Design method of ultrasonic surface standing wave micro-fluidic chip for micro-particle separation

A microfluidic chip and ultrasonic surface wave technology, applied in the field of microfluidic analysis, can solve the problems of wasting time and cost, and low particle separation efficiency, and achieve the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

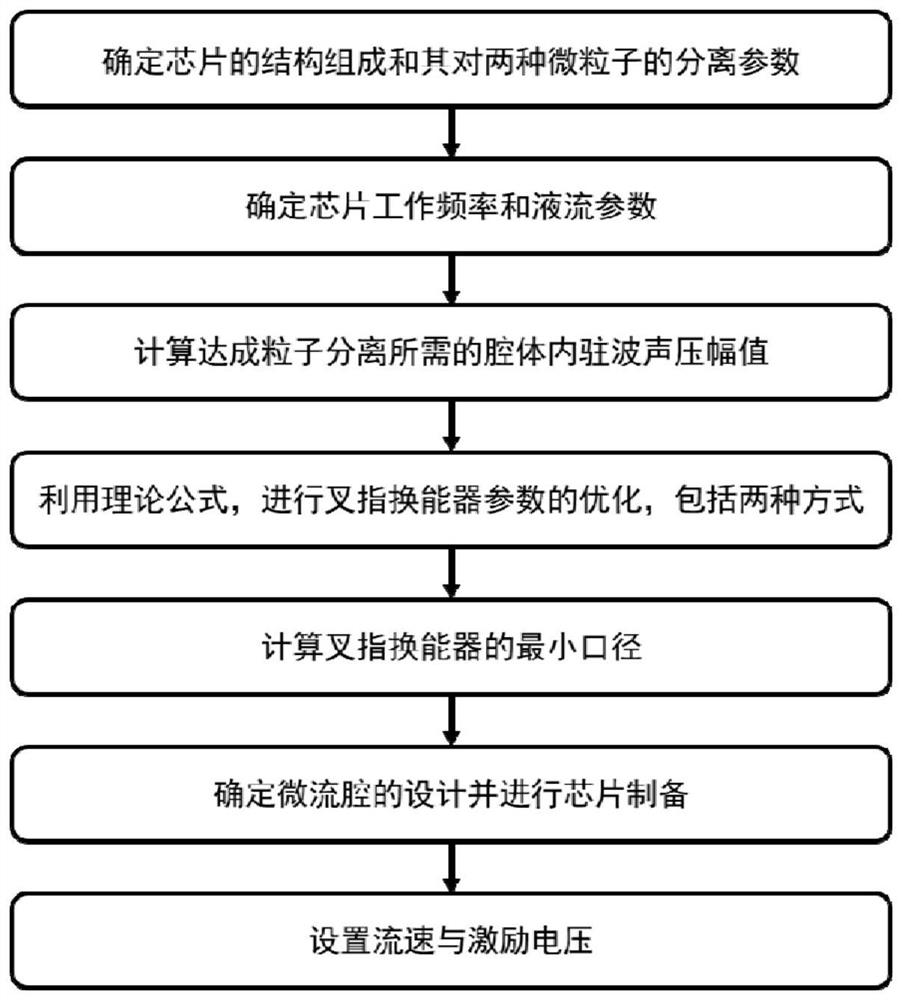

Method used

Image

Examples

Embodiment 1

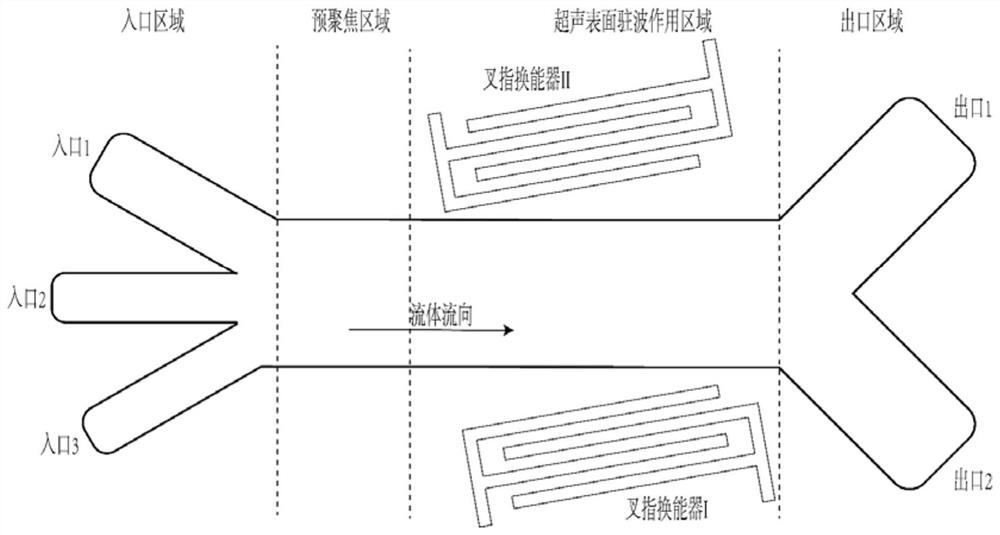

[0048] This embodiment specifically describes an ultrasonic surface standing wave microfluidic chip, which includes a piezoelectric substrate, an interdigital transducer, a microfluidic cavity, and a driving circuit. The interdigital transducer is attached to the piezoelectric substrate, and the interdigital transducer is attached to the piezoelectric substrate. The device emits ultrasonic surface waves, forming a standing field wave on the surface of the substrate, and applies ultrasonic radiation force to the fluid particles in the microfluidic cavity; the microfluidic cavity is bonded or glued to the piezoelectric substrate, and the internal channel section of the microfluidic cavity is rectangular; The driving circuit drives the interdigital transducer to work. The particles enter the microfluidic cavity of the microfluidic chip using the sheath flow technology known in the art. Under the action of the ultrasonic surface standing wave, different types of particles present di...

