Size-adjustable palladium-based catalyst limited by carbon nanotubes as well as preparation method and application of size-adjustable palladium-based catalyst

A carbon nanotube and catalyst technology, which is applied in the field of size-adjustable palladium-based catalyst and its preparation, can solve the problems of lack of metal nanoclusters or metal single atoms, intercalation, etc., and achieves the improvement of atom utilization efficiency, and the method is simple and easy to implement. The effect of large reaction residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

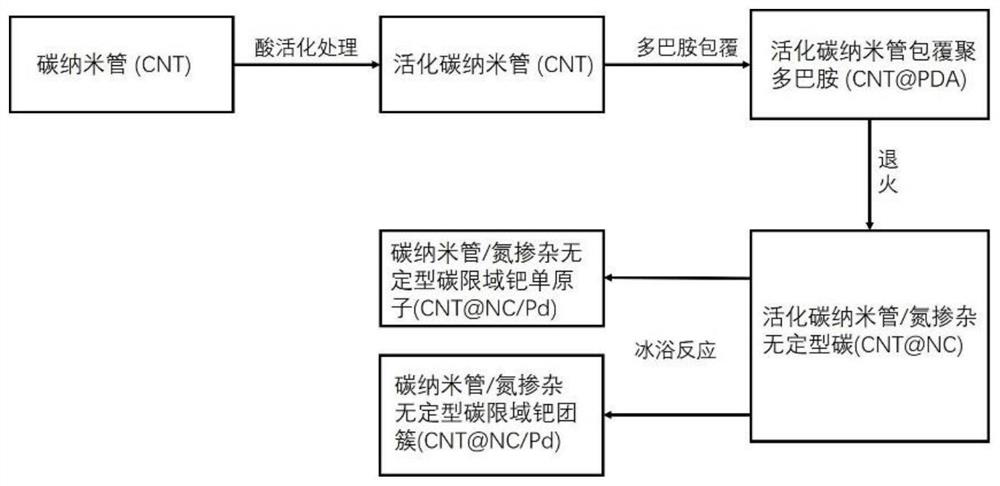

Method used

Image

Examples

Embodiment 1

[0028] (1) 2 g of carbon nanotubes were placed in a mixed solution of 120 mL of concentrated sulfuric acid and 40 mL of concentrated nitric acid, and heated and acidified at 60 °C for 3 hours. Then suction filtration washing and dialysis until the pH of the dispersion is close to neutral;

[0029] (2) Take 100 mL of the carbon nanotube dispersion with a concentration of 1 mg / mL in a beaker, add 121 mg of tris (Tris) and 200 mg of dopamine hydrochloride, and keep stirring for 12 hours to make the dopamine hydrochloride Polydopamine is polymerized to form polydopamine and wrapped on carbon nanotubes to obtain CNT@PDA composite materials;

[0030] (3) The obtained CNT@PDA composite material was annealed at 800 °C for 1 hour under the protection of an inert gas atmosphere, so that the polydopamine PDA component in it was annealed to form nitrogen-doped carbon, and CNT@ NC composite materials;

[0031] (4) Disperse the obtained CNT@NC composite material in deionized water to prep...

Embodiment 2

[0035] (1) 2 g of carbon nanotubes were placed in a mixed solution of 160 mL of concentrated sulfuric acid and 40 mL of concentrated nitric acid, and heated and acidified at 65 °C for 2 hours. Then suction filtration washing and dialysis until the pH of the dispersion is close to neutral;

[0036](2) Take 100 mL of the carbon nanotube dispersion with a concentration of 1 mg / mL in a beaker, add 121 mg of tris (Tris) and 200 mg of dopamine hydrochloride, and keep stirring for 24 hours to make the dopamine hydrochloride Polydopamine is polymerized to form polydopamine and wrapped on carbon nanotubes to obtain CNT@PDA composite materials;

[0037] (3) The obtained CNT@PDA composite material was annealed at 1000 °C for 2 hours under the protection of an inert gas atmosphere, so that the polydopamine PDA component in it was annealed to form nitrogen-doped carbon, and CNT@ NC composite materials;

[0038] (4) Disperse the obtained CNT@NC composite material in deionized water to pre...

Embodiment 3

[0042] (1) 2 g of carbon nanotubes were placed in a mixed solution of 120 mL of concentrated sulfuric acid and 40 mL of concentrated nitric acid, and heated and acidified at 65 °C for 2 hours. Then suction filtration washing and dialysis until the pH of the dispersion is close to neutral;

[0043] (2) Take 100 mL of the carbon nanotube dispersion with a concentration of 2 mg / mL in a beaker, add 242 mg of tris (Tris) and 150 mg of dopamine hydrochloride, and keep stirring for 24 hours to make the dopamine hydrochloride Polydopamine is polymerized to form polydopamine and wrapped on carbon nanotubes to obtain CNT@PDA composite materials;

[0044] (3) The obtained CNT@PDA composite material was annealed at 1000 °C for 2 hours under the protection of an inert gas atmosphere, so that the polydopamine PDA component in it was annealed to form nitrogen-doped carbon, and CNT@ NC composite materials;

[0045] (4) Disperse the obtained CNT@NC composite material in deionized water to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com