Drive unit box

An accessory transmission and centrifugal technology, applied in transmission parts, crankcase ventilation, engine components, etc., can solve problems such as inability to compactly locate adjacent units, increase AGB outline size and weight, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

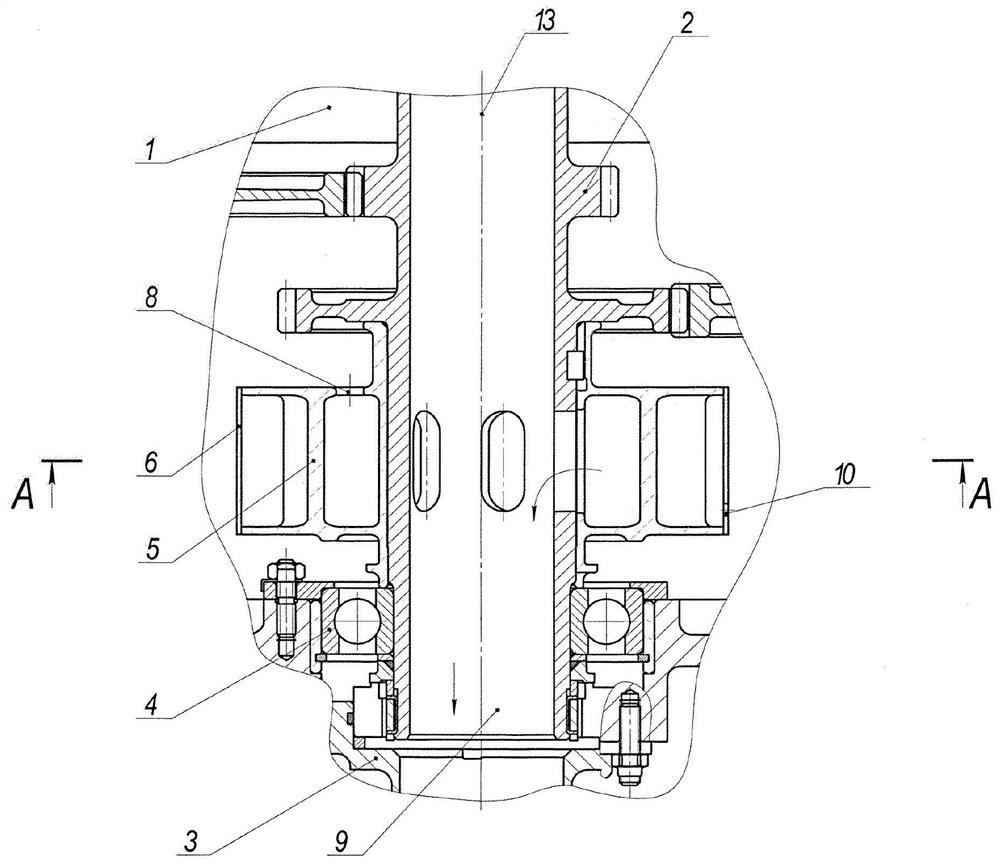

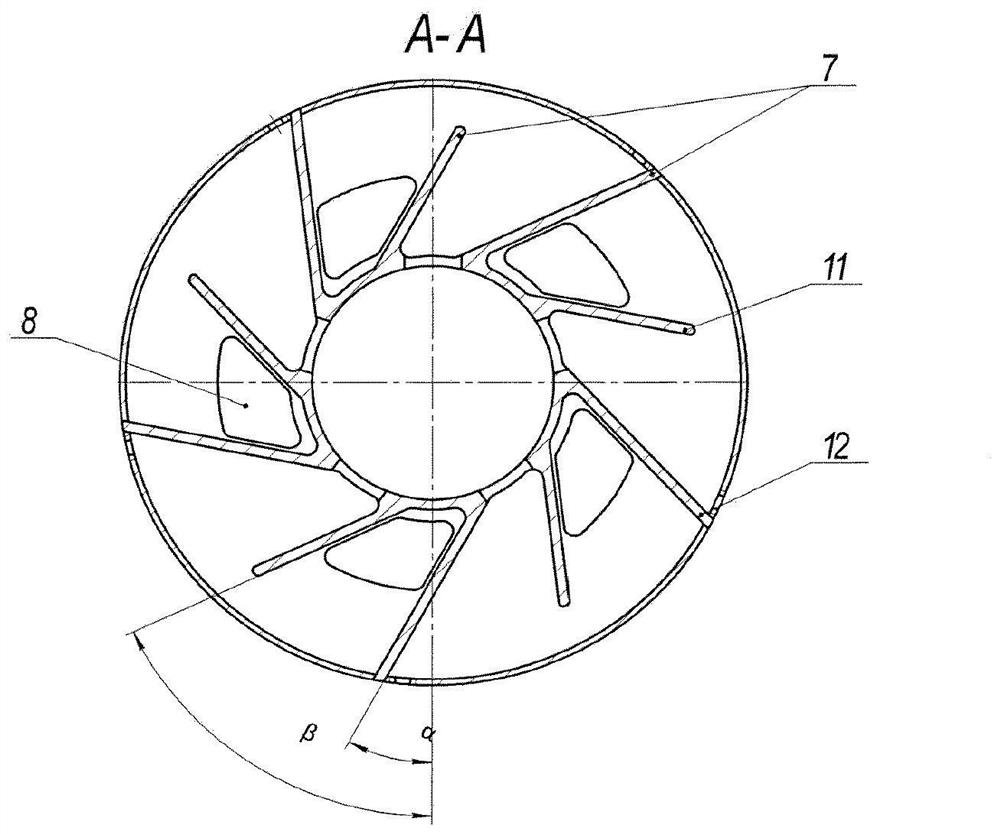

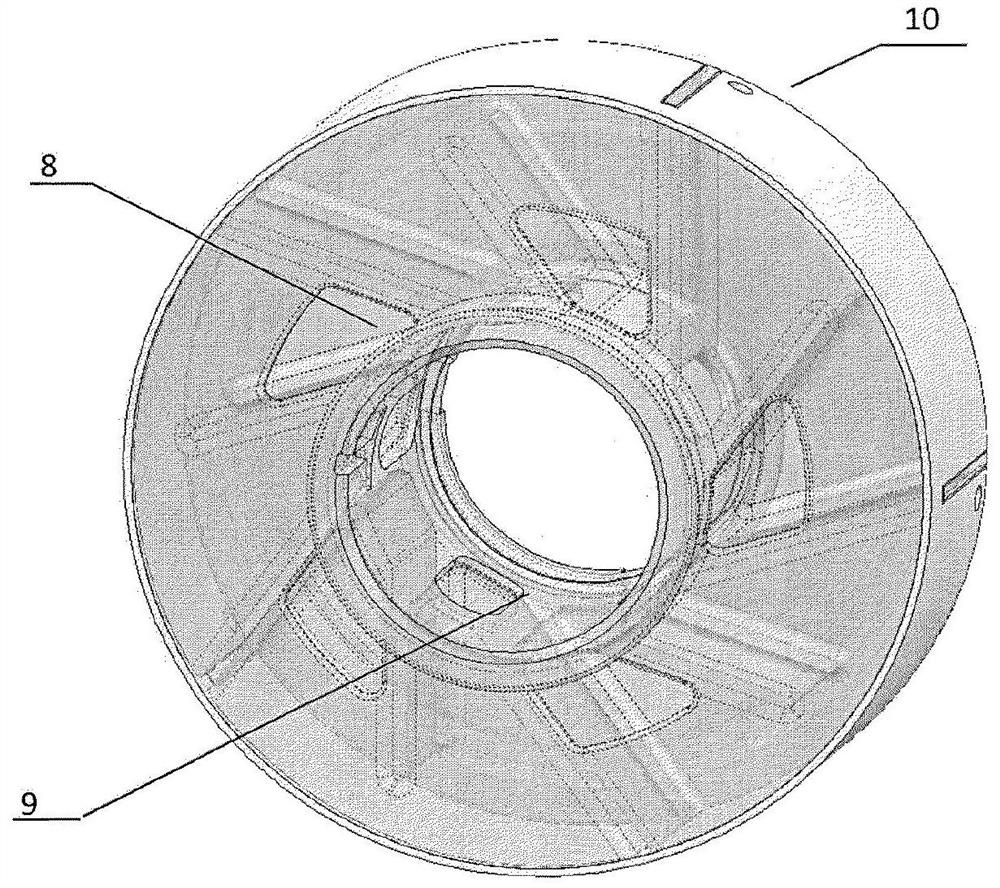

[0015] Accessory gearbox 1 ( figure 1 , figure 2 , image 3 ) contains a gear 2, a branch pipe 3, a bearing 4, a centrifugal impeller 5 with blades 7; the centrifugal impeller contains a casing 6 which can form a cavity, and a window 8 for the inlet of the air-oil mixture, an air outlet window 9 and openings 10 for draining separated oil; the blades 7 of the impeller 5 are made with different lengths 11 , 12 and are positioned at angles α and β with respect to the axis of rotation 13 of the gear 2 .

[0016] The accessory gearbox is designed to operate as follows.

[0017] The centrifugal breather (without position marking) located in the housing 1 of the accessory transmission box contains the gear 2 on which the centrifugal impeller 5 is mounted. The centrifugal impeller has a housing 6 and blades 7 of different lengths 11, 12 positioned at different angles α and β to the axis of the gear 2, which lead to the formation of interconnected adjacent cavities, the windows of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com