Embodiment 2

[0071] This embodiment is basically the same as embodiment 1, except that the two particle radii of this embodiment are closer, and the microfluidic chip of this embodiment is a PM-SSAW chip.

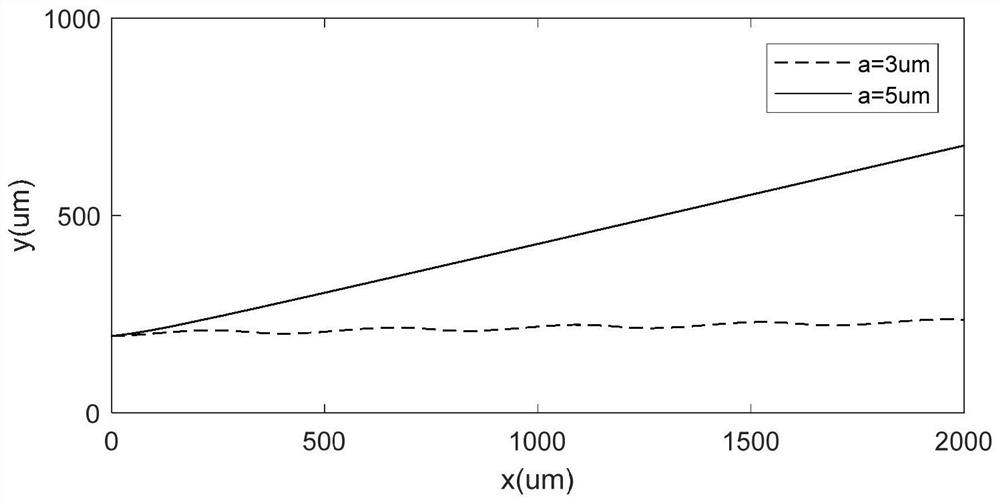

[0072] In this implementation, polystyrene (PS) microspheres with a radius of 3 μm and 3.8 μm are separated. Requires separation purity d> 0.95, particle flux P=100 particles / sec. According to the parameters of the particles to be separated, the cavity size, particle fluid flow rate and ultrasonic action area width of the microfluidic cavity of the chip are calculated. Specific steps are as follows:

[0073] Step 1. Determine the structure of the chip and its separation parameters for the two kinds of particles:

[0074] A 128°Y tangential lithium niobate crystal sheet with a thickness of 0.5 mm was selected to prepare the piezoelectric substrate of the microfluidic chip, and PDMS was selected as the material of the microfluidic cavity channel wall of the chip. Pre-focusing of microparticle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com