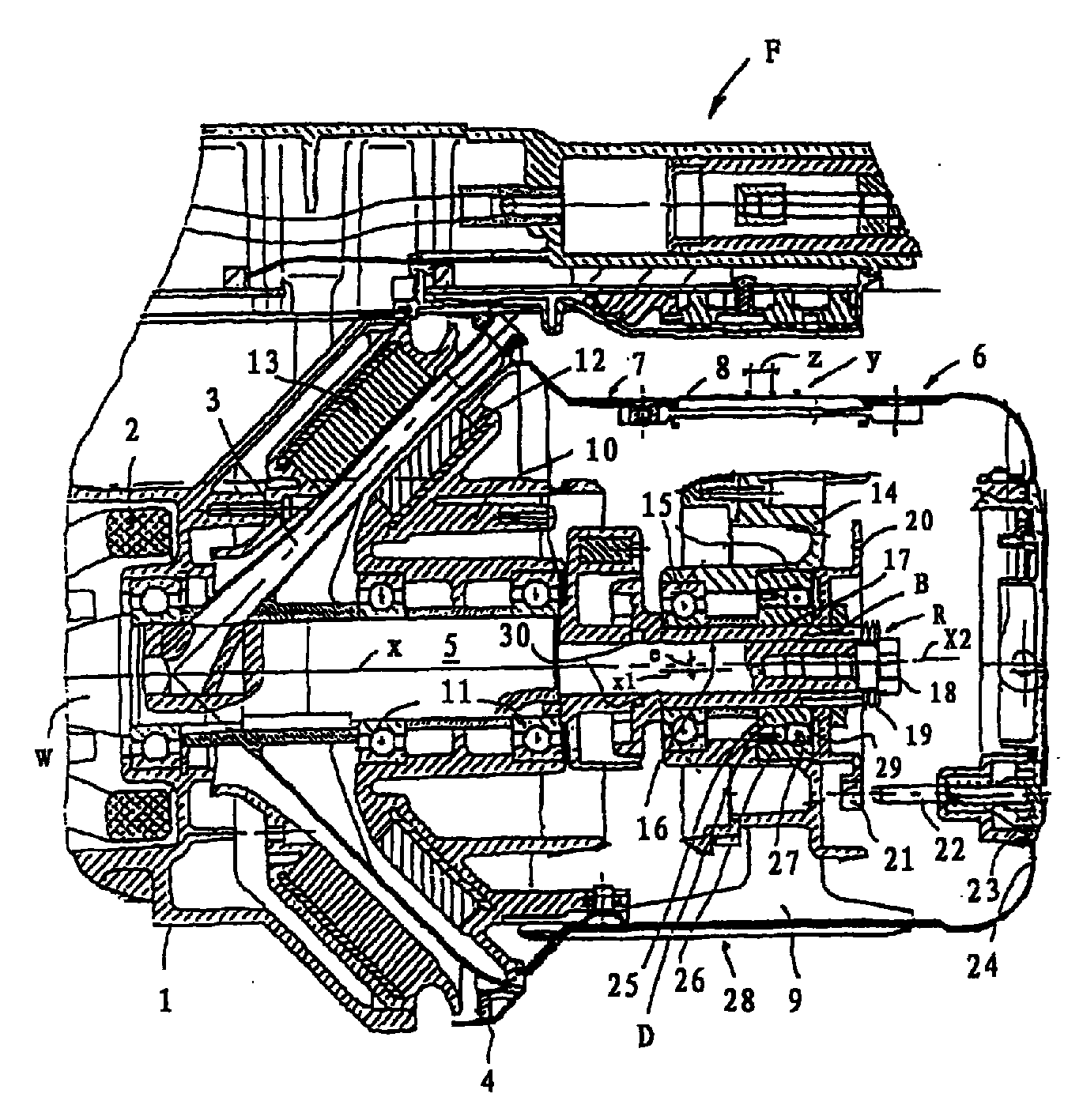

[0021] figure 1 The yarn feeding device F in has a motor housing 1 which contains a motor 2 which drives a drive shaft W so that it rotates about an axis X in a selected direction of rotation. A winding element 3 , for example a winding tube, is arranged on the drive shaft W, terminates outside the motor housing 1 and extends from the hollow drive shaft W obliquely outwards. Such a winding element is arranged in a so-called winding disk 4, which is arranged on the drive shaft W and is located between the motor housing 1 and a storage drum 6 which passes through the drive shaft W. W is supported on the motor case 1 . The drive shaft W serves as a carrier for the storage drum 6 and has a coaxial extension 5 for this purpose.

[0022] The storage drum 6 is composed of two intermeshing rod-cage cylinders, that is, one is a support rod-cage cylinder 7 with several axial rods 8 spaced apart in the circumferential direction, and the other is a support rod-cage cylinder 7 with sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